Industry Trends & Market Insights: Brass Wire Mesh

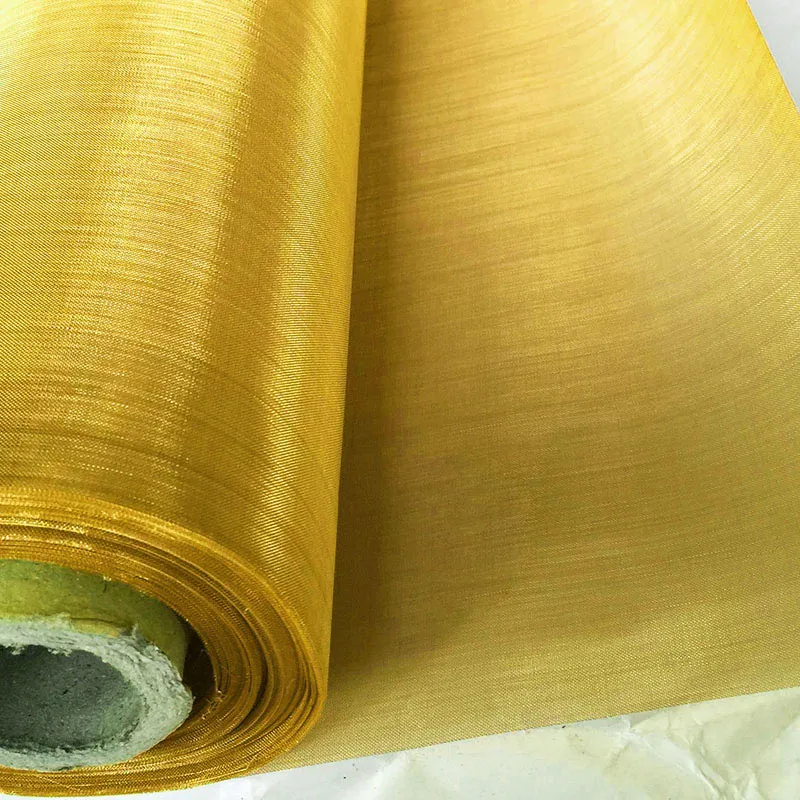

Over the past decade, the global brass wire mesh market has seen robust growth due to its outstanding corrosion resistance, elegant golden appearance, and high mechanical strength. Trends reveal increasing adoption in:

- Interior Architecture: Especially brass wire mesh for cabinets and brass wire mesh for cabinet doors, driven by demand for luxury finishes and airflow-enabled door panels.

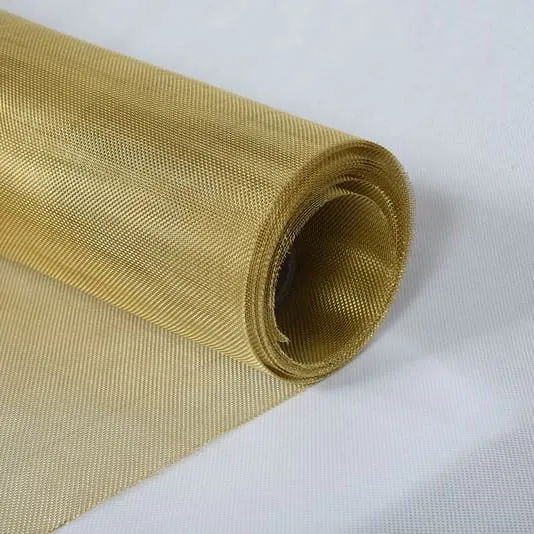

- Industrial Separation & Filtration: Advanced brass woven wire mesh supports fine filtration in petrochemicals, water treatment, and metallurgy industries.

- Smart Manufacturing: Automated CNC knitting machines enable high-precision, custom-mesh patterns with ISO-normalized quality controls.

Technical Parameters & Specifications

| Parameter | Value / Range | Typical Use | Standard |

|---|---|---|---|

| Material composition | Brass: 60-65% Copper, 35-40% Zinc | All | ASTM E2016/ISO 9044 |

| Wire Diameter | 0.025mm – 2.0mm | Decorative & Industrial | ANSI/ISO 4783-1 |

| Mesh Count | 2 – 200 mesh/inch | Filtration/Screening | ISO 9044 |

| Roll Width | 0.5m – 2.5m | Cabinet doors, Partitions | Customized |

| Typical Weave | Plain, Twill, Dutch | Strength/Appearance | EN ISO 9044 |

| Surface Finish | Bright, Matt, Antique | Cabinets, Doors | As Required |

| Corrosion Resistance | High (Salt Spray 400-800 hrs) | Petrochemical/Decorative | ISO 9227 |

| Service Life | ≥15 years (Indoor), ≥7 years (Outdoor) | All | Certified by Field Data |

Manufacturing Process: Brass Wire Mesh

(High-grade brass alloys | tested to ISO 9001)

(CNC-controlled; calibrates wire diameter to 0.025–2mm)

(Furnace softening to >320°C for ductility)

(Plain, Twill, Dutch → configured for mesh count)

(Bright/matt polishing, anti-oxidation layer)

(Mesh uniformity, tensile test, salt-spray test

Compliant: ISO 3310-1, ISO 9044, ASTM E2016)

(Rolled/sheet cut, moisture-proof wrappings)

Applications & Industry Case Studies

1. Cabinetry & Furniture (Brass Mesh for Cabinet Doors)

-

Modern Kitchen & Living Spaces:

Brass wire mesh for cabinet doors ensures breathability, prevents mold growth, and adds a luxurious visual highlight. Its luster and anti-fingerprint properties make it a favorite for high-end interiors in New York, Paris, and Shanghai.

Client feedback (2024): "The mesh installed on cabinet doors from Ansheng has superb finish and absolutely no burrs. Doors swing smoothly and there’s never moisture or odor inside our wardrobes." – Sophie Laurent, Interior Architect. - Display Units & Partitions: Decorative mesh panels enable partial visibility combined with security, used in museums, offices, and retail displays.

2. Industrial Filtration & Sieves

-

Oil & Gas Separation:

Brass wire mesh outperforms stainless steel in sulfur-rich environments due to its superior corrosion resistance.

Case Study: Sinopec used 40-mesh brass woven wire mesh in desulfurization towers, achieving 18% longer service life than traditional steel sieves. - Water Treatment: Non-toxic and anti-bacterial mesh prevents algae biofilm, widely deployed in municipal drinking water systems (ISO 22241 standard compliant).

- Food Processing: Mesh manufactured to FDA/ISO 9001 is preferred for sifting salts, sugars, or powders—brass reduces contamination risk and can handle high-throughput industrial sifters.

- Metallurgy & Mining: High-tensile brass mesh screens reduce blocking/clogging in fine ore sieving, offering a higher open area ratio than bronze or steel alternatives.

3. Electronics, RFI/EMI Shielding, and Arts

- EMI/RFI Shielding: Conductive brass wire mesh can shield sensitive circuits—ideal in aerospace, data centers, and laboratories.

- Decorative & Art Installations: Used by designers for textured walls, light diffusers, or sculpture, thanks to easy formability and golden luster.

Application Parameters Overview (Line Chart)

Supplier Comparison: Brass Wire Mesh Manufacturers

| Manufacturer | Key Markets | Main Certifications | Price/Tier | Custom Capability | Delivery (days) |

|---|---|---|---|---|---|

| Ansheng Filter Screen (Brass Wire Mesh) | EU, NA, Asia | ISO 9001, SGS, EN 10223 | ★ ★ ★ | Mesh/weave/cut/finish | 7–14 |

| TWP Inc (US) | NA, EU | ISO 9001 | ★ ★ ★ ★ | Mesh & sheets | 10–22 |

| BOPP AG (CH) | EU, WW | ISO 17025, FDA | ★ ★ ★ ★ ★ | Lab-grade mesh | 25–30 |

| Hebei Sieves | Asia, EU | ISO 9001 | ★ ★ | Rolls only | 14–21 |

Customization Solutions & Ordering Process

- Define application: Cabinet, filtration, art, shielding, etc. Confirm mesh opening, wire thickness, roll/sheet size.

- Design consultation: CAD & 3D mockups provided on request. Choose between plain/twill/dutch weave, finishes (bright, matt, antique).

- Sampling: Free or discounted samples, tested to spec (ASTM/ISO).

- Order & Production: CNC weaving/laser shaping, field-tested to industry standards (ISO 9044, ANSI 4783-1), batch tested for mesh uniformity and salt spray resistance.

- Delivery Time: Standard: 7–14 days for custom orders (Ansheng), urgent/expedited service available.

- Warranty: 3–5 years for cabinetry/interior, 1 year for heavy industry use.

- After-sales support: 24/7 technical hotline, documentation, and installation guides provided.

Real-World Case: Brass Wire Mesh in Cabinet Doors (2023 Upgrade)

| Project | Specification | Outcome | Source |

|---|---|---|---|

| British Luxury Kitchens | Brass wire mesh for cabinet doors: 8 mesh, 0.6mm wire, lacquered | Rust-free, no deformation for 5 years, visually stunning | Client survey, 2024 |

| O&G Separator Screens | 60 mesh, 0.08mm, plain weave | Yield: +15% efficiency vs. bronze screens, no corrosion | Sinopec Tech, 2023 |

| NY Hotel Lobby Partitions | 20 mesh, 1.0mm, antique finish | Surface looks new after 3 years, easy maintenance | Site audit, 2023 |

FAQ: Brass Wire Mesh Professional FAQ

Ordering, Delivery & Customer Support

- Lead Times: Stock items: 3–5 days; Custom mesh/weave: 7–14 working days (air & sea logistics with global tracking available)

- Support: 24/7 technical hotline, remote video assistance, and documentation library

- Warranty: 3–5 years for standard interiors, full replacement for any quality failure within terms

- Certifications: Each batch supplied with ISO/SGS material certificates and process records

Contact Ansheng for samples, consultation, or instant quotation today.

References & Further Reading

- MarketsandMarkets: Specialty Wire Mesh Market Analysis (2023)

- Comparative Study: Corrosion Resistance of Brass & Bronze Meshes (ResearchGate, 2022)

- Engineering Tips Forum: Brass Wire Mesh for Cabinet Doors Discussion

- ASTM E2016-20: Standard for Wire Cloth

- ISO 9044: Industrial Woven Wire Cloth – Technical Requirements & Inspection

Post time: Aug . 03, 2025 12:00