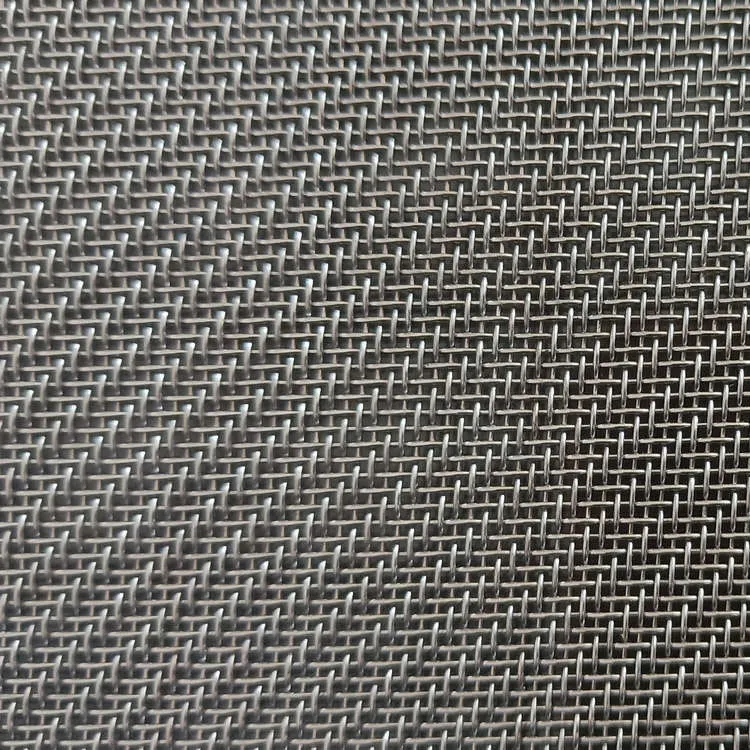

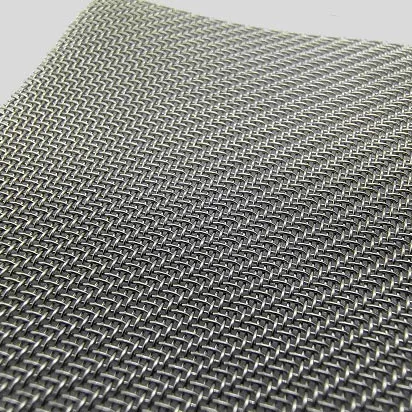

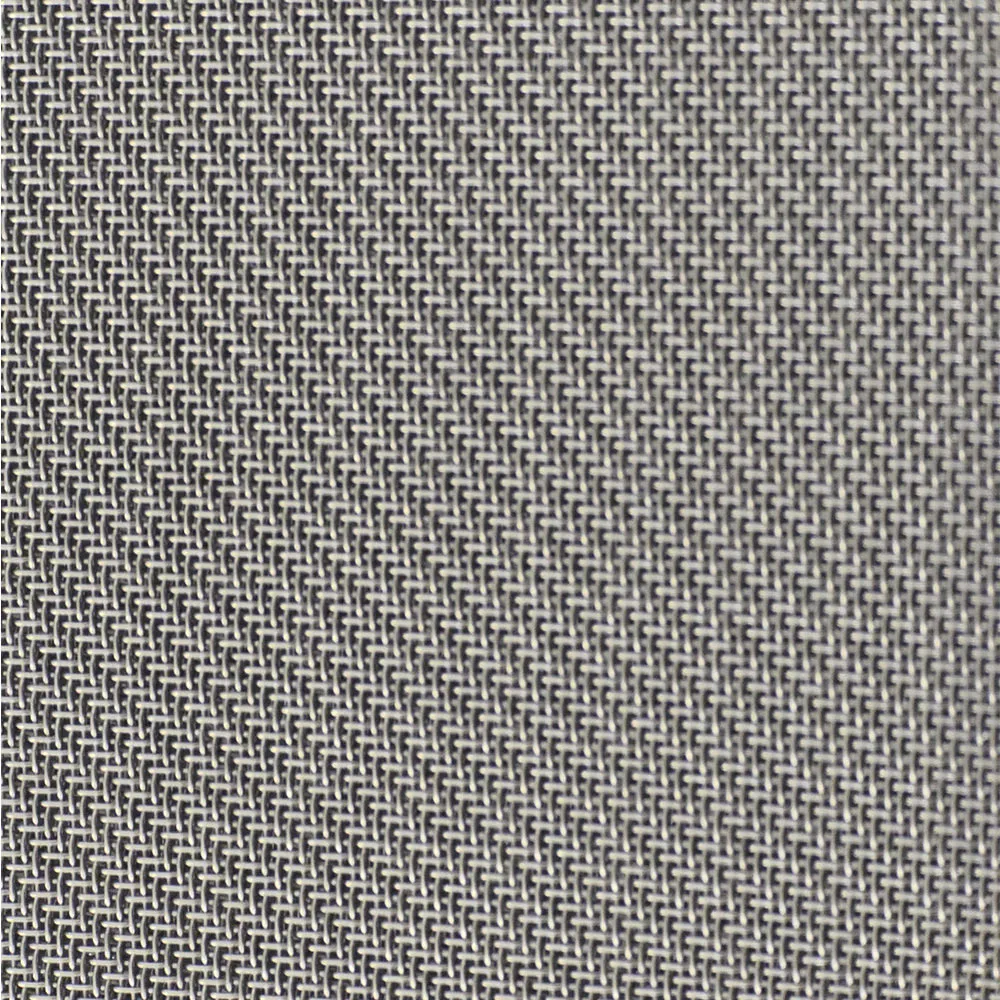

As industrial filtration and precision engineering progress, the twill weave mesh family—incorporating twill weave wire mesh and twill mesh—stands at the forefront of advanced material science and process technology. This article presents a data-driven, expert perspective on technological parameters, process control, application scenarios, and market landscape, focusing on the performance and customization of Stainless Steel Twill Weave Wire Mesh for critical industries.

According to the Markets & Markets 2023 report, the global wire mesh market is expected to surpass USD 11.3 billion by 2027, with twill weave mesh segments showing CAGR above 6.2% due to their superior filtration precision and mechanical strength advantages in petroleum, petrochemical, aerospace, pharmaceutical, and environmental engineering.

① Raw Material Inspection (SUS 304/316L certified wire rod)→ ② Pre-Processing (Pickling, Annealing)→ ③ CNC Drawing & Wire Sizing (±0.001 mm tolerance)→ ④ Twill Weaving (Auto shuttle looms, tension monitoring)→ ⑤ Surface Cleaning (Ultrasonic/Fine Washing)→ ⑥ Quality Inspection (ISO/ASTM mesh count; micro-CT analysis)→ ⑦ Finished Packing (Vacuum/anti-rust packaging)

- Materials: 316L stainless steel is most widely chosen for pharmaceutical and high-corrosion settings; meets ASTM A580, EN10204, FDA requirements.

- Processing: CNC-controlled weaving achieves mesh uniformity ≤2%. Twin wire path ensures consistent twill pattern and edge flatness.

- Inspection: Each batch is tested per ISO 9044 & ASTM E2016-20.

- Service Life: >10 years for standard chemical, water, or petrochemical uses, proven by industrial benchmarks.

| Mesh Count | Wire Diameter (mm) | Aperture (μm) | Open Area (%) | Standard Grade | Roll Width (m) |

|---|---|---|---|---|---|

| 80 | 0.12 | 202 | 33 | 316L/304 | 1.0/1.2/1.5 |

| 165 | 0.071 | 83 | 28 | 316L/304 | 1.0/1.2 |

| 200 | 0.053 | 63 | 26 | 316L | 1.0 |

| 325 | 0.035 | 38 | 22 | 316L | 1.0 |

| 400 | 0.027 | 32 | 21 | 316L | 1.0 |

| 500 | 0.025 | 25 | 19 | 316L | 1.0 |

| 635 | 0.020 | 20 | 18 | 316L | 1.0 |

2. Metallurgy: Used as sintering mesh, sieve plates and hot gas filtration; superior strength-to-aperture ratio ensures stability under thermal cycling.

3. Water Treatment: Employed in membrane pre-filtration, desalination plants, sand removal—regardless of flow velocity.

4. Pharmaceutical & Food: Certified for FDA, ISO 9001:2015, EN10204 compliant production, hygienic design for CIP/SIP processes.

| Company | Strengths | Certifications | Custom Options | Key Markets |

|---|---|---|---|---|

| Boegger Industrial | High mesh count, quick shipping | ISO 9001, SGS | Yes (OEM) | Chemical, Minery, Gas |

| Ansheng Filter Screen | Ultra-fine mesh, medical grade, integrated QC | ISO 9001:2015, FDA, EN10204 | Yes, full process | Pharma, Water, Food |

| BZ Wire Mesh | Advanced weaving, price competitive | CE, ISO | Custom mesh | Industrial, Machinery |

| Edward J. Darby & Son | 150+ years, extensive alloys | ASTM, RoHS | OEM+ | Aerospace, Filtration |

- Custom Mesh Design: Aperture, thickness, surface treatment (electropolish, passivation), or alloy (Nickel, Monel, 316Ti) per project requirement.

- Precision Slitting & CNC Shaping: Mesh can be slit to 4mm widths with edge welding, or formed into discs, filter elements, tubes.

- Delivery Cycle: Standard mesh: 3–7 working days; custom structures: 10–20 days (ISO 9001:2015 traceability on process/control records). Worldwide express & ocean shipment available.

- Inspection & Traceability: Each order supplied with full test report — mesh count/CT scan, chemical analysis, mechanical property, visual QC.

- Warranty: 1-year replacement guarantee for industrial clients; food/pharma-grade: up to 18 months with certification.

Professional FAQ: Twill Weave Mesh Technical Terms

- 1. What is “Mesh Count” and why does it matter?

- Mesh count refers to the number of apertures per linear inch. Higher mesh counts enable finer filtration, but require finer wire and tighter tolerances. In twill weave mesh, mesh count influences both flow rate and filtration precision.

- 2. Which stainless steel grades are commonly used?

- Primary grades include SUS304 (general corrosion resistance), 316 & 316L (superior resistance to acids/chlorides), and specialty alloys (321, Monel, Hastelloy) for demanding environments.

- 3. What are the main installation standards for industrial facilities?

- Referenced standards include ISO 14644 (for cleanrooms), ASTM E2016-20 (for wire cloth), and user-specific requirements (e.g., FDA 21CFR211 for pharma).

- 4. How does twill weave’s structure benefit filtration?

- Twill weave (“two over two under”) allows the use of thicker wires at the same mesh count, improving mechanical strength and service life versus plain weave. This structure supports higher pressure drops and resists wire deformation.

- 5. What is “Electropolishing” and when is it necessary?

- Electropolishing smooths and passivates the wire mesh surface at a micro level, removing embedded contaminants and reducing bacterial retention. It's essential for food, pharma, and semicon applications.

- 6. How is mesh quality assured?

- Mesh is inspected per ISO 9044 for mesh count, wire integrity, burr presence, and evenness. Micro-CT scanning and optical 3D measurement validate internal structure and aperture size.

- 7. What is the typical service temperature range?

- Stainless Steel Twill Mesh generally operates from -196°C (cryogenic) up to 650°C, limited by the steel grade and atmosphere. For higher temperatures, Inconel or FeCrAl alloy is advised.

- Bulk Order Handling: Professional support for LCL/FCL, with detailed packing lists and batch traceability, signed-off by ISO-certified staff.

- Dedicated Pre-sales Consulting: Engineers provide aperture/wire selection, process-fit, project drawings in CAD/3D per client process.

- After-sales Warranty: Free replacement within 1 year for non-manmade faults; food/pharma applications up to 18 months.

- Technical Support: 24/7 expert response via email, phone, and on-site visit (EMEA/Asia).

- Case Documentation: Each project has a full material/test/usage record for compliance audit.

- ISO 9044: Specifications for industrial wire cloth

- Industrial Filtration Forum: Wire Mesh in Filtration Best Practices

- Materials Performance Journal: Case Studies on Stainless Steel Filter Mesh

- FDA CFR 21, Part 211: Good Manufacturing Practice for Pharma

Post time: Aug . 04, 2025 12:20