When it comes to industrial filtration, material separation, and precision engineering, **wire mesh discs** stand out as a critical component. These discs, crafted with meticulous attention to detail, offer a blend of durability, accuracy, and versatility that meets the demands of modern manufacturing. This article delves into the **single-layer wire mesh discs** from **Anping County Ansheng Wire Meshes Product Co., Ltd.**, exploring their features, advantages, technical specifications, and real-world applications.

Product Overview and Core Features

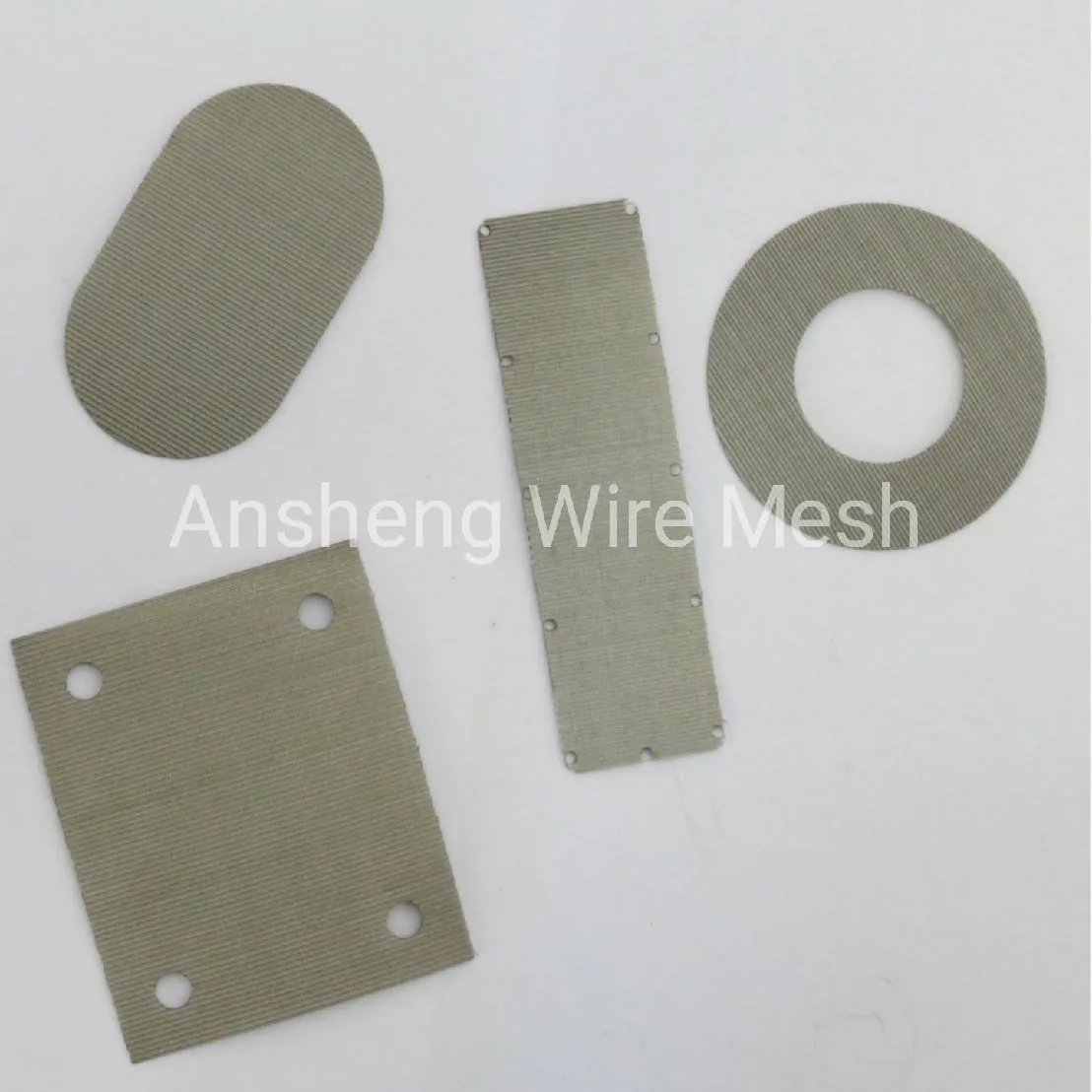

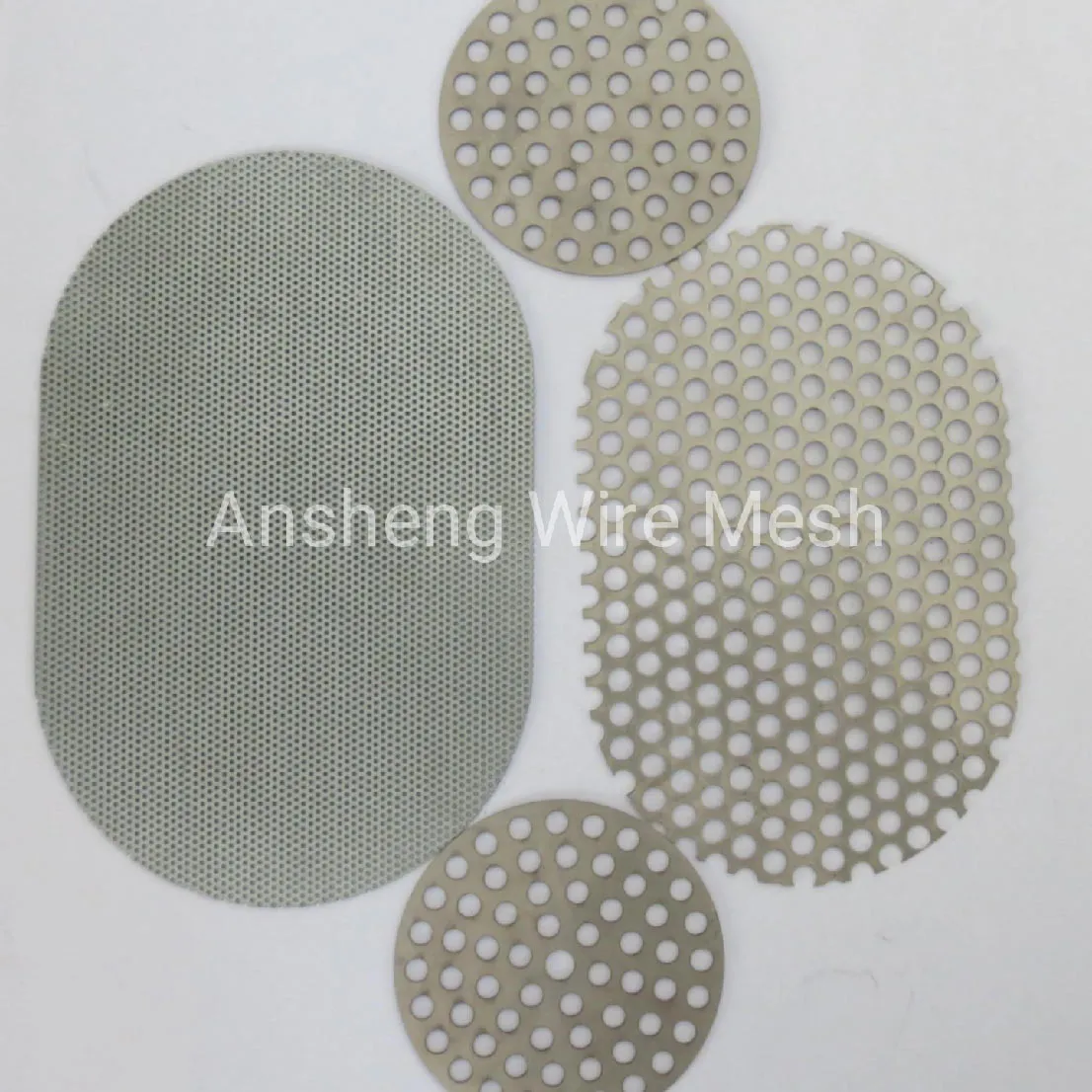

The **wire mesh disc** is a precision-engineered component designed for applications requiring accurate filtration, separation, or structural support. The product’s design emphasizes **shape regularity**, **high-quality material selection**, and **fine weaving**, ensuring optimal performance in diverse environments.

Shape Regularity and Structural Integrity

One of the standout features of the **wire mesh disc** is its **shape regularity**. The edges are meticulously crafted to be neat and free from distortion or deformation, ensuring a uniform shape. This precision not only simplifies installation but also enhances the disc’s stability during operation. Whether used in industrial filtration systems or as a structural component, the disc’s consistent geometry ensures seamless integration with other equipment.

High-Quality Material Selection

The **wire mesh disc** is manufactured using **high-purity and high-quality raw materials**, including stainless steel grades such as 304, 201, 316, and 316L, as well as galvanized iron. These materials are chosen for their **corrosion resistance**, **strength**, and **toughness**, making the discs suitable for harsh environments. For instance, **stainless steel 316** is ideal for marine or chemical applications, while **galvanized iron** offers cost-effective durability in general industrial settings.

Fine Weaving and Filtration Accuracy

The **wire mesh disc** is **finely woven** to ensure a uniform mesh size and eliminate defects like skipping or leakage. This precision guarantees **filtration accuracy**, which is critical in applications such as **mesh sanding discs** or **filter discs**. The tight weave also contributes to the disc’s aesthetic appeal, making it a preferred choice for both functional and decorative purposes.

Technical Specifications and Customization Capabilities

The **wire mesh disc** is available in a wide range of specifications to suit diverse industrial needs. The following table provides a detailed overview of the product’s technical parameters:

| Parameter | Details |

|---|---|

| Materials | Stainless steel 304, 201, 316, 316L, nickel N6, nickel 200, nickel N4, low-carbon steel, galvanized, etc. |

| Mesh Size Range | 1-635 mesh |

| Dimensions | 1mm-1m |

| Shapes | Circle, square, oval, kidney-shaped, rectangle, and irregular shapes |

| Types | Woven wire mesh, perforated mesh, expanded metal mesh |

Customization is a key strength of the **wire mesh disc**. The company employs **advanced CNC machining equipment** and a team of experienced engineers to produce discs tailored to specific requirements. This includes precise **accurate specifications**, such as controlled deviations in length, width, and aperture, ensuring seamless integration into existing systems.

Advantages and Cost-Effective Solutions

Choosing **Anping County Ansheng Wire Meshes Product Co., Ltd.** for **wire mesh discs** offers several advantages. One of the most significant is the **custom cutting service**, which eliminates the need for customers to purchase and cut entire rolls of mesh. This not only reduces **waste** but also lowers **material costs** and **shipping expenses**. According to the company, their high-precision cutting process ensures **no material waste**, while their logistics planning further optimizes costs.

Moreover, the **strict production standards** and **testing processes** guarantee that every **wire mesh disc** meets the highest quality benchmarks. This reduces the risk of rework and ensures **installation efficiency**, saving time and resources for customers.

Applications Across Industries

The versatility of the **wire mesh disc** makes it suitable for a wide range of applications. Some key areas include:

- Filtration Systems: The disc’s precise mesh size and durability make it ideal for **filter discs** in water treatment, chemical processing, and food and beverage industries.

- Industrial Sieving: The **mesh sanding discs** are used in grinding and polishing applications, where consistent mesh size ensures even material removal.

- Structural Components: The disc’s strength and shape regularity allow it to serve as a support or reinforcement element in machinery and equipment.

- Architectural and Decorative Uses: The aesthetic appeal of the **wire mesh disc** makes it a popular choice for design elements in public spaces, such as lighting fixtures and wall panels.

Company Background and Commitment to Quality

**Anping County Ansheng Wire Meshes Product Co., Ltd.** is a leading manufacturer specializing in **wire mesh discs** and related products. With years of experience in the industry, the company has established itself as a trusted partner for businesses requiring precision-engineered solutions. Their commitment to **quality control** is evident in their use of advanced technology, rigorous testing protocols, and customer-centric approaches.

The company’s ability to deliver **customized solutions** sets it apart from competitors. By leveraging **advanced CNC machining equipment** and a skilled technical team, they ensure that every product meets the unique needs of their clients. This dedication to innovation and excellence has earned them a reputation for reliability and performance.

Ensuring Accuracy and Compliance with Industry Standards

The importance of **accurate specifications** cannot be overstated, particularly in industrial applications where even minor deviations can lead to operational inefficiencies. According to the **National Institute of Standards and Technology (NIST)**, "Precise measurements are essential for ensuring the reliability and consistency of industrial components" (NIST, 2025). The **wire mesh discs** from Anping County Ansheng Wire Meshes Product Co., Ltd. are designed to meet these exacting standards, with deviations controlled within acceptable limits.

This adherence to **industry standards** ensures that the discs perform reliably in critical applications. Whether used in **filter systems** or **structural components**, the discs provide a level of precision that aligns with the benchmarks set by organizations like NIST.

Conclusion

The **wire mesh disc** from **Anping County Ansheng Wire Meshes Product Co., Ltd.** is a testament to the power of precision engineering and quality craftsmanship. With its **shape regularity**, **high-quality materials**, and **customization capabilities**, the product offers a versatile solution for industries ranging from manufacturing to architecture. By prioritizing **accurate specifications** and **cost-effective production**, the company ensures that customers receive a product that not only meets but exceeds expectations.

As the demand for precision components continues to grow, **Anping County Ansheng Wire Meshes Product Co., Ltd.** remains at the forefront of innovation, delivering **wire mesh discs** that combine performance, reliability, and value.

References

National Institute of Standards and Technology (NIST). (2025). Driving Innovation. Retrieved from https://www.nist.gov/

Post time: Jul . 31, 2025 23:20