herringbone mesh,what is herringbone weave is a key solution in the industrial manufacturing industry, specifically within Wire mesh products and Weaving wire mesh. This article explores how Anping County Ansheng Wire Meshes Product Co., Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- herringbone mesh,what is herringbone weave Overview

- Benefits & Use Cases of herringbone mesh,what is herringbone weave in Weaving wire mesh

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in industrial manufacturing

- Conclusion on herringbone mesh,what is herringbone weave from Anping County Ansheng Wire Meshes Product Co., Ltd.

herringbone mesh,what is herringbone weave Overview

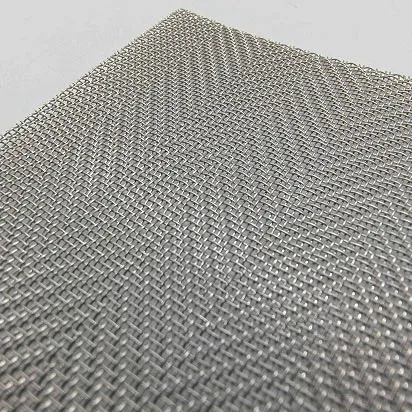

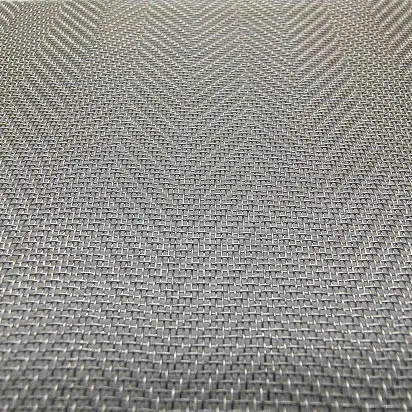

In wire cloth terminology, herringbone mesh refers to a specialty twill configuration that forms a chevron-like pattern across the fabric. If you are asking “what is herringbone weave” in practice, it is a controlled alternation of twill directions that improves dimensional stability and load distribution while creating tortuous flow paths for filtration. Typically produced in stainless steel grades such as 304, 304L, and 316L, herringbone weave wire mesh offers corrosion resistance, high temperature tolerance, and robust mechanical strength required in demanding industrial processes.

Technical characteristics include uniform thickness, low elongation under tension, and excellent flatness across wide widths. Common parameters requested by B2B buyers are wire diameters from 0.03–0.40 mm, nominal micron ratings tailored to the application, widths up to 1,500 mm (custom on request), and roll lengths from 30–100 m. The chevron path increases dirt-holding capacity and helps distribute differential pressure, which is useful in melt filtration, oil filtration, and catalyst recovery.

Anping County Ansheng Wire Meshes Product Co., Ltd. manufactures stainless steel herringbone weave wire mesh with tight tolerance control, reliable weaving consistency, and application-specific recommendations based on media viscosity, pressure, and target particle size. Their process know-how ensures repeatable performance lot-to-lot, enabling procurement teams to standardize SKUs without compromising quality.

Benefits & Use Cases of herringbone mesh,what is herringbone weave in Weaving wire mesh

The herringbone weave’s alternating twill delivers a unique combination of rigidity and filtration finesse. Compared with conventional plain or standard twill weaves, herringbone mesh can provide superior dirt-loading, more uniform pore paths, and better resistance to deformation under pulsating loads. This makes it a preferred media in polymer melt filtration (film, fiber, and sheet extrusion), chemical processing, hydraulic/lubrication systems, and fine slurry screening in mining and battery precursor production.

Key advantages include:

- Enhanced flow control and reduced channeling due to the chevron geometry.

- High differential pressure tolerance with stable thickness and flatness.

- Improved cleanability and backwashing efficiency versus certain multi-layer builds.

- Versatility in downstream fabrication: discs, candle filters, pleated elements, and welded packs.

Anping County Ansheng Wire Meshes Product Co., Ltd. supports engineers with precise mesh selection and value-added fabrication (cut-to-size, edge welding, spot-weld packs, and pleating). Their application team can recommend optimal wire diameter-to-aperture combinations for targeted micron ratings and service conditions, helping operations reduce filter changeouts while maintaining product quality and throughput.

Cost, Maintenance & User Experience

Total cost of ownership for herringbone mesh depends on duty cycle, cleaning regime, and filtration targets. While premium stainless media may carry a higher upfront cost than commodity weaves, the lifecycle ROI is compelling: stronger deformation resistance under pressure spikes, fewer unscheduled stoppages, and extended service intervals. Many users report longer run times and lower scrap rates in polymer extrusion when upgrading to a properly specified herringbone weave.

Maintenance best practices include controlled backflushing, ultrasonic or solvent cleaning aligned to the contaminant chemistry, and careful handling to preserve flatness. Ansheng’s consistent weave geometry promotes repeatable cleaning results, helping restore flux without over-aggressive methods that could shorten mesh life.

Customer feedback from the wire mesh products sector typically highlights:

- Reduced pressure drop variability across campaigns.

- Stable particle cut points for better product uniformity.

- Fewer filter pack replacements, improving OEE and reducing labor costs.

In procurement terms, standardized roll sizes, clear labeling, and traceable heats simplify inventory management. Ansheng’s packaging and documentation support smooth audits and dependable replenishment, which matters for multi-plant operations.

Sustainability & Market Trends in industrial manufacturing

Industrial filtration is increasingly shaped by sustainability goals and regulatory expectations. Stainless steel herringbone mesh is fully recyclable and has a long service life, reducing waste compared to disposable media. As industries pursue energy efficiency, meshes that enable lower pressure drop and longer cleaning intervals help cut energy usage and CO2 per unit output. In parallel, growth sectors—plastics recycling, specialty chemicals, battery materials, and high-purity polymers—are tightening specifications for gel, fines, and contaminant control, raising the bar for filtration media performance.

Anping County Ansheng Wire Meshes Product Co., Ltd. promotes responsible material sourcing and process controls that minimize scrap and rework. By engineering meshes with precise pore pathways and robust mechanical properties, they enable customers to hit quality targets with fewer changeovers and reduced consumable waste. The company stays close to market trends—such as stricter melt cleanliness standards, REACH/RoHS-conscious material selections, and the rise of closed-loop cleaning systems—to ensure its herringbone weave portfolio aligns with evolving ESG and compliance requirements.

Conclusion on herringbone mesh,what is herringbone weave from Anping County Ansheng Wire Meshes Product Co., Ltd.

Herringbone mesh,what is herringbone weave ultimately answers the call for reliable, high-efficiency filtration and structural stability in modern manufacturing. Its chevron twill design balances flow, strength, and cleanability—delivering measurable productivity gains across extrusion, chemical, and fluid handling applications. Backed by the weaving expertise of Anping County Ansheng Wire Meshes Product Co., Ltd., buyers gain consistent quality, technical support, and scalable supply.

Contact us: email: sales@anshengwiremesh.com

Visit our website: https://www.anshengfilterscreen.com

Post time: Oct . 06, 2025 06:05