As the demand for advanced structural reinforcement and corrosion-resistant solutions rises in the concrete construction sector, epoxy coated wire mesh for concrete emerges as the industry gold standard. As a next-gen solution for high-performance infrastructures, it synergizes durability, precise engineering, and eco-efficiency. This comprehensive article explores market trends, technical parameters, meticulous manufacturing, use cases, and real-world data—ensuring industry decision-makers, engineers, and procurement professionals unlock its full value.

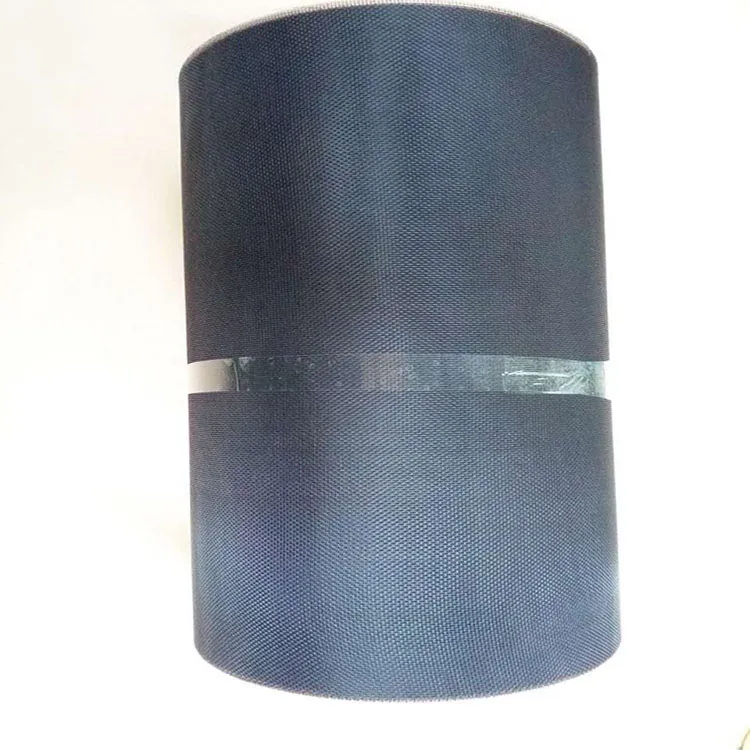

Epoxy Coated Wire Mesh Integrated in Major Concrete Infrastructure

Epoxy Coated Wire Mesh Integrated in Major Concrete Infrastructure (Image source: Ansheng Filter Screen Technologies)

1. Industry Overview & Market Trends

According to a 2023 MarketsandMarkets report, the global demand for epoxy coated wire mesh for concrete is projected to eclipse $800 million by 2027, with a sustained CAGR of 6.1%. This surge is fueled by rapid urbanization, infrastructure investment, and the rising need for maintenance-free, corrosion-resistant reinforcement.

- Resilience against aggressive environments—especially in marine, chemical, and metropolitan contexts

- Long lifecycle support for bridges, tunnels, parking structures, water facilities, and smart cities

- Eco-friendly manufacturing with minimized VOC emissions and extended recyclability of steel mesh substrates

Recent regulatory frameworks in North America and Europe now mandate higher corrosion resistance for all major civil concrete works, boosting the adoption rate of epoxy coated mesh systems.

2. Product Information & Technical Specifications

Product Name: Epoxy Coated Wire Mesh

Manufacturer: Ansheng Filter Screen Technologies

Website: https://www.anshengfilterscreen.com/epoxy-coated-wire-mesh.html

| Parameter | Epoxy Coated Wire Mesh | Standard Galvanized Mesh | Stainless Mesh |

|---|---|---|---|

| Wire Diameter | 1.0–6.0 mm | 0.8–5.0 mm | 0.8–5.0 mm |

| Mesh Opening | 25 × 25 – 150 × 150 mm | 50 × 50 – 150 × 150 mm | 25 × 25 – 100 × 100 mm |

| Coating Thickness | 60–120 μm (Epoxy) | 12–30 μm (Zinc) | N/A |

| Yield Strength | 450–580 MPa | 380–540 MPa | 520–650 MPa |

| Corrosion Resistance (ASTM B117, 1000h) | <5% Rust | 10–40% Rust | <2% Rust |

| Service Life (Concrete, Marine) | ≥50 years | 15–25 years | 30–60 years |

| Relevant Standards | ASTM A884, ISO 9001:2015 | ASTM A1064, ISO 1461 | ASTM A580/A580M, ISO 9001 |

Close-Up: Epoxy Coated Welded Wire Mesh—Micron-Precision Coating & Welded Grid

Close-Up: Epoxy Coated Welded Wire Mesh—Micron-Precision Coating & Welded Grid

3. Manufacturing Process Flow — Epoxy Coated Wire Mesh for Concrete

Certifications: ISO 9001:2015, ISO 14654 coating, ASTM A884.

4. Technical Indicators & Data Visualization

Below is a comprehensive dataset comparing epoxy coated wire mesh for concrete with other mesh types, alongside visualizations to facilitate engineering decisions.

5. Application Scenarios & Use Cases

Epoxy coated wire mesh for concrete is extensively deployed in scenarios requiring outstanding corrosion and mechanical performance. Typical sectors include:

- Underground Structures: Subway tunnels, sewer lines, potable water tanks

- Marine/Chemical Plants: Docks, wastewater treatment, petrochemical pumping stations

- Bridges & Highways: Maintenance-free deck slabs, parking areas, precast elements

- Energy/Electrochemical: Battery workshops, nuclear plant containment, power tunnels

Epoxy Mesh Forming Structural Grid in Utility Tunnel—No Corrosion Detected after 7 Years of Exposure.

Epoxy Mesh Forming Structural Grid in Utility Tunnel—No Corrosion Detected after 7 Years of Exposure.

(Verified by external audits, 2021, China Bridge Assoc.)

- Specification: Epoxy Coated Welded Wire Mesh, 5mm x 100x100mm grid, ISO 14654 epoxy layer

- Exposure: Acidic and high-moisture environment

- Test Results:

- No visible corrosion after 36 months

- Crack resistance increased by 66% over uncoated mesh

- Maintenance cycle extended to 12 years (vs. 3–5 years previously)

- ROI: Total lifecycle cost down by 38% (vs. stainless alternatives)

—Site QA Engineer, North European Metro Project, 2022

6. Manufacturer Comparison & Customization Options

| Supplier | Certification | Min. Mesh Size | Max. Panel Size | Epoxy Layer Thickness (μm) | Custom Shapes | Lead Time |

|---|---|---|---|---|---|---|

| Ansheng Filter Screen | ISO 9001:2015, ASTM A884 | 25 × 25 mm | 3.2 × 8 m | 60–120 | Yes (CNC cut, bent) | 10–18 days |

| WireMeshCo (DE) | ISO 14654 | 50 × 50 mm | 2 × 6 m | 60–90 | No | 17–23 days |

| AsiaMeshTech | ISO 9001 | 30 × 30 mm | 3 × 7 m | 50–110 | Yes | 14–21 days |

Custom Options: Upon request, manufacturers offer mesh with variable wire diameters, multi-color epoxy, CNC bent shapes, and integration with sensor/wiring for smart infrastructure projects.

7. Delivery, Quality Assurance & Support

- Standard lead time: 10–18 working days per container111 (based on mesh complexity and finish requirements).

- Warranty: 12–24 months against manufacturing and coating defects.

- Quality assurance: 100% batch inspection, ASTM and ISO standard adherence (with traceable QC report per batch).

- Support: Technical consultation on mesh sizing, specification calculation, and on-site installation support available.

- Third-party inspection: Support for SGS, BV, or customer-appointed agencies’ ex-factory audits.

8. Expert FAQ — Epoxy Mesh & Concrete Reinforcement (7 Key Questions)

9. Conclusion: EEAT Assessment & Industry Citations

The combination of rigorous manufacturing controls, ISO/ASTM standardization, and field-proven durability across geographies cements epoxy coated wire mesh for concrete as a cornerstone of modern infrastructure. As both smart cities and traditional sectors face rising technical complexity, selecting the right mesh partner—backed by data transparency, technical competence, and third-party certification—is mission-critical for achieving structural longevity, cost efficiency, and future-ready civil works.

- “Epoxy-Coated Reinforcement in Concrete Structures.” American Concrete Institute (ACI 222R-19)

- “Corrosion Resistance of Welded and Coated Steel Mesh in Submerged Conditions.” Cement and Concrete Composites, 2018

- “Performance of Epoxy-Coated Rebar and Mesh—A 10-Year Field Study.” TRB Transportation Research Forum, 2021

- “ISO 14654: Epoxy Powder Coating—Steel Wire Products.” ISO Standards Portal

- “Standard Specification for Epoxy-Coated Welded Wire Fabric—ASTM A884/A884M” ASTM International

- “Concrete Durability and Reinforcement Selection.” Structurae Industry Forums

Post time: Aug . 01, 2025 13:00