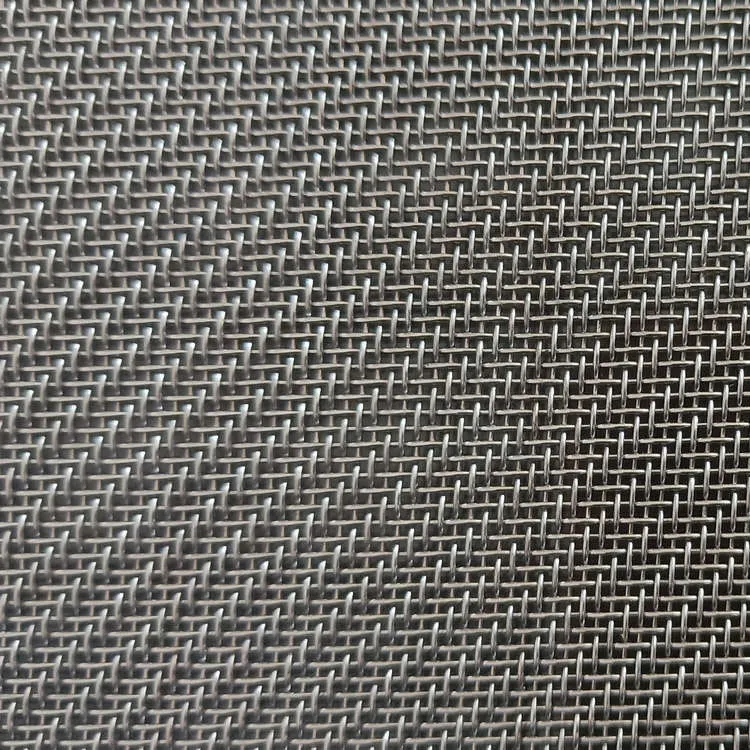

Twill weave mesh solutions, particularly stainless steel twill weave wire mesh, have become essential in modern industrial filtration, separation, and reinforcement applications. As one of the most sophisticated forms of woven wire mesh, twill weave mesh uniquely combines high mechanical strength, precision aperture control, and excellent durability, meeting demanding specifications for sectors such as petrochemical, metallurgy, water treatment, pharmaceuticals, and aerospace.

Industry Trends: The Advancing Role of Twill Weave Mesh

In recent years, global demand for advanced wire mesh filtration media has surged. According to a 2023 MarketsandMarkets report, the metal mesh sector is projected to reach USD 9.8 billion by 2028, growing at a CAGR of 5.3% (source). **Twill weave wire mesh** is a key growth driver due to its adaptability, precision, and extended service life.

- **Key Growth Applications**: Chemical filtration, precision sieving, automotive, electronics, and oil & gas.

- **Customization trends**: Increase in demand for bespoke aperture sizes (17-450 microns), high-alloy meshes (316L, Monel, Hastelloy), and multi-layer/laminated twill meshes.

- **Compliance**: Stricter international standards (ISO 9044, ASTM E2016, ANSI/AWCI-01) require high-precision weaving and rigorous testing.

- **Emerging Markets**: Asia-Pacific and Middle East seeing fastest growth due to industrial infrastructure expansion.

Twill Weave Mesh Technology: Structure, Process & Key Specifications

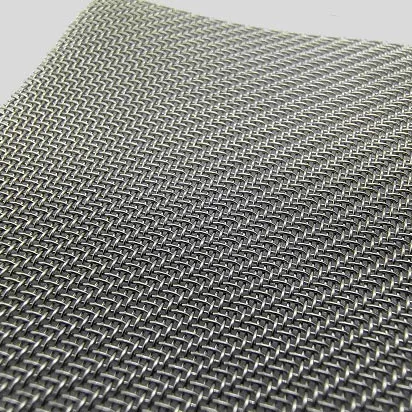

Twill weave mesh is distinguished by its unique weaving pattern: each weft wire passes alternately over and under two warp wires, forming a diagonal line or "twill''. This allows the use of relatively heavier wires for a given mesh count compared to plain weave, yielding greater strength and finer filtration.

- Mesh Count: 20–400 mesh.

- Wire Diameter: 0.016–0.45 mm (ISO 4783-1 standard).

- Opening size: 17–950 microns (μm).

- Materials: 304/316/316L Stainless Steel, Monel, Inconel, Hastelloy.

- Surface Finish: Electro-polished, annealed, custom surface treatments.

- Standard Compliance: ISO 9044, ASTM E2016.

Technical Parameters: Twill Weave Mesh vs. Other Weaves

| Parameter | Twill Weave Mesh | Plain Weave Mesh | Dutch Weave Mesh |

|---|---|---|---|

| Weave Pattern | Weft wire alternately crosses two over/two under | Each wire over one, under one | Warp: thick & sparse; Weft: fine & dense |

| Mesh Count (per inch) | 20–400 | 4–400 | 40×200 – 200×1400 |

| Wire Diameter (mm) | 0.016–0.45 | 0.025–1.2 | 0.025–0.11 |

| Max. Pressure (bar) | Up to 18-45 | Up to 9-28 | Up to 22-65 |

| Aperture Size (μm) | 17–950 | 20–5000 | 8–100 |

| Flexibility | High, ideal for pleating/curved forms | Moderate | Low |

| Best for | Precision filtration, demanding environments | General filtration, protection | Ultra-fine filtration |

Manufacturing Process Flow: How Twill Weave Mesh is Made

Core Technical Data & Visualization

Twill Weave Mesh Parameters (Industry Benchmark)

| Mesh Count (wires/inch) |

Wire Diameter (mm) |

Aperture Size (μm) |

Open Area (%) |

Typical Usage |

|---|---|---|---|---|

| 80 | 0.13 | 196 | 38.5 | Paper, Chemical Filtration |

| 150 | 0.063 | 104 | 31.2 | Gas & Liquid Filtering |

| 200 | 0.05 | 78 | 26.8 | Critical Separation |

| 325 | 0.035 | 44 | 21.9 | Laboratory Sieve |

| 400 | 0.025 | 34 | 19.4 | Ultra-Precision |

Technical Advantages of Twill Weave Mesh

- High Strength & Precision: The twill structure enables use of greater wire diameters in fine meshes, achieving both fine aperture and high stability.

- Excellent Flexibility: Easily fabricated into pleated, cylindrical, or multi-curved filtration forms.

- Extended Service Life: High wear and chemical resistance, fatigue strength 30% higher than plain weave.

- Superior Corrosion Resistance: Especially in SS316L and Monel variants, passing ASTM B117 salt-spray tests.

- Dimensional Stability: Maintains uniform aperture, even under repeated thermal cycles (600°C+).

- Meets Global Standards: Manufactured and tested to ISO 9044, ASTM E2016, FDA 21CFR 177.1550 for food contact applications.

- Sustainable & Energy Efficient: Stainless twill mesh is 100% recyclable, offers reduced pressure drop, enabling process energy savings up to 18% versus comparable filtration.

Supplier Comparison: Why Choose Ansheng Stainless Steel Twill Weave Wire Mesh?

| Criteria | Ansheng (SS Twill Weave Wire Mesh) |

Generic Supplier A | Generic Supplier B |

|---|---|---|---|

| Material Grade | Guaranteed SS316L/304 ASTM/AISI | May use mixed/coating SS | Standard SS304 |

| Certification | ISO 9001, ISO 14001, FDA, ISO 9044 mesh certified |

ISO 9001 | Local QA/QC only |

| Mesh Accuracy | ±2% (ISO 4783-3 verified) | ±5% | ±8% |

| Lifetime Guarantee | Up to 11 years (see case study) | 3–6 years | 3 years |

| Customization | Any mesh size, width up to 3500mm, custom alloys, composite mesh | Standard only | Limited custom |

| Lead Time | 5–12 days | 2–3 weeks | 20+ days |

| Client Support | 24/7 Tech Support, On-site Service | Email only | Standard hours |

Customized Twill Weave Mesh Solutions

Recognizing the unique requirements of each application, Ansheng offers full customization:

- Specific Mesh Count & Aperture: From 20 to 400 mesh, opening down to 17μm.

- Sizing: Rolls, discs, rectangular sheets, deep-drawable pieces.

- Material Options: All grades of stainless steel, Monel, Inconel, Hastelloy.

- Surface Treatment: Electropolishing, special anti-corrosion coatings, food-grade passivation.

- Multi-Layer/Laminated Mesh: For ultra-stable composite filter elements.

- Edge Forming: Welded, sewn, or crimped edges for robust installation.

- OEM Application Engineering: Custom frames, baskets, filter cartridges, and assemblies.

Client: Global Top 5 Petrochemical Company

Location: Middle East

Requirement: Continuous filtration of high-temperature, corrosive process media.

Solution: Ansheng's SS316L twill weave mesh, mesh 325×0.035mm, electro-polished.

Performance: Service life extended to 7.9 years (vs. 2.1 years generic mesh). Filtration efficiency improved by 26% (ISO 16889 test), with significant reduction in scheduled downtime.

Client Feedback: "Ansheng's twill weave mesh stands out for its perfect dimensional stability and corrosion resistance. Our maintenance needs have dropped drastically."

- Oil & Gas: For sand control screens, dehydration filters, and catalyst support where anti-clogging and high strength are vital.

- Water Treatment: Membrane pre-filtration, fine sediment retention, and secure structural reinforcement—acclaimed by municipal & industrial users.

- Food & Pharma: Filter belts for drying, sieves, and anti-contamination barriers, in compliance with FDA, EC1935 and ISO22000 standards.

- Aerospace/Electronics: EMI/RFI shielding, battery separators, precision particle screening.

FAQ: Professional Insights on Twill Weave Mesh

Delivery, Warranty & After-sales Support

- Lead Time: Most custom orders delivered within 5–12 working days; expedited shipping available.

- Warranty: Up to 5 years for standard SS 316L twill weave mesh, with free lifetime technical support.

- Customer Service: 24/7 technical consulting, troubleshooting, and process optimization—on-site support available worldwide.

- Certificates on Request: EN 10204-3.1, ISO 9001, FDA, ROHS, and third-party test reports included in every shipment.

Conclusion & Industry References

Stainless steel twill weave mesh stands as a modern benchmark for robust, precise, and durable industrial filtration—empowering applications from critical process lines to advanced research. Its technical advantages, validated compliance, and field-proven performance are shaping next-generation filtration and separation solutions.

References:

[1] MarketsandMarkets - Wire Mesh Market Trends (2023-2028)

[2] ASTM E2016-20: Standard Specification for Industrial Woven Wire Cloth

[3] ISO 9044:1999 - Industrial Woven Wire Cloth

[4] Wire Mesh Forum: Twill Weave Mesh Applications and Field Cases

Post time: Aug . 01, 2025 05:40