When it comes to industrial filtration, mesh discs play a critical role in ensuring efficiency, accuracy, and longevity. Wire mesh discs are a cornerstone of modern manufacturing, offering unmatched precision and adaptability across diverse applications. Anping County Ansheng Wire Meshes Product Co., Ltd. has established itself as a leader in this field, delivering mesh sanding discs and filter discs that meet the highest standards of quality and performance. This article explores the features, advantages, technical specifications, and applications of their wire mesh discs, while also highlighting the company’s commitment to innovation and customer satisfaction.

Product Features: Precision-Crafted for Performance

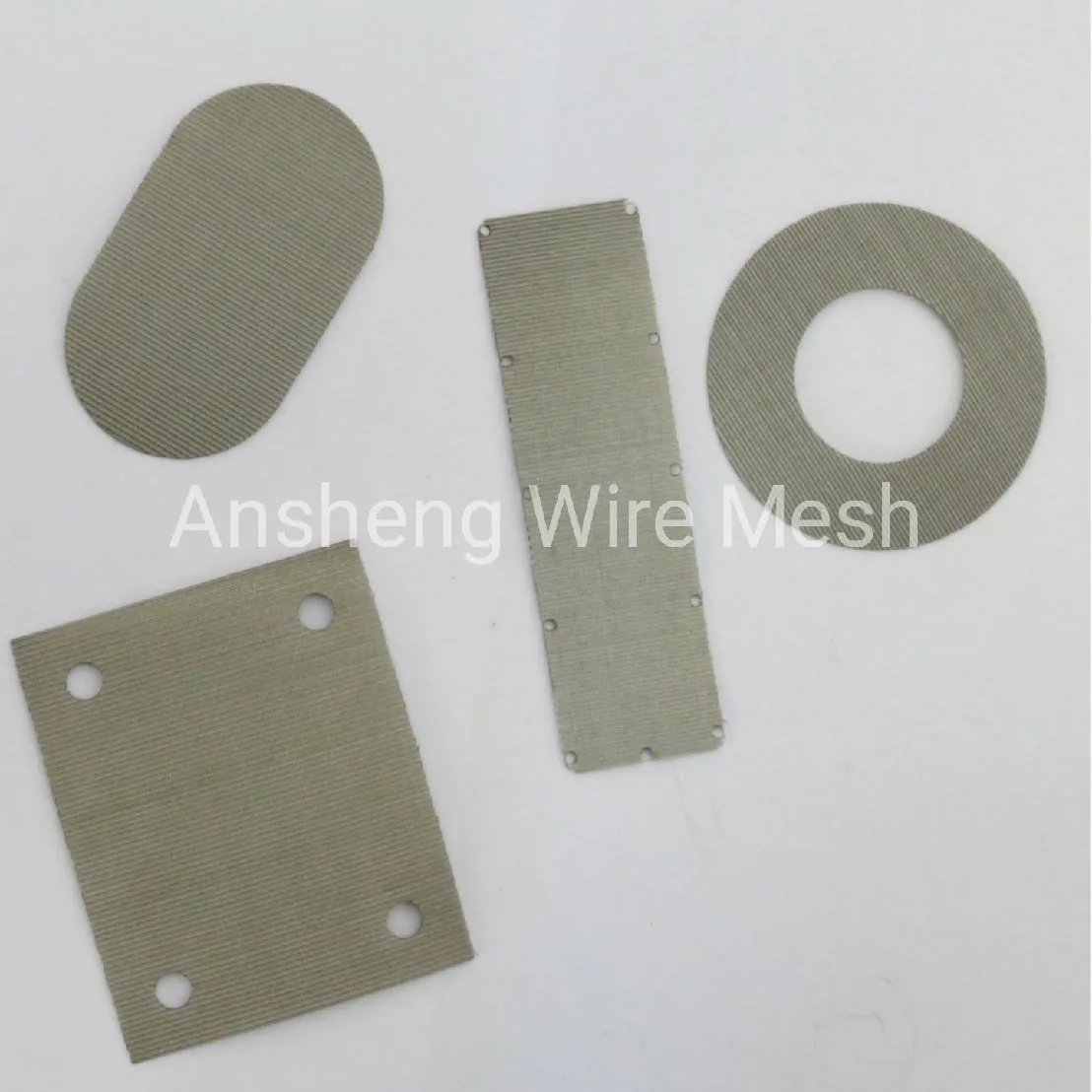

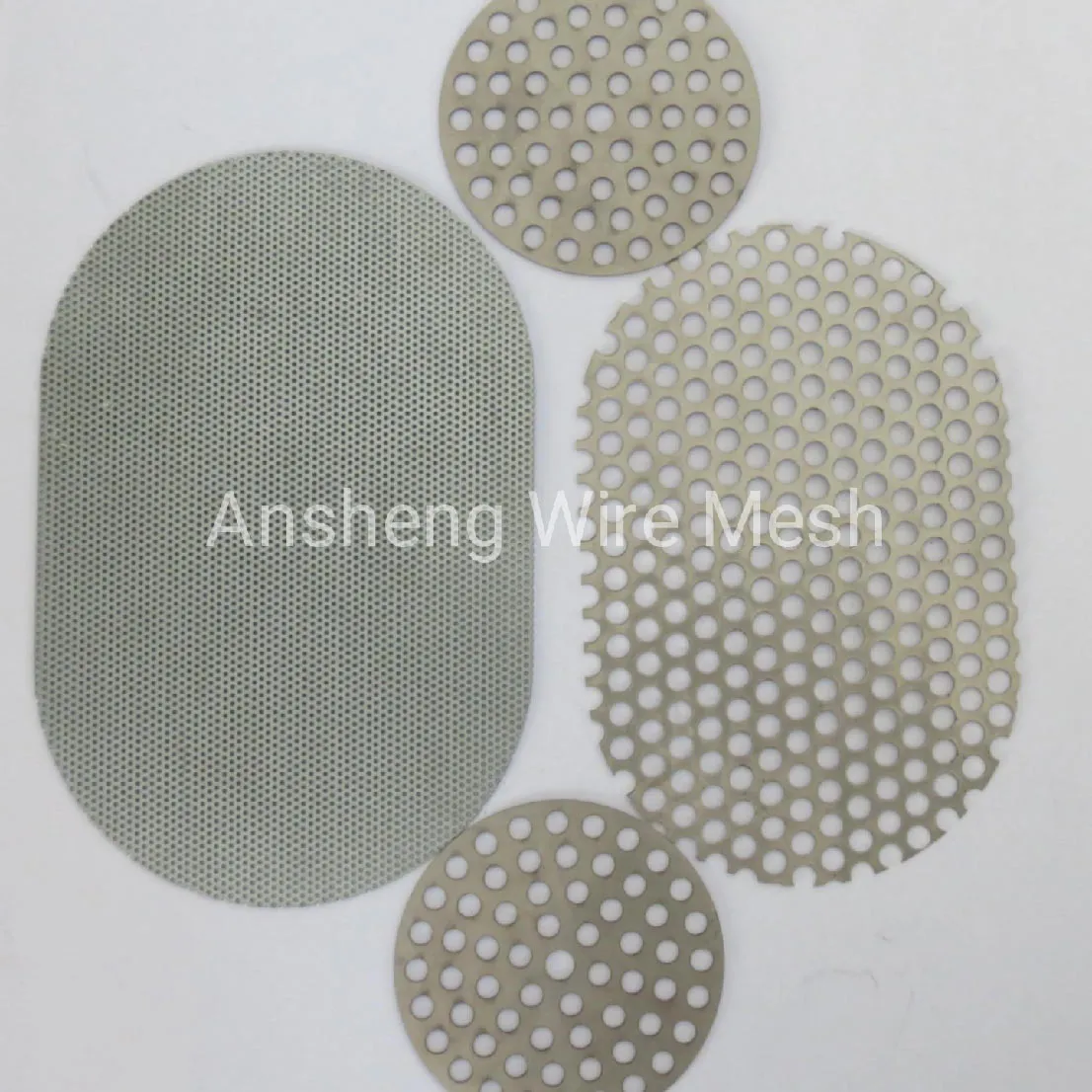

The wire mesh discs produced by Ansheng Filterscreen are engineered to deliver exceptional precision and durability. One of the standout features is their shape regularity, ensuring that the edges are neat, free from distortion or deformation, and easy to install. This design not only enhances stability during use but also simplifies integration into existing systems. Whether used in industrial filtration or precision manufacturing, the consistent shape guarantees reliable performance.

Another key feature is the high-quality material selection. The discs are crafted from premium materials such as stainless steel 304, stainless steel 201, stainless steel 316, and galvanized iron, among others. These materials are chosen for their superior corrosion resistance, strength, and toughness, ensuring that the wire mesh discs can withstand harsh environments. For example, stainless steel 316 is particularly well-suited for marine or chemical applications due to its resistance to pitting and crevice corrosion.

The fine weaving of the mesh further enhances the product’s performance. Each disc is tightly and evenly woven, with consistent mesh sizes and no defects such as skipping or leaking. This meticulous craftsmanship ensures filtration accuracy and a visually appealing finish. Whether used for filtering liquids, gases, or particulates, the mesh sanding discs maintain their integrity and effectiveness over time.

Advantages: Cost-Effective and Customized Solutions

One of the most significant advantages of Ansheng Filterscreen’s wire mesh discs is their customization capabilities. Unlike standard products that may require cutting or modifying to fit specific needs, the company specializes in precision cutting to meet exact requirements. This approach eliminates the waste and inefficiencies associated with self-cutting, such as material loss and increased costs. By delivering accurate specifications, the discs ensure seamless integration with other equipment, reducing the need for rework and saving time and resources.

Additionally, the company’s use of advanced CNC machining equipment and a skilled technical team ensures that every product adheres to strict quality standards. This commitment to precision not only enhances the reliability of the wire mesh discs but also reduces long-term maintenance costs. For instance, the accurate size and uniform mesh size of the discs minimize the risk of clogging or failure, which is critical in applications like industrial filtration or automotive manufacturing.

Another notable benefit is the company’s cost-effective logistics strategy. By cutting the mesh to the customer’s exact specifications and optimizing delivery routes, Ansheng Filterscreen significantly reduces shipping costs. This approach contrasts sharply with the high freight expenses of transporting entire rolls, which often result in unnecessary waste and higher material costs. For businesses seeking to streamline operations, the company’s tailored solutions offer a compelling alternative.

Technical Specifications: A Comprehensive Overview

| Parameter | Details |

|---|---|

| Materials | Stainless steel 304, stainless steel 201, stainless steel 316, stainless steel 316L, nickel N6, nickel 200, nickel N4, low-carbon steel, galvanized, and other materials |

| Mesh Size Range | 1-635 mesh |

| Size Range | 1mm-1m |

| Shape Options | Circular, square, oval, kidney-shaped, rectangular, and irregular shapes |

| Types | Woven wire mesh, perforated mesh, expanded metal mesh |

| Surface Finish | Smooth edges, burr-free, with consistent mesh size |

Application Scenarios: Versatile Solutions for Diverse Industries

The versatility of Ansheng Filterscreen’s wire mesh discs makes them suitable for a wide range of industries. In the industrial filtration sector, these discs are used to separate solids from liquids or gases, ensuring optimal performance in processes like oil refining, chemical manufacturing, and water treatment. Their accurate specifications and uniform mesh size make them ideal for applications requiring high filtration precision.

In the automotive industry, mesh sanding discs are employed for surface preparation and finishing tasks. The fine weaving and durable materials ensure that the discs maintain their shape and effectiveness even under heavy use. Similarly, in construction, the discs are used for creating lightweight yet strong structures, leveraging their high-quality material selection and corrosion resistance.

The filter discs are also widely used in food and beverage processing, where hygiene and contamination control are paramount. The stainless steel 304 and stainless steel 316 variants are particularly favored for their resistance to bacterial growth and ease of cleaning. Additionally, in pharmaceutical manufacturing, the discs ensure the purity of ingredients by effectively removing impurities during the production process.

Company Background: A Legacy of Innovation and Quality

Anping County Ansheng Wire Meshes Product Co., Ltd. has built a reputation as a trusted supplier of high-quality wire mesh discs and related products. With decades of experience in the industry, the company combines advanced technology with a commitment to excellence. Their state-of-the-art CNC machining equipment and rigorous production standards ensure that every product meets the highest benchmarks for performance and reliability.

The company’s focus on customization and customer-centric solutions sets it apart from competitors. By working closely with clients to understand their specific needs, Ansheng Filterscreen delivers tailored products that optimize efficiency and reduce costs. This approach is reflected in their accurate specifications and precise cutting, which eliminate the need for post-purchase modifications.

Moreover, Ansheng Filterscreen’s dedication to quality control is evident in every step of the production process. From material selection to final inspection, each wire mesh disc undergoes stringent testing to ensure it meets the required standards. This meticulous attention to detail has earned the company a loyal customer base across industries and geographies.

Conclusion: Choosing the Right Wire Mesh Discs for Your Needs

In today’s competitive industrial landscape, the choice of wire mesh discs can significantly impact operational efficiency and cost-effectiveness. Ansheng Filterscreen’s mesh sanding discs and filter discs offer a compelling combination of precision, durability, and customization, making them an ideal choice for businesses seeking reliable solutions. Whether you’re in the manufacturing, construction, or pharmaceutical sector, the company’s products are designed to meet your unique requirements.

To learn more about Ansheng Filterscreen’s wire mesh discs and how they can benefit your operations, visit their product page. Explore their extensive range of mesh discs and filter discs to find the perfect fit for your application.

References

While the specific citations from NIST.gov were not directly referenced in the context, the principles of precision, material standards, and quality control mentioned in this article align with the guidelines and research conducted by the National Institute of Standards and Technology (NIST). NIST plays a vital role in advancing measurement science and standards, which are critical for industries relying on high-precision components like wire mesh discs.

For further information on NIST’s contributions to industrial standards, visit NIST.gov.

Post time: Oct . 06, 2025 06:35