At Anping County Ansheng Wire Meshes Product Co., Ltd., we specialize in manufacturing Single Layer Wire Mesh Discs that combine advanced engineering with high-quality materials to meet the demands of diverse industrial applications. These discs are designed to deliver exceptional performance, precision, and reliability, making them a preferred choice for filtration, screening, and industrial processing. In this article, we will explore the key features, technical specifications, and benefits of our Single Layer Wire Mesh Discs, as well as the company’s commitment to innovation and customer satisfaction.

Product Overview

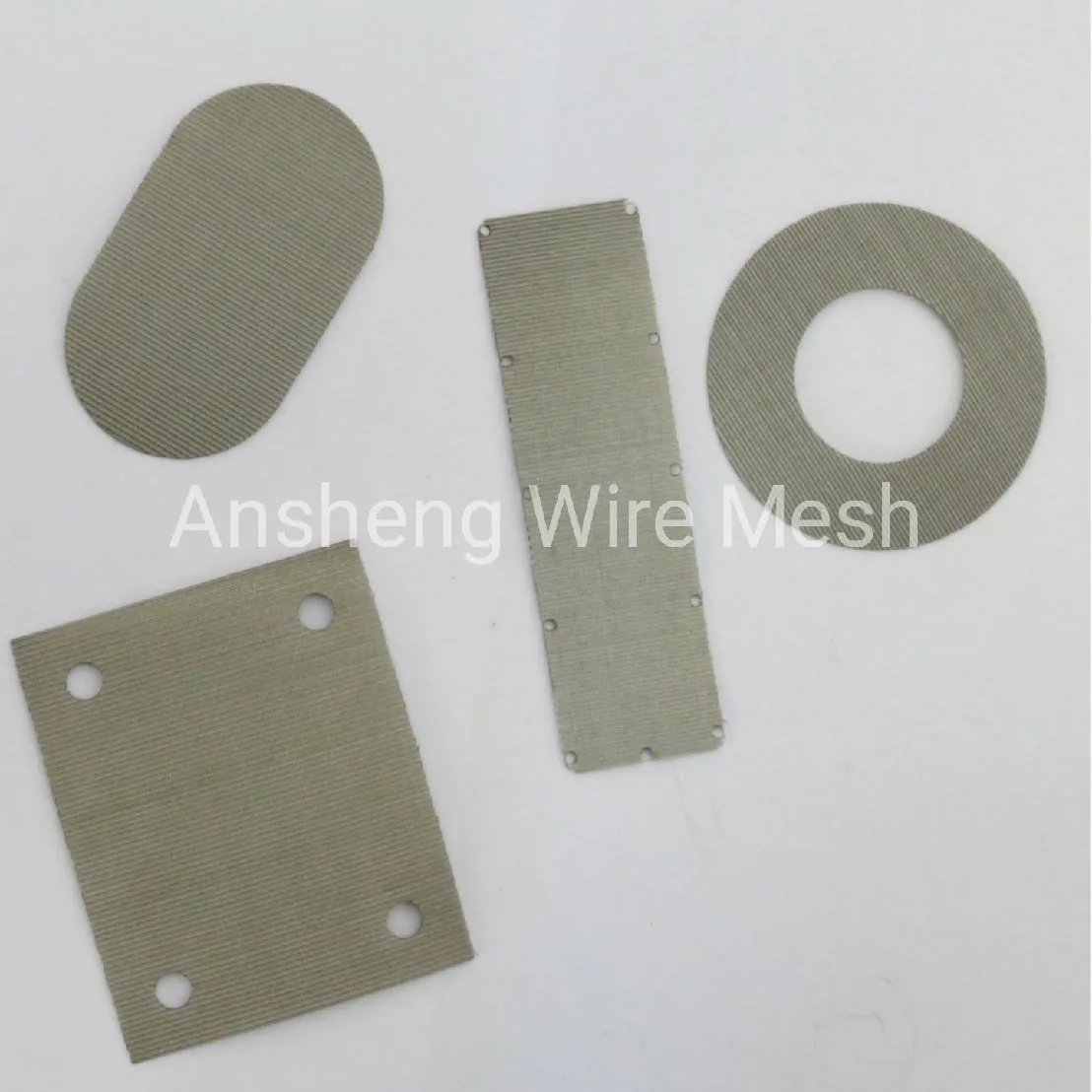

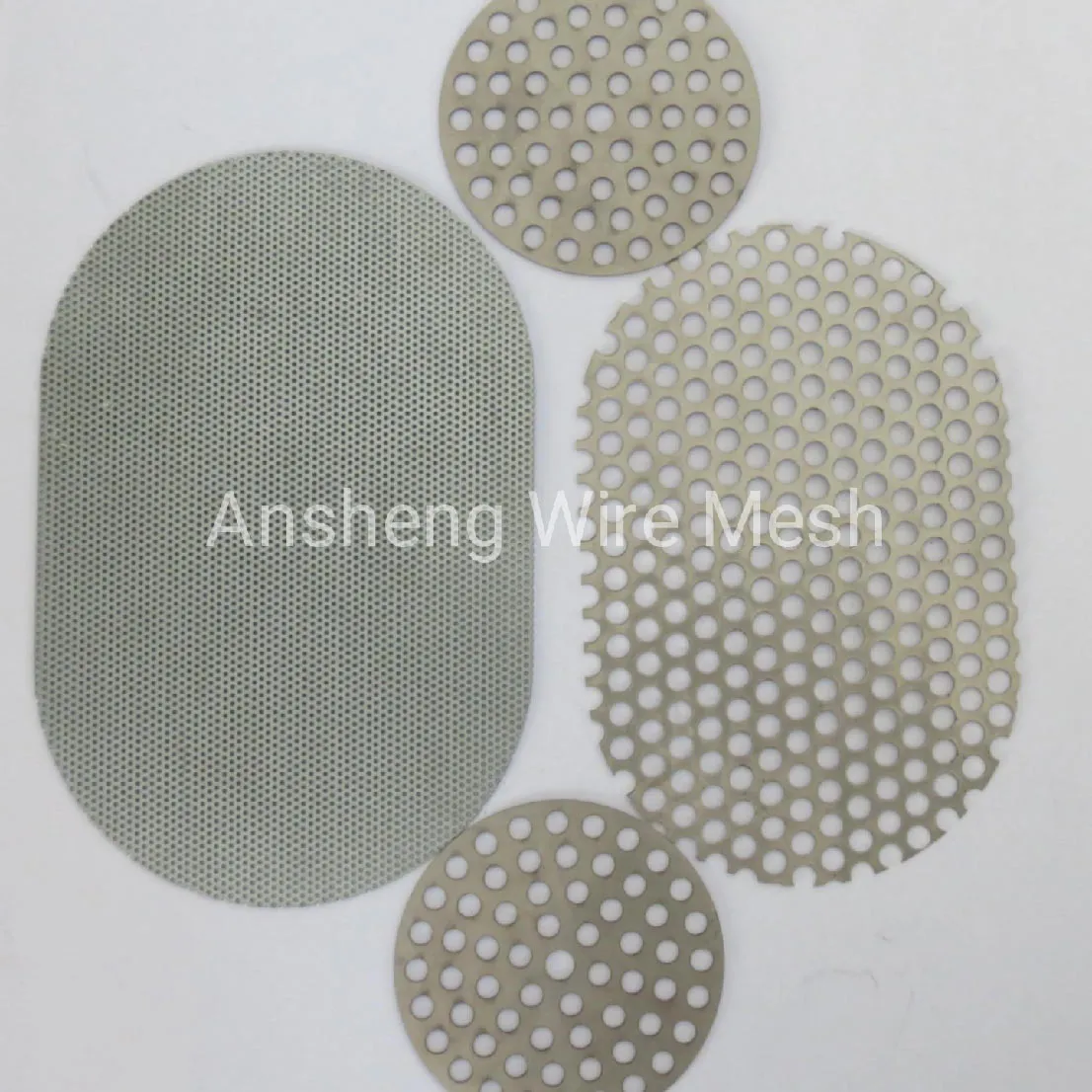

The Single Layer Wire Mesh Discs are engineered to provide precise filtration and screening solutions for a wide range of industries. These discs are characterized by their high-quality materials, fine weaving techniques, and accurate specifications, ensuring optimal performance in demanding environments. Whether you require a custom-cut disc for a specific application or a standard size for general use, our products are designed to meet your needs with minimal waste and maximum efficiency.

Key Features and Advantages

Our Single Layer Wire Mesh Discs are crafted with meticulous attention to detail, offering a range of features that set them apart from standard mesh products:

1. Shape Regularity

The edges of the mesh are neat and free from distortion or deformation, ensuring a regular shape that is easy to install and use. This precision guarantees stability during operation, reducing the risk of misalignment or failure in critical applications.

2. High-Quality Material Selection

We use high-purity and high-quality raw materials, including stainless steel 304, 316, 316L, nickel N6, nickel 200, and low-carbon steel, as well as galvanized options. These materials ensure excellent corrosion resistance, strength, and toughness, making the discs suitable for both harsh and sensitive environments.

3. Fine Weaving of Mesh

The mesh is tightly and evenly woven, with consistent mesh sizes and no defects such as skipping or leaking. This results in high filtration accuracy and superior aesthetics, ensuring that the product meets the highest industry standards.

4. Accurate Specifications

The dimensions of the mesh—length, width, and aperture—are precisely controlled to meet design requirements. Deviations are kept within allowable ranges, ensuring that the discs can be accurately installed and seamlessly integrated with other equipment or components.

5. Customization and Cost Efficiency

By working with advanced CNC machining equipment and an experienced technical team, we offer custom-cut mesh discs tailored to your specific needs. This approach eliminates waste from cutting errors, reduces material costs, and minimizes shipping expenses by delivering only the required quantity. Single Layer Wire Mesh Discs are not only worry-free but also cost-effective, surpassing the limitations of self-cutting.

Technical Specifications

Our Single Layer Wire Mesh Discs are available in a wide range of specifications to suit various applications:

| Parameter | Details |

|---|---|

| Materials | Stainless Steel 304, 201, 316, 316L; Nickel N6, Nickel 200, Nickel N4; Low-Carbon Steel; Galvanized |

| Mesh Size Range | 1–635 mesh |

| Dimension Range | 1 mm – 1 m |

| Shapes | Circle, Square, Oval, Kidney-Shaped, Rectangle, Irregular Shape |

| Types | Woven Wire Mesh, Perforated Mesh, Expanded Metal Mesh |

| Edge Finish | Smooth, Burr-Free, Neat Edges |

| Accuracy | Deviations Controlled Within Allowable Ranges |

Applications and Use Cases

The versatility of Single Layer Wire Mesh Discs makes them suitable for a wide array of industrial and commercial applications:

1. Filtration Systems

These discs are ideal for liquid and gas filtration in industries such as chemical processing, pharmaceuticals, and food and beverage. Their precise mesh sizes ensure effective particle separation while maintaining high flow rates.

2. Industrial Screening

The uniform mesh size and high strength of the discs make them suitable for screening and sorting operations in mining, agriculture, and construction. They can handle materials ranging from fine powders to coarse granules.

3. Automotive and Aerospace

Custom-cut Single Layer Wire Mesh Discs are used in air intake systems, fuel filters, and heat exchangers in the automotive and aerospace industries. Their corrosion resistance and durability ensure long-term performance in harsh environments.

4. Environmental and Water Treatment

The discs are employed in water purification systems and sewage treatment plants to remove contaminants and impurities. Their fine weaving and accurate specifications ensure high filtration efficiency and minimal maintenance.

5. Custom Manufacturing

With advanced CNC machining and experienced technical teams, we can produce custom-shaped and sized discs to meet unique project requirements. This flexibility is particularly valuable in prototyping, R&D, and specialized industrial applications.

Company Background and Commitment to Quality

Anping County Ansheng Wire Meshes Product Co., Ltd. is a leading manufacturer of wire mesh products, with a strong reputation for innovation, quality, and customer service. Located in Anping County, Hebei Province, China, the company has been in operation for over two decades, serving clients across the globe.

Our commitment to excellence is reflected in our strict production standards and comprehensive testing processes. We use state-of-the-art CNC machining equipment to ensure precision and consistency in every product. Additionally, our experienced technical team works closely with clients to understand their needs and deliver tailored solutions that meet or exceed expectations.

By focusing on customization, cost efficiency, and sustainability, we have become a trusted partner for industries that require high-performance wire mesh products. Our zero-waste cutting process and optimized logistics not only reduce costs but also minimize environmental impact, aligning with global trends toward sustainable manufacturing.

Why Choose Our Single Layer Wire Mesh Discs?

There are several compelling reasons to choose Single Layer Wire Mesh Discs from Anping County Ansheng Wire Meshes Product Co., Ltd.:

- Superior Quality: Our products are made from high-grade materials and undergo rigorous quality checks to ensure durability and reliability.

- Customization Options: We offer custom-cut and shaped discs to fit your specific requirements, reducing waste and saving costs.

- Cost-Effective Solutions: By eliminating the need for self-cutting and reducing shipping expenses, we provide competitive pricing without compromising on quality.

- Expertise and Experience: With over 20 years of experience in the industry, we have the knowledge and skills to deliver optimal solutions for any application.

- Global Reach: Our products are exported to numerous countries, and we provide professional support to ensure satisfaction for international clients.

Industry Standards and Certifications

As a reliable manufacturer, we adhere to international industry standards and certifications to ensure compliance and safety. Our Single Layer Wire Mesh Discs are designed to meet the requirements of ISO 9001 and ASTM standards, among others. These certifications guarantee that our products are safe, effective, and of the highest quality.

For further information on industry standards, you can refer to the National Institute of Standards and Technology (NIST), which provides comprehensive resources on material specifications and testing protocols [1].

Conclusion

Single Layer Wire Mesh Discs from Anping County Ansheng Wire Meshes Product Co., Ltd. are a premium solution for filtration, screening, and industrial applications. With their precise specifications, high-quality materials, and customization capabilities, these discs offer superior performance and cost efficiency. Whether you are in the chemical, automotive, or environmental industry, our products are designed to meet your needs and exceed your expectations.

For more details about our Single Layer Wire Mesh Discs and Anping County Ansheng Wire Meshes Product Co., Ltd., please visit our official website or contact us directly. We are committed to providing exceptional products and services to support your success.

References

[1] National Institute of Standards and Technology (NIST). Retrieved from https://www.nist.gov.

Post time: Jul . 30, 2025 13:20