Epoxy Coated Wire Mesh for Concrete: field notes, specs and real-world buying tips

If you’re weighing reinforcement options for slabs, precast, or shotcrete, you’ll run into epoxy coated wire mesh for concrete sooner than later. I’ve toured a few plants this year, and—surprisingly—the conversation has shifted from “is epoxy worth it?” to “how do we verify coating quality and bond?” That’s progress.

Where the market is heading

Infrastructure owners want longer service life, fewer shutdowns. So engineers specify epoxy coated wire mesh for concrete in coastal decks, parking structures, wastewater plants—anywhere chloride attack is a headache. In parallel, precasters are asking for tighter tolerances and clean welds. On the civil side, I keep seeing it as safety protection mesh in high-end apartments and offices. Two very different jobs, same DNA.

Quick specifications (typical)

| Base material | Low-carbon steel wire (≈ SAE 1008/1010), welded wire reinforcement |

| Wire diameter | 0.5–2.5 mm (custom up to 4.0 mm) |

| Opening/Mesh count | 1×1 mm to 20×20 mm; common: 2×2, 4×4, 6×6 mm |

| Epoxy coating thickness | 60–120 μm (ASTM D1186 measurement; project needs vary) |

| Salt spray resistance | ≥ 720–1000 h (ASTM B117 / ISO 9227) |

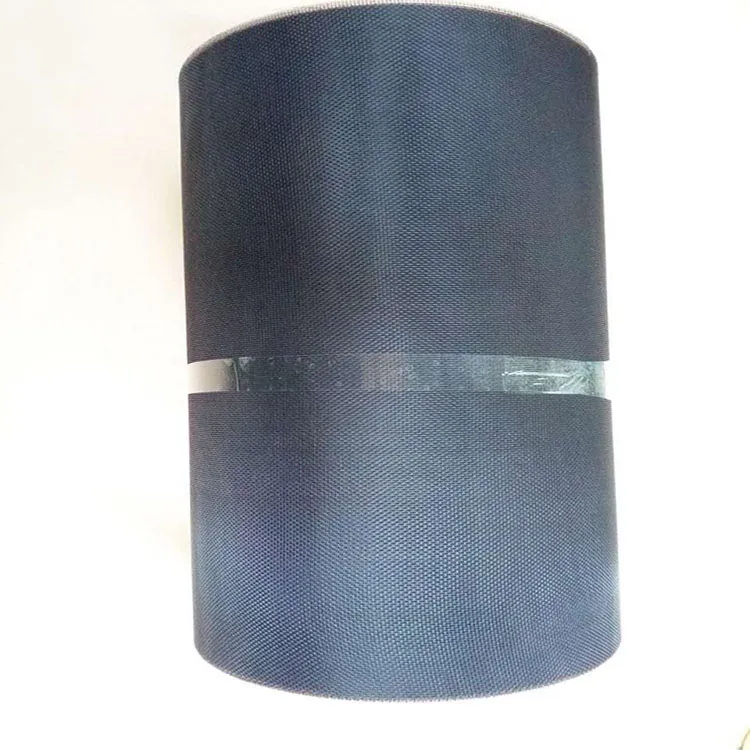

| Panel/Roll sizes | Panels up to 2.4×6 m; rolls up to 2 m width |

| Expected service life | 15–30+ years depending on exposure and cover (real-world use may vary) |

How it’s made and tested (the short version)

Process flow I’ve seen at Ansheng: wire drawing → straightening → resistance welding → alkaline degrease → shot cleaning → phosphate or silane treatment → electrostatic epoxy powder spray → curing → 100% inspection.

- Standards: ASTM A1064/A1064M (WWR), ASTM A884/A884M (epoxy-coated wire), ACI 318 guidance, ISO 9001 QMS.

- Tests: coating thickness (ASTM D1186), adhesion (ASTM D3359), salt spray (ASTM B117/ISO 9227), bend test (per A884), holiday/pinhole ≤ 3 defects/m² typical.

- Traceability: heat/lot marks and cure charts—ask for them; it matters.

Applications and advantages

- Bridge and parking decks, marine piers, wastewater tanks, tunnel liners, precast façades, slabs-on-grade with de-icing salts. Also: safety protection mesh for upscale apartments and offices (nice crossover use).

- Why choose epoxy coated wire mesh for concrete? Corrosion resistance in chloride-rich environments, clean handling, and consistent weld shear. It maintains dependable bond performance when specified correctly and installed with proper cover.

Vendor snapshot (what buyers compare)

| Vendor | Coating quality | Lead time/MOQ | Customization | Certs |

|---|---|---|---|---|

| Ansheng Wire Mesh (Anping, Hebei; No.346 Xinying East St.) | Uniform 60–120 μm; low pinholes | ≈ 2–4 weeks; MOQ flexible | Openings, wire dia, panel/roll, RAL colors | ISO 9001; test reports per lot |

| Generic Importer | Variable; spotty documents | 4–8 weeks; higher MOQ | Limited SKUs | Basic COA; incomplete data |

| Local Fabricator | Good welds; outsourced coating | Short runs; quick for stock sizes | Custom cuts; fewer color options | Project-based reports |

Customization, colors, logistics

Colors: classic green (RAL 6005), black, gray—others on request. Packaging: flat panels with corner guards or rolls with cores; export pallets. To be honest, many customers say custom panel sizes reduce waste noticeably on site. Ansheng’s team also builds the same mesh as a filter support layer for hydraulic/air filters—another hat the epoxy coated wire mesh for concrete wears well.

Case snapshots (condensed)

- Coastal parking deck overlay: 4×4 mm opening, 1.8 mm wire, 100 μm epoxy; >1000 h salt spray; owner chose epoxy to extend maintenance intervals.

- Wastewater tank baffle panels: tight mesh, black epoxy to reduce glare; holiday testing on-site caught two pinholes—quickly repaired.

- High-rise safety mesh: green finish, clean edges—architect liked the discreet look; residents noted “no rust streaking,” which is nice.

Final note: documentation matters. Ask for A884 bend/adhesion results, D1186 thickness logs, and B117/ISO 9227 hours. It seems basic, but it’s the difference between “should last” and “will last.”

References

- ASTM A884/A884M – Epoxy-Coated Steel Wire and Welded Wire Reinforcement.

- ASTM A1064/A1064M – Carbon-Steel Wire and Welded Wire Reinforcement for Concrete.

- ASTM B117 / ISO 9227 – Salt Spray (Fog) Testing; ASTM D1186 – Coating Thickness; ASTM D3359 – Adhesion; ACI 318 Durability Provisions.

Post time: Oct . 06, 2025 00:45