When it comes to wire mesh discs, precision, durability, and cost-efficiency are non-negotiable. Anping County Ansheng Wire Meshes Product Co., Ltd. has established itself as a leader in providing high-quality mesh sanding discs and filtration solutions tailored to diverse industrial needs. This article delves into the features, advantages, technical specifications, and applications of their single-layer wire mesh discs, while highlighting the company’s commitment to innovation and customer satisfaction.

Product Features: Precision and Durability Redefined

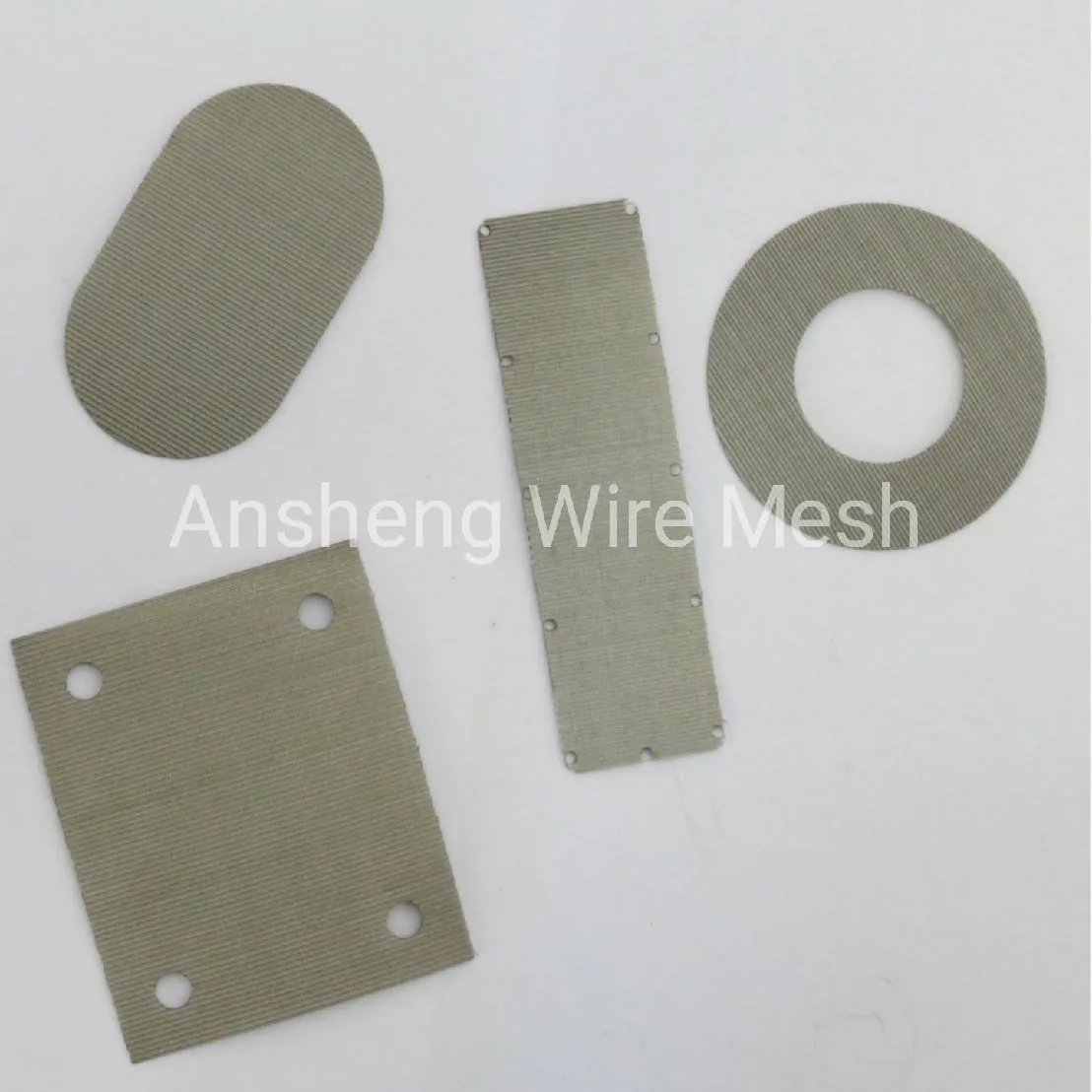

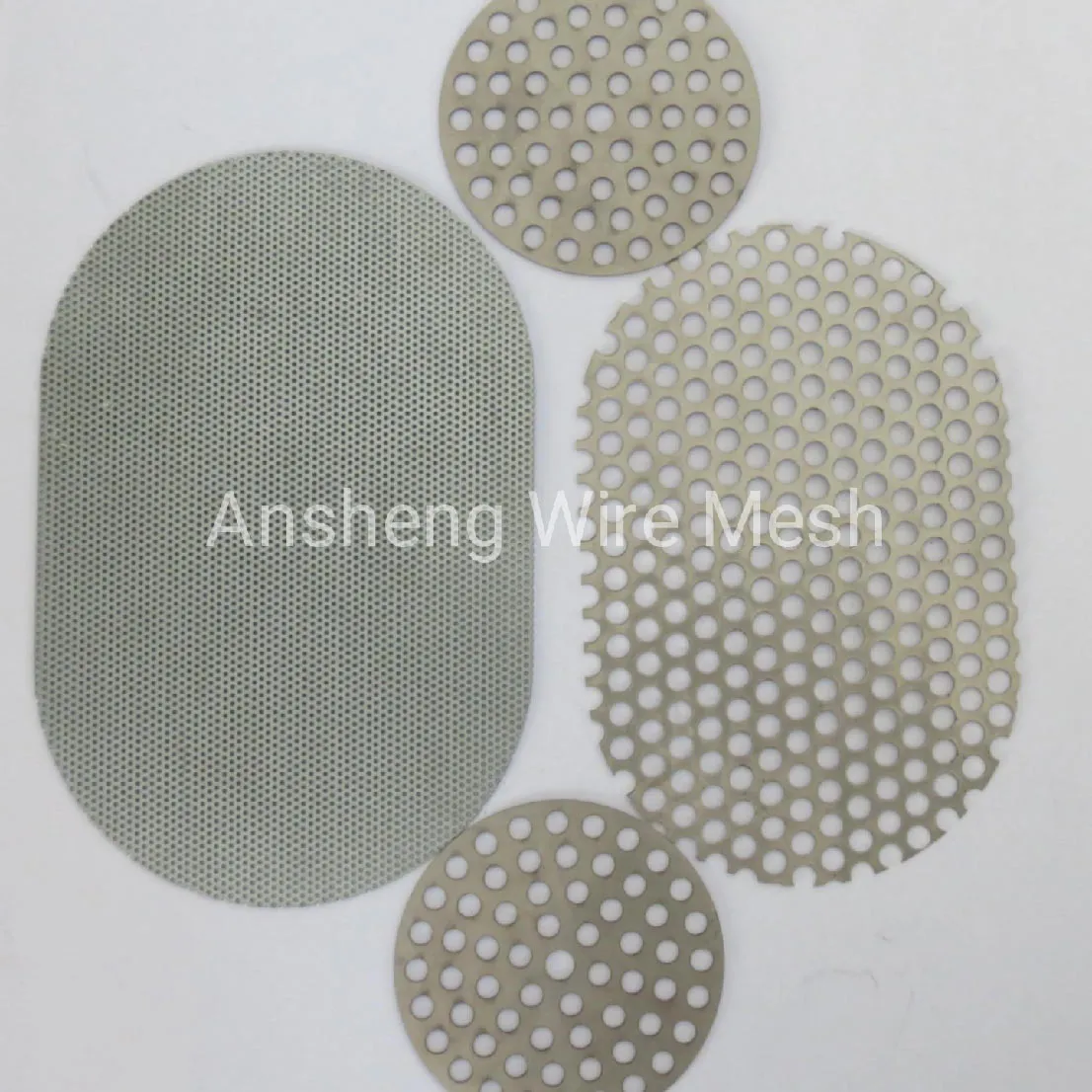

The wire mesh discs from Ansheng Filterscreen are engineered to meet the highest standards of quality and performance. One of their standout features is the shape regularity, ensuring that the edges of the mesh are neat, free from distortion, and easy to install. This design not only enhances stability during use but also reduces the risk of damage during handling.

Another critical aspect is the high-quality material selection. Ansheng Filterscreen uses premium raw materials such as high-grade stainless steel (304, 201, 316, 316L), nickel alloys (N6, Nickel 200, N4), low-carbon steel, and galvanized metals. These materials are chosen for their exceptional corrosion resistance, strength, and toughness, ensuring the mesh can withstand harsh environments and prolonged use.

The fine weaving of the mesh is another hallmark of Ansheng’s craftsmanship. The mesh is tightly and evenly woven, with consistent mesh sizes and no defects like skipping or leakage. This precision guarantees filtration accuracy and a visually appealing finish, making it ideal for applications where aesthetics and functionality are equally important.

Additionally, the accurate specifications of the mesh ensure that dimensions such as length, width, and aperture align with design requirements. Deviations are strictly controlled within allowable ranges, allowing seamless integration with other equipment and components.

Advantages: Cost-Effective and Efficient Solutions

One of the primary advantages of Ansheng Filterscreen’s mesh sanding discs is their customization capabilities. The company utilizes advanced CNC machining equipment and an experienced technical team to produce mesh discs tailored to specific customer requirements. This precision ensures that every product meets exacting standards, eliminating the need for rework and reducing project costs.

Traditional methods of purchasing entire rolls of mesh and cutting them in-house often result in significant material waste and increased costs. Ansheng’s direct customization service addresses this issue by minimizing waste through high-precision cutting. The company also optimizes logistics to deliver products according to actual needs, significantly reducing shipping expenses.

Furthermore, Ansheng Filterscreen’s commitment to efficient production processes ensures that customers benefit from faster turnaround times and reduced project delays. This approach not only saves time but also enhances overall project efficiency, making it a preferred choice for industries where time is a critical factor.

Technical Specifications: A Comprehensive Overview

Ansheng Filterscreen’s wire mesh discs are available in a wide range of materials, sizes, and shapes to suit various applications. Below is a detailed table summarizing the technical specifications:

| Category | Details |

|---|---|

| Materials | Stainless steel 304, 316, 316L; nickel alloys (N6, Nickel 200, N4); low-carbon steel; galvanized; and other custom materials. |

| Mesh Size Range | 1 to 635 mesh. |

| Dimension Range | 1 mm to 1 meter. |

| Shapes | Circular, square, oval, kidney-shaped, rectangular, and irregular shapes. |

| Types | Woven wire mesh, perforated mesh, and expanded metal mesh. |

| Surface Finish | Smooth edges, burr-free, and uniform mesh size. |

The combination of these specifications ensures that Ansheng’s products can be adapted to a wide array of industrial applications, from filtration systems to sanding tools.

Application Scenarios: Versatility in Action

The wire mesh discs from Ansheng Filterscreen are designed for use in multiple industries. Their versatility makes them a preferred choice for:

- Filtration Systems: The precise mesh size and uniform structure make these discs ideal for filtering liquids and gases in chemical processing, food and beverage production, and pharmaceuticals.

- Sanding and Polishing: The mesh sanding discs are used in industrial sanding applications, offering durability and consistent performance.

- Industrial Equipment: The accurate specifications and robust construction allow these discs to integrate seamlessly into machinery and equipment, ensuring long-term reliability.

- Custom Manufacturing: Ansheng’s ability to produce non-standard shapes and sizes makes their products suitable for specialized manufacturing processes.

Company Background: Ansheng Filterscreen’s Commitment to Excellence

Anping County Ansheng Wire Meshes Product Co., Ltd. is a leading manufacturer of wire mesh products, with a focus on innovation, quality, and customer-centric solutions. Located in Anping County, Hebei Province, the company has built a reputation for delivering high-performance products that meet global standards.

With over a decade of experience in the industry, Ansheng Filterscreen has invested heavily in advanced manufacturing technologies, including CNC machining and automated testing systems. This commitment to technological advancement ensures that every product undergoes rigorous quality checks, guaranteeing consistency and reliability.

The company’s experienced technical team plays a pivotal role in developing custom solutions for clients. By combining technical expertise with a deep understanding of industry requirements, Ansheng Filterscreen consistently exceeds customer expectations.

Moreover, Ansheng Filterscreen’s emphasis on environmental responsibility and logistical efficiency further enhances its appeal. The company’s streamlined production and delivery processes minimize waste and reduce costs, making their products an attractive option for businesses seeking sustainable and cost-effective solutions.

Conclusion: Why Choose Ansheng Filterscreen?

Ansheng Filterscreen’s wire mesh discs stand out in the market due to their exceptional quality, customization options, and cost-effectiveness. Whether you’re looking for filtration solutions, sanding tools, or industrial components, Ansheng’s products are designed to deliver precision and durability.

By choosing Ansheng Filterscreen, customers gain access to a partner that prioritizes innovation, quality, and customer satisfaction. With a proven track record of excellence and a commitment to meeting the evolving needs of industries worldwide, Ansheng Filterscreen is a trusted name in the wire mesh manufacturing sector.

References

1. National Institute of Standards and Technology (NIST). NIST plays a critical role in advancing technology through research and standardization. Their work in precision measurements and material science aligns with the standards upheld by Ansheng Filterscreen.

2. Ansheng Filterscreen Official Website. For more information on products, specifications, and customization options.

Post time: Sep . 29, 2025 08:25