Why manufacturers are quietly upgrading to Twill Weave Mesh

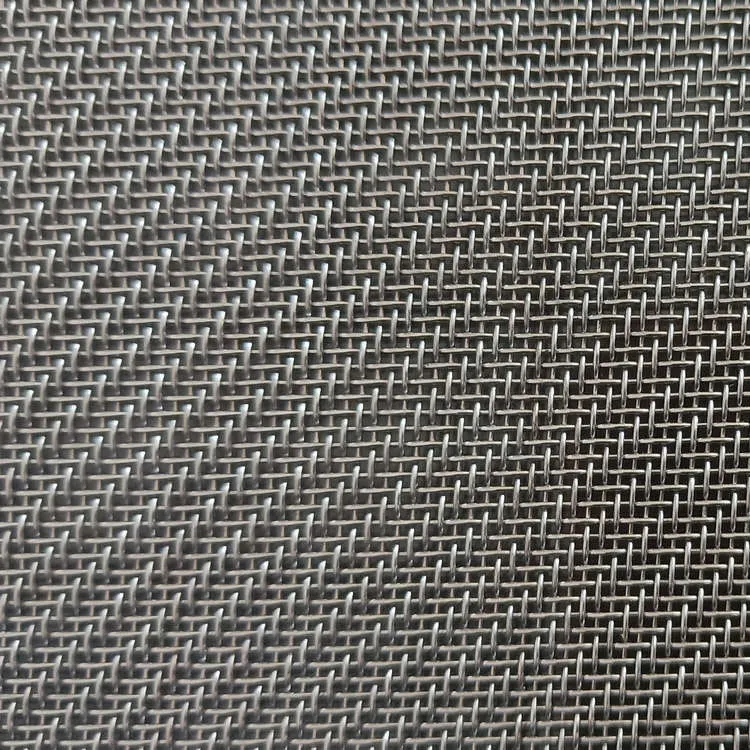

There’s a subtle shift happening on factory floors and in filtration rooms. Buyers who once swore by plain weave are putting in repeat orders for Twill Weave Mesh. Honestly, the reason is simple: two-over-two weaving lets you use thicker wire at a given mesh count, so you get higher strength without blowing up pressure drop. In practice, that means steadier runs, fewer changeouts, and fewer headaches.

What it is (and why it matters)

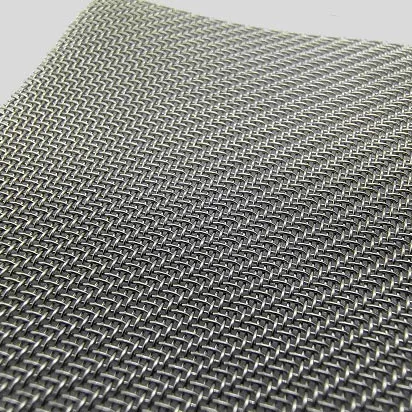

Stainless Steel Twill Weave Wire Mesh—also called stainless steel wire cloth, screen, or gauze—uses a diagonal pattern that distributes load better than plain weave. The payoffs: finer filtration (up to 635 mesh) with sturdier wires, cleaner edges after slitting, and improved dimensional stability under thermal cycling. Many customers tell me the mesh “settles in” nicely after first heat-up.

Quick technical snapshot

| Materials | SS 201, 304, 316, 316L (ASTM A580/A580M compliant) |

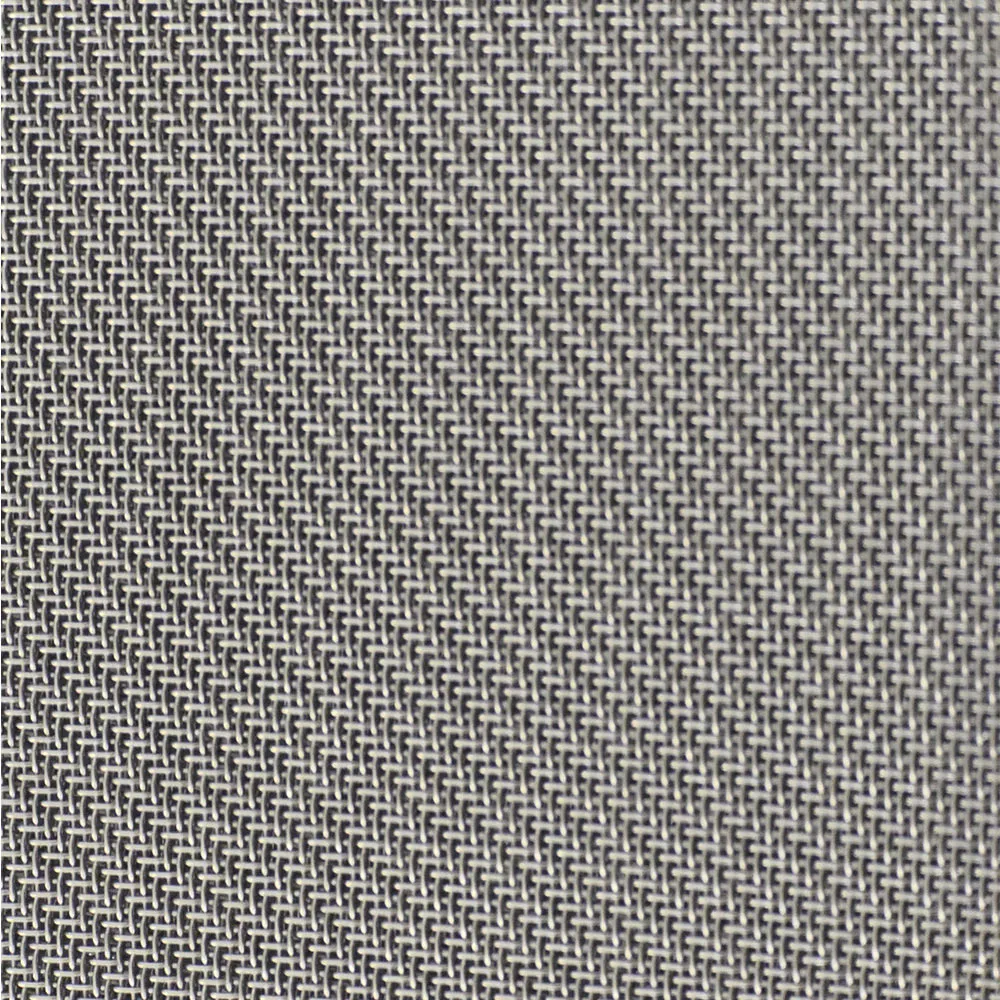

| Mesh range | 1–635 mesh (≈ 20,000–20 μm nominal aperture, real-world use may vary) |

| Wire diameter | 1.0–0.001 mm (caliper verified per ISO 9044) |

| Width | ≈0.915–2.0 m standard; custom widths available |

| Length | 30 m/roll typical; cut pieces, discs, and deep-processed parts on request |

| Other weaves | Plain, herringbone, Dutch, reverse Dutch |

Process flow and quality checkpoints

Origin matters: this mesh is produced in No.346 Xinying East Street, Anping County, Hebei, China—arguably the world’s wire cloth capital. The workflow, in brief:

- Materials: SS201/304/316/316L drawn wire (heat lot traceable), optional anneal for 316L.

- Weaving: shuttleless looms, twill pattern, tension control with in-line optical monitoring.

- Finishing: degreasing, optional calendering; edges slit to tolerance.

- Testing: aperture and wire dia per ISO 9044; mesh count per ASTM E2016; flatness and camber checks; salt-spray guidance for material selection (ASTM B117, indicative).

- Service life: ≈3–10 years in typical filtration; chemical media and cleaning cycles drive variance.

- Certifications/documents: mill test certificates, RoHS/REACH statements when requested, ISO 9001-managed processes (ask vendor for current certificate).

Sample test data (representative): 316L, 400 mesh twill, 0.025 mm wire—open area ≈30%, burst strength ≈1.5 kN/m, bubble point ≈12–14 kPa in water. Your results will vary with clamping and seam design.

Where Twill Weave Mesh shines

- Liquid and gas filtration: polymer melt filters, lube oil polishing, solvent recovery.

- Process screening: flour and spice sifting, battery slurry, ceramic powders.

- Chemical/petrochemical: catalyst support screens, demister components.

- Thermal/corrosive duty: 316/316L versions in chlorides or elevated temperature.

One buyer in packaging told me, “Switching to Twill Weave Mesh cut our blinding by half.” Take that as anecdotal—but not unusual.

Customization that actually helps

Beyond the standard 0.915–2.0 m widths, you can get laser-cut discs, pleated packs, spot-welded frames, and multi-layer sintered laminates. If you need tighter cutpoint control, pairing twill top layers with Dutch support is a smart move.

Vendor snapshot (what to look for)

| Vendor | Strengths | Notes |

|---|---|---|

| Ansheng Filter Screen (Anping, Hebei) | Deep catalog (1–635 mesh), custom widths, quick lead times | Origin at the source; MTC and ISO paperwork typically available |

| Local Fabricator B | Fast prototyping, small-batch conversions | May resell base mesh; costs ≈10–25% higher |

| Importer A | Commodity grades, aggressive pricing | Spec variability—audit per ASTM E2016/ISO 9044 |

Mini case files

Food & beverage: a brewery swapped 316 plain weave for 316L Twill Weave Mesh at 325 mesh. CIP times dropped ~12% and filter packs lasted an extra quarter.

Battery materials: a slurry line moved to 400 mesh twill with calendering; throughput rose ~8% thanks to more uniform aperture and fewer edge frays.

Final tip

If you’re speccing Twill Weave Mesh, call out material grade, mesh count, wire diameter, width/length, edge treatment, and the acceptance standards (ASTM E2016 and ISO 9044). Your process team will thank you.

Authoritative references

- ASTM E2016 – Standard Specification for Industrial Woven Wire Cloth. https://www.astm.org/e2016

- ISO 9044 – Industrial woven wire cloth – Technical requirements and tests. https://www.iso.org/standard/69045.html

- ASTM A580/A580M – Standard Specification for Stainless Steel Wire. https://www.astm.org/a0580_a0580m

Post time: Oct . 25, 2025 16:25