When it comes to industrial filtration and material processing, the Single Layer Mesh Disc from Anping County Ansheng Wire Meshes Product Co., Ltd. stands out as a solution that combines advanced engineering with user-centric design. This product, available in a range of materials and specifications, is engineered to meet the rigorous demands of modern manufacturing, construction, and filtration systems. Whether you're looking for wire mesh discs or mesh sanding discs, this article provides a comprehensive overview of its features, advantages, and applications.

Product Overview

The Single Layer Mesh Disc is a specialized filtration component designed for precision and durability. Crafted with high-quality materials and advanced manufacturing techniques, it ensures optimal performance in a variety of industrial settings. The product's design emphasizes accurate specifications, uniform mesh size, and smooth edges, making it a reliable choice for applications that require consistent quality and efficiency.

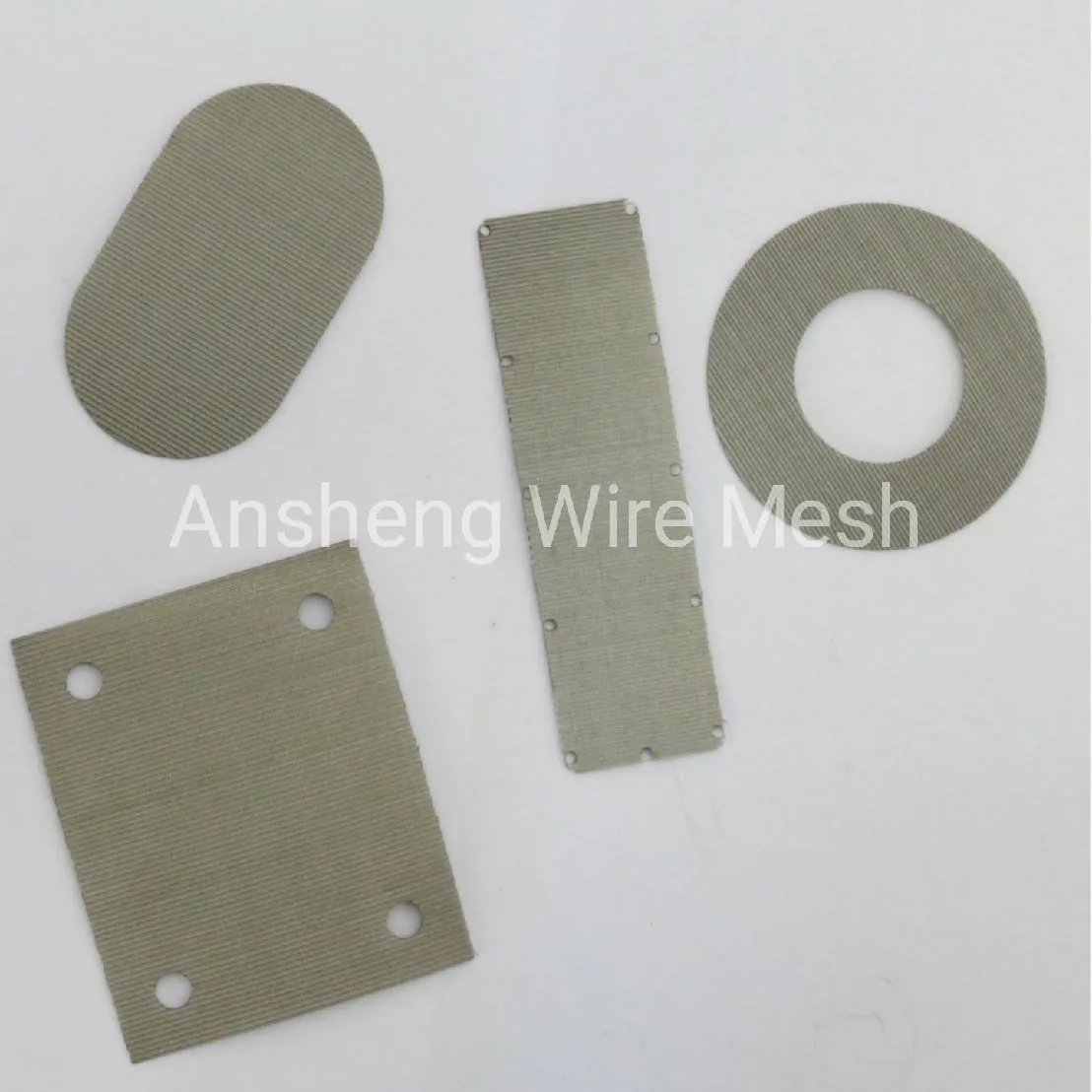

Image 1: Mesh sanding discs for industrial applications.

Key Features of the Single Layer Mesh Disc

The Single Layer Mesh Disc is distinguished by its exceptional design and construction. Below are the core features that set it apart:

1. Shape Regularity and Stability

The edges of the mesh are meticulously crafted to maintain a regular shape, ensuring no distortion or deformation. This precision allows for seamless installation and stable performance, even in high-stress environments. The uniformity of the design also enhances the product's longevity, reducing the risk of failure during operation.

2. High-Quality Materials

Manufactured using high-purity raw materials, such as stainless steel 304, 201, 316, and 316L, as well as nickel alloys and galvanized steel, the Single Layer Mesh Disc offers superior corrosion resistance, strength, and toughness. These materials are selected to withstand harsh conditions, ensuring the product remains functional and durable over time.

3. Fine Weaving and Filtration Accuracy

The mesh is tightly woven with consistent mesh sizes, eliminating defects like skipping or leakage. This meticulous weaving process guarantees high filtration accuracy, making it ideal for applications that require precise particle separation. The aesthetic quality of the mesh also contributes to its overall appeal in industrial and commercial settings.

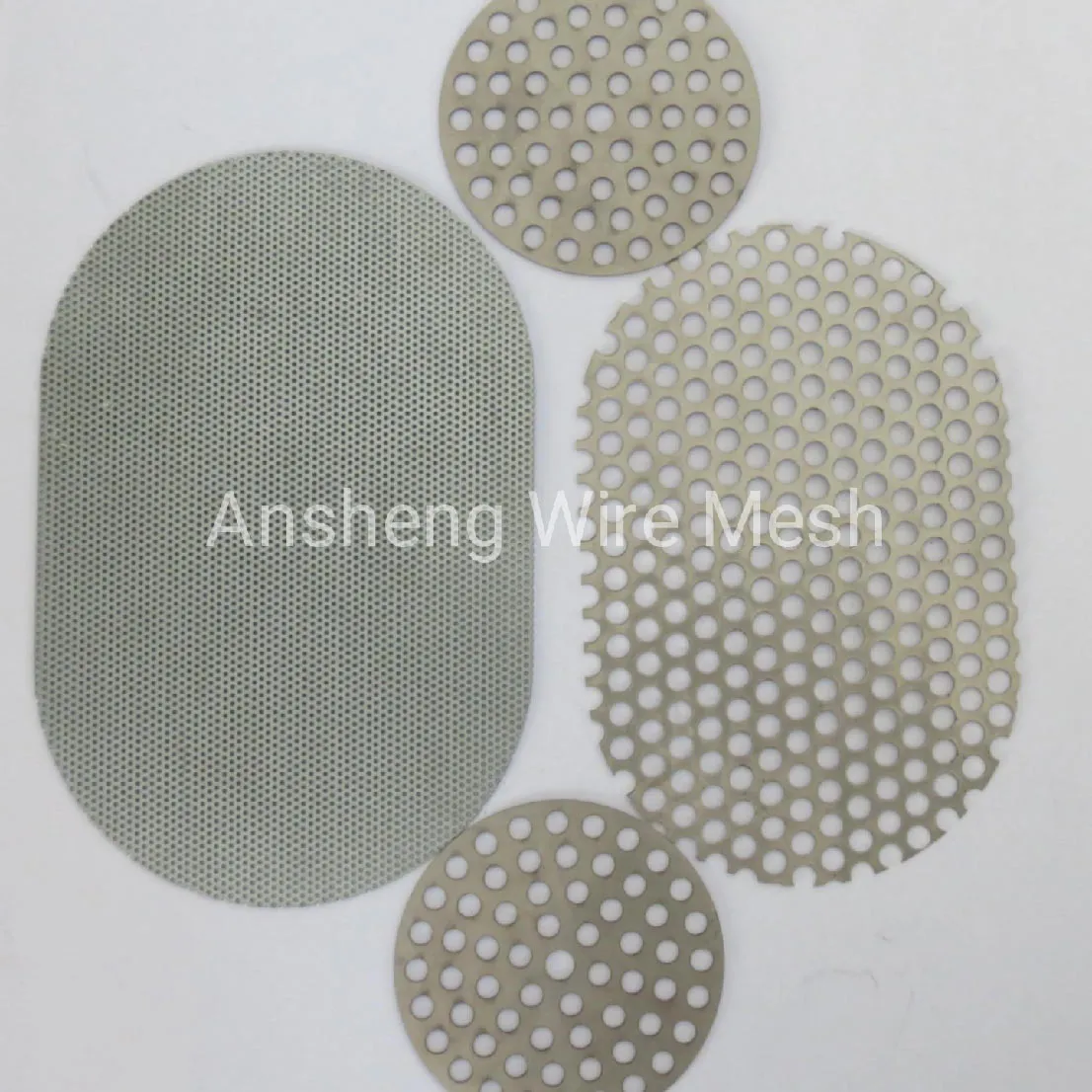

Image 2: Mesh disc with precise specifications.

4. Accurate Specifications

The Single Layer Mesh Disc is produced to meet strict dimensional requirements. Its length, width, and aperture are carefully controlled to ensure compatibility with existing equipment and systems. This level of accuracy minimizes installation challenges and ensures seamless integration into various applications.

Advantages of Customized Mesh Discs

One of the standout benefits of the Single Layer Mesh Disc is its customization options. By choosing a factory-direct wire mesh disc, customers can avoid the inefficiencies and costs associated with self-cutting. Here's how the product delivers value:

1. Precision Cutting and Waste Reduction

Traditional methods of purchasing full rolls of mesh and cutting them in-house often lead to significant waste due to cutting errors. The Single Layer Mesh Disc is manufactured with high-precision cutting techniques, ensuring no material is wasted. This not only reduces costs but also aligns with sustainable manufacturing practices.

2. Cost-Effective Logistics

By delivering only the required quantity of mesh, the Single Layer Mesh Disc minimizes transportation costs. This approach eliminates the need to ship large, uncut rolls, which can be expensive and logistically complex. The product's tailored delivery ensures customers pay only for what they need, enhancing cost efficiency.

3. Time and Labor Savings

The customization process eliminates the time and labor required for in-house cutting and preparation. This allows businesses to focus on core operations while ensuring their filtration systems are equipped with high-quality components. The Single Layer Mesh Disc is designed to be "plug-and-play," reducing installation time and minimizing the risk of errors.

Image 3: Mesh sanding discs for precision applications.

Technical Specifications

| Parameter | Details |

|---|---|

| Materials | Stainless steel 304, 201, 316, 316L, nickel N6, nickel 200, nickel N4, low-carbon steel, galvanized steel |

| Mesh Size Range | 1-635 mesh |

| Dimension Range | 1mm-1m |

| Shapes Available | Circle, square, oval, kidney-shaped, rectangle, irregular shapes |

| Types | Woven wire mesh, perforated mesh, expanded metal mesh |

| Surface Finish | Smooth, burr-free edges |

Applications of the Single Layer Mesh Disc

The versatility of the Single Layer Mesh Disc makes it suitable for a wide range of industries. Some of its primary applications include:

1. Filtration Systems

Used in filter discs for water treatment, chemical processing, and industrial air filtration, the product ensures efficient separation of particles and contaminants. Its accurate specifications and uniform mesh size make it ideal for applications requiring high precision.

2. Construction and Manufacturing

The Single Layer Mesh Disc is utilized in construction for reinforcing materials and in manufacturing for quality control processes. Its durability and resistance to corrosion make it a preferred choice for structural and functional components.

3. Automotive and Aerospace

Industries such as automotive and aerospace rely on the product for filtration and component manufacturing. The high-quality materials and fine weaving ensure compliance with stringent industry standards.

Company Background: Anping County Ansheng Wire Meshes Product Co., Ltd.

Founded in Anping County Ansheng Wire Meshes Product Co., Ltd., the company has established itself as a leader in the production of wire mesh discs and related products. With a focus on innovation and quality, the company leverages advanced CNC machining equipment and a team of experienced engineers to deliver precision-crafted solutions. Their commitment to accurate specifications and uniform mesh size has earned them a reputation for reliability and excellence in the industry.

Conclusion

The Single Layer Mesh Disc from Anping County Ansheng Wire Meshes Product Co., Ltd. is a testament to the power of precision engineering and customer-centric design. With its high-quality materials, customizable options, and wide range of applications, it addresses the needs of modern industries seeking efficient and durable solutions. Whether you're in the filtration, construction, or manufacturing sector, this product offers the performance and reliability required to meet today's challenges.

References

For further information on materials science and industrial standards, refer to the National Institute of Standards and Technology (NIST). NIST provides authoritative resources on measurement science, materials testing, and manufacturing standards. Visit https://www.nist.gov for detailed research and guidelines.

Source: National Institute of Standards and Technology (NIST). (n.d.). Retrieved from https://www.nist.gov.

Post time: Oct . 06, 2025 02:25