Twill weave wire mesh is a key solution in the manufacturing industry, specifically within Fabricated metal products and Manufacturing of metal wire ropes and their products. This article explores how Anping County Ansheng Wire Meshes Product Co., Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Twill Weave Wire Mesh Overview

- Benefits & Use Cases of Twill Weave Wire Mesh in Manufacturing of metal wire ropes and their products

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on Twill Weave Wire Mesh from Anping County Ansheng Wire Meshes Product Co., Ltd.

Twill Weave Wire Mesh Overview

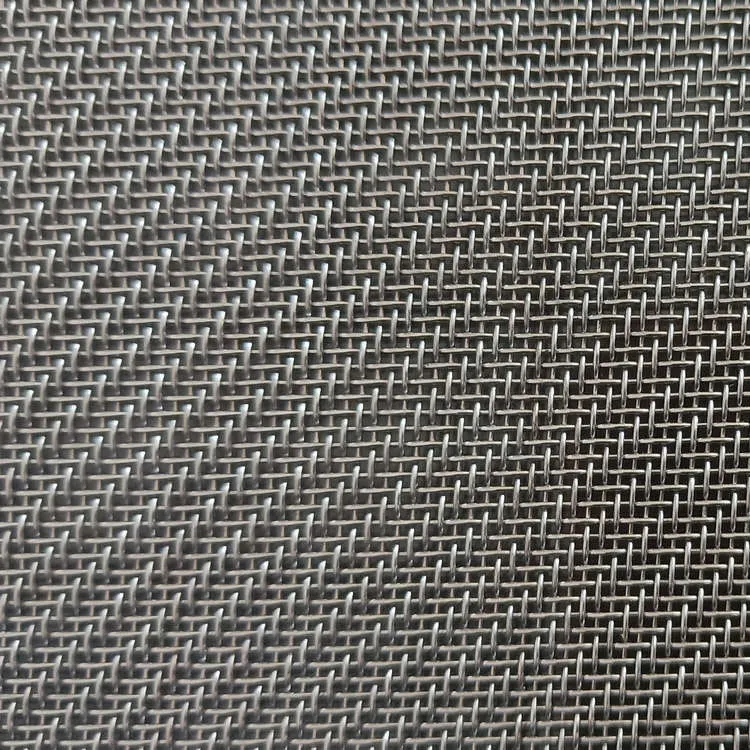

In the demanding world of manufacturing, particularly within Fabricated metal products and the intricate Manufacturing of metal wire ropes and their products, the choice of materials can significantly impact operational efficiency and product quality. Twill weave wire mesh stands out as a superior filtration and separation medium. Unlike plain weave mesh, twill weave wire mesh features a distinct pattern where each warp wire passes alternately over two weft wires and then under two weft wires. This over-two, under-two pattern allows for a much thicker wire diameter relative to the aperture size, resulting in a robust, stable, and highly durable mesh with finer filtration capabilities.

Its unique structure provides exceptional strength and the ability to hold heavier loads, making it ideal for high-pressure filtration and applications requiring increased resistance to wear and tear. Common materials include various grades of stainless steel, such as 304, 304L, 316, and 316L, chosen for their corrosion resistance, temperature stability, and hygienic properties. Anping County Ansheng Wire Meshes Product Co., Ltd. specializes in manufacturing high-precision twill weave mesh, offering a range of specifications tailored to meet the exacting standards of industrial clients, ensuring reliability and performance in critical manufacturing processes.

Benefits & Use Cases of Twill Weave Wire Mesh in Manufacturing of metal wire ropes and their products

For B2B decision-makers in the Manufacturing of metal wire ropes and their products sector, the advantages of integrating twill weave wire mesh are multifaceted. Its superior strength and rigidity make it highly suitable for applications involving high-pressure environments and significant mechanical stress. In the production of wire ropes, for instance, twill weave mesh can be utilized in various stages, from filtering lubricants and coolants to separating fine particles from raw materials, ensuring the purity and integrity of the final product. The ability of twill weave mesh to achieve very fine filtration while maintaining structural integrity is a critical competitive advantage.

Anping County Ansheng Wire Meshes Product Co., Ltd.'s expertise in this field ensures that our twill weave wire mesh products offer consistent pore size, exceptional particle retention, and a longer service life compared to alternative filtration media. This translates directly into reduced maintenance downtime, improved product consistency, and enhanced operational safety. Whether it's for hydraulic filter elements, sieves, or protective screens, the robust construction of our twill mesh solutions provides a reliable barrier against contaminants and contributes to the overall longevity and performance of industrial machinery, underpinning the quality of fabricated metal products.

Cost, Maintenance & User Experience

Investing in high-quality twill weave wire mesh from Anping County Ansheng Wire Meshes Product Co., Ltd. offers a compelling total cost of ownership (TCO) proposition for businesses in the Fabricated metal products sector. While the initial investment for a superior-grade twill mesh might be slightly higher than standard alternatives, the long-term savings are substantial. The exceptional durability and resistance to abrasion, corrosion, and high temperatures inherent in our stainless steel twill weave mesh significantly reduce the frequency of replacements and maintenance. This translates into less operational downtime, lower labor costs associated with change-outs, and a more consistent production flow, all contributing to a strong return on investment (ROI).

Customers consistently report high satisfaction with the longevity and reliable performance of our twill weave wire mesh in their most demanding applications. Feedback from the Fabricated metal products sector highlights the mesh's ability to maintain structural integrity and filtration efficiency even under continuous stress. This reliability minimizes unexpected failures and ensures uninterrupted processing, directly enhancing the user experience for engineers and operators. Our commitment to quality ensures that each twill mesh product is engineered for maximum performance and minimal upkeep, providing peace of mind and operational excellence.

Sustainability & Market Trends in manufacturing

As the manufacturing landscape continues to evolve, sustainability and adherence to stringent regulations have become paramount. Anping County Ansheng Wire Meshes Product Co., Ltd. is committed to forward-thinking practices, and our twill weave wire mesh solutions align perfectly with these market trends. The extended lifespan of our high-quality stainless steel twill mesh significantly reduces material waste and the environmental impact associated with frequent replacements. Furthermore, stainless steel itself is a highly recyclable material, contributing to a circular economy model within the manufacturing sector.

Beyond environmental benefits, the precision filtration offered by twill weave wire mesh can lead to more efficient use of resources and energy in various industrial processes. Cleaner separation and finer filtration mean less product loss and optimized system performance. The market trend towards higher purity standards and increased regulatory scrutiny in industries like food processing, pharmaceuticals, and precision engineering further solidifies the need for reliable filtration solutions. Anping County Ansheng Wire Meshes Product Co., Ltd. positions itself as an eco-conscious and innovation-driven partner, providing twill weave wire mesh products that not only meet but exceed evolving industry standards for performance, safety, and sustainability.

Conclusion on Twill Weave Wire Mesh from Anping County Ansheng Wire Meshes Product Co., Ltd.

In conclusion, for B2B decision-makers in manufacturing, particularly within Fabricated metal products and the Manufacturing of metal wire ropes and their products, twill weave wire mesh is an indispensable component. Its superior strength, fine filtration capabilities, and exceptional durability ensure improved operational efficiency, reduced maintenance costs, and enhanced product quality. Anping County Ansheng Wire Meshes Product Co., Ltd. stands as a trusted leader in providing premium twill weave mesh solutions, engineered with precision and built to withstand the most challenging industrial environments. Our commitment to quality, customer satisfaction, and sustainable practices makes us the ideal partner for your business needs.

Elevate your manufacturing processes with the reliability and performance of our twill weave wire mesh. Contact us today to discuss your specific requirements and discover how our expertise can benefit your operations.

- Contact us: email: sales@anshengwiremesh.com

- Visit our website: https://www.anshengfilterscreen.com

Post time: Sep . 29, 2025 08:45