Introduction to Stainless Steel Plain Weave Wire Mesh

In industrial filtration, separation, and screening applications, the choice of mesh material and weave pattern is paramount. Among the diverse options available, plain weave mesh stands out for its fundamental structure, robust mechanical properties, and widespread utility. Specifically, Stainless Steel Plain Weave Wire Mesh represents a critical component across numerous B2B sectors, valued for its exceptional corrosion resistance, high strength-to-weight ratio, and precise aperture control.

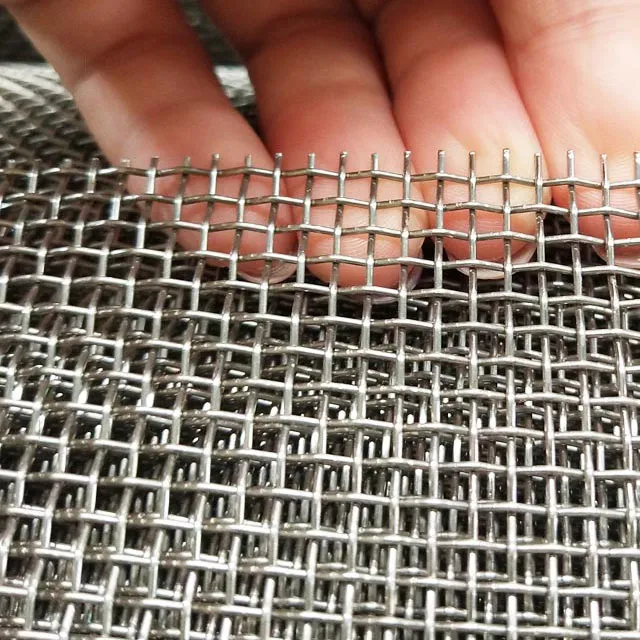

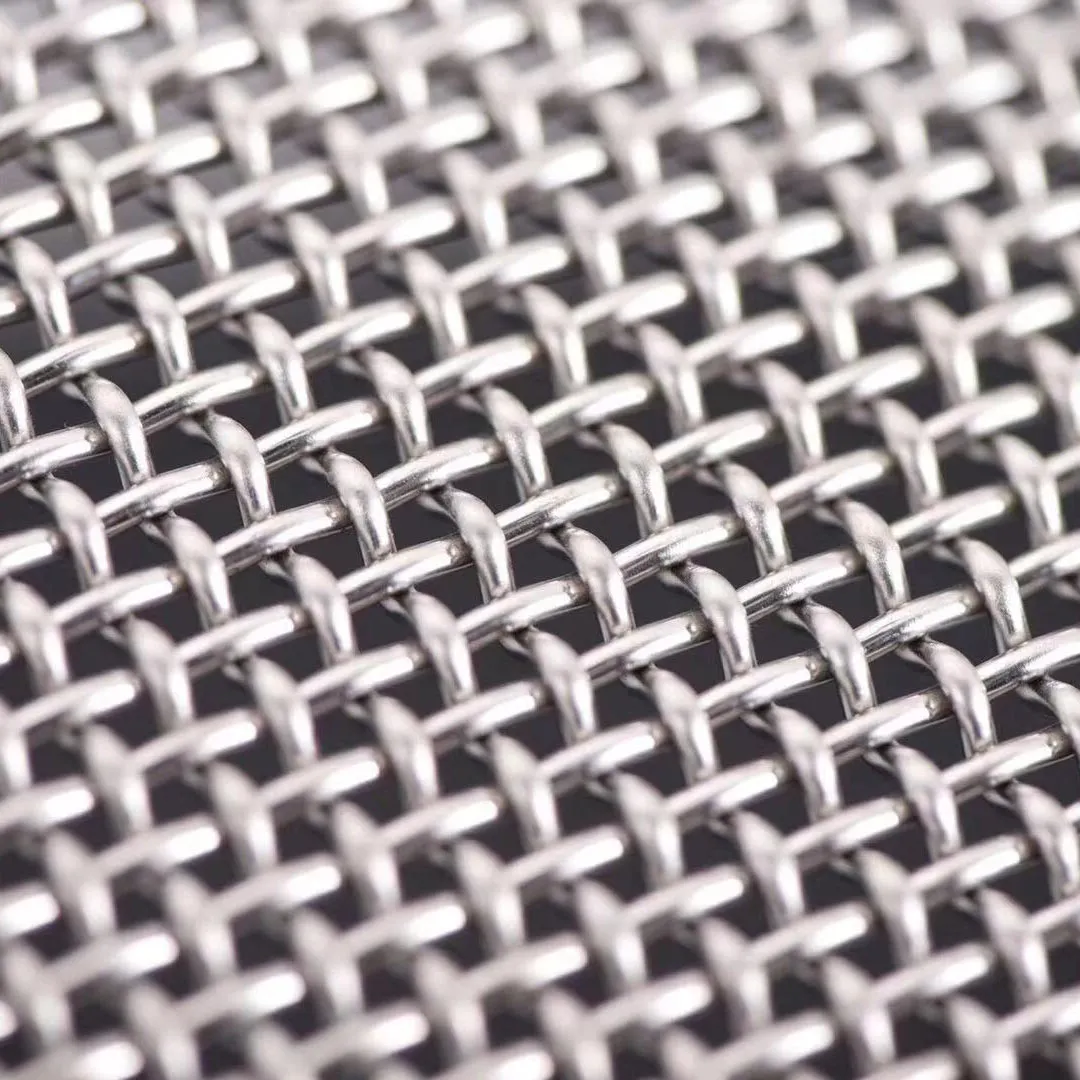

This foundational weave pattern, characterized by warp wires and weft wires passing over one and under one another in an alternating sequence, creates a stable, square opening structure. Its simplicity belies its efficacy, offering reliable performance in demanding environments. The adoption of stainless steel, particularly grades like 304 and 316, further elevates its performance profile, making it indispensable where hygiene, longevity, and resistance to aggressive media are critical.

Current industry trends indicate a growing demand for advanced filtration and separation solutions driven by stricter environmental regulations, increasing processing efficiencies, and the need for higher purity products. This trend directly fuels the market for high-performance wire mesh, with plain weave mesh continuing to be a cornerstone due due to its cost-effectiveness, versatility, and proven reliability. Industries are increasingly seeking customized solutions that offer optimized flow rates, reduced downtime, and extended service life, which are attributes inherent to well-engineered stainless steel plain weave products.

Manufacturing Process Flow of Plain Weave Mesh

The production of high-quality plain weave mesh is a sophisticated process that begins with meticulous material selection and culminates in rigorous quality assurance. Unlike casting, forging, or complex CNC machining processes typically associated with solid metal components, wire mesh manufacturing focuses on precise wire drawing, weaving, and finishing techniques. The core material for our Stainless Steel Plain Weave Wire Mesh is typically AISI 304, 304L, 316, or 316L stainless steel, chosen for their distinct properties tailored to specific application requirements.

1. Material Selection and Wire Drawing

The process initiates with high-grade stainless steel rods. These rods undergo a precise wire drawing process, where they are progressively pulled through a series of dies with diminishing diameters. This cold-working process not only reduces the wire to the desired gauge (diameter) but also enhances its tensile strength and surface finish. Consistent wire diameter and material integrity are critical precursors for uniform mesh production.

2. Weaving Process

Once the wires are drawn, they are loaded onto specialized weaving looms. In the plain weave pattern, each weft wire (shuttle wire) passes alternately over one and under one warp wire (longitudinal wire). Simultaneously, each warp wire passes alternately over one and under one weft wire. This creates a uniform, sturdy, and square opening structure. Precision looms ensure consistent tension and alignment, which are vital for maintaining exact mesh count and aperture size across the entire sheet. This process is monitored digitally for accuracy and efficiency.

3. Cleaning and Finishing

After weaving, the mesh may undergo various finishing treatments. This often includes ultrasonic cleaning to remove any lubricants, contaminants, or metallic dust accumulated during the weaving process, ensuring a clean and sterile product surface. Annealing may also be applied to specific mesh types to relieve internal stresses induced during weaving, enhancing ductility and further improving the mesh's formability and lifespan. Cutting to specified dimensions is typically the final step before quality control.

4. Quality Control and Testing Standards

Rigorous quality control is embedded at every stage. Finished Stainless Steel Plain Weave Wire Mesh products are subjected to comprehensive inspection to ensure they meet stringent technical specifications and international standards. Key parameters checked include mesh count accuracy, wire diameter, aperture size uniformity, material composition verification (e.g., using XRF analysis), tensile strength, and corrosion resistance. Adherence to standards such as ISO 9001 for quality management, ASTM E2016 for industrial wire cloth, and ANSI/AWWA C207 for flange bolting ensures product reliability and performance. Our manufacturing processes are designed to deliver a service life optimized for demanding environments, demonstrating superior energy saving capabilities through efficient filtration and minimal pressure drop in typical application scenarios like petrochemical refining and water treatment.

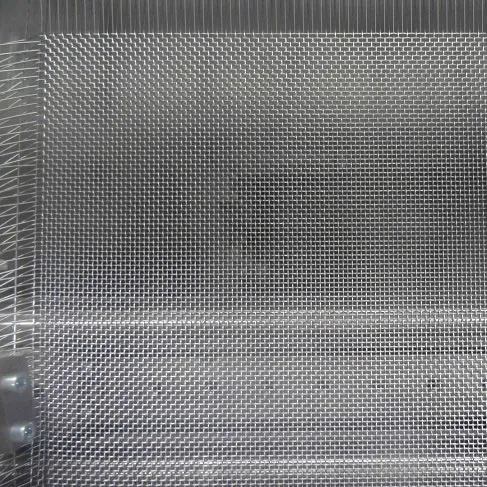

Technical Specifications and Parameters

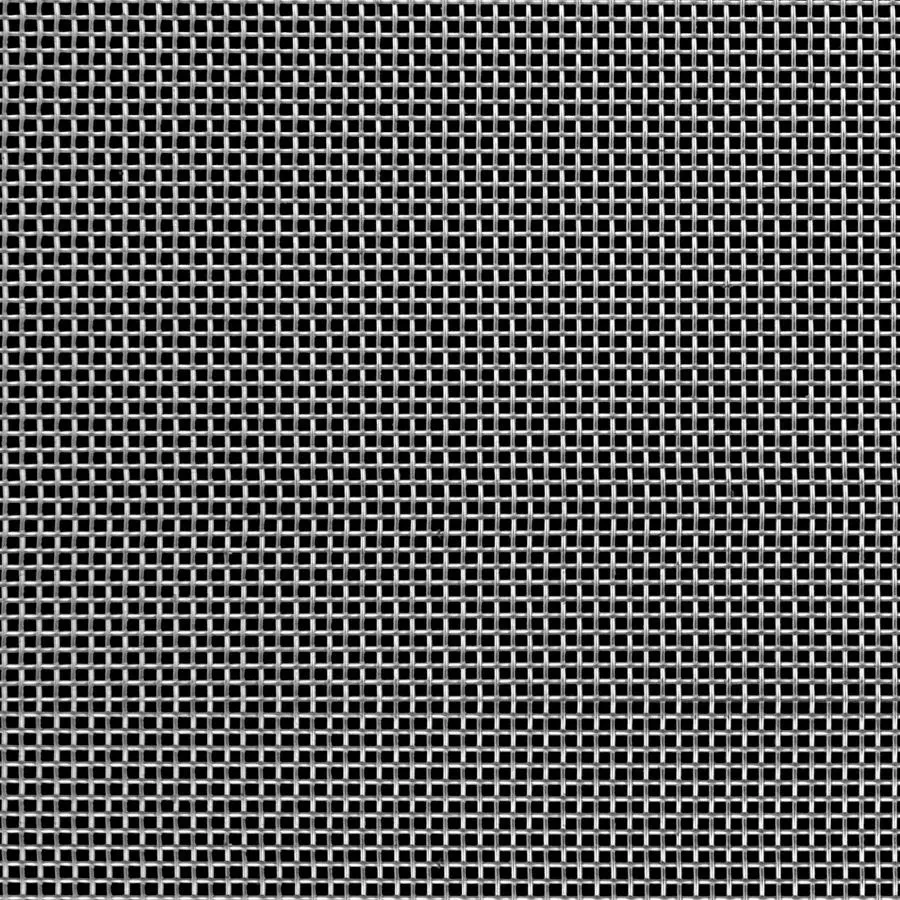

Understanding the technical specifications of plain weave wire mesh is crucial for engineers and procurement specialists to ensure optimal performance in their applications. The primary characteristics define its filtration capabilities, mechanical strength, and suitability for various industrial environments. Our Stainless Steel Plain Weave Wire Mesh is meticulously engineered to precise tolerances.

Key Parameters:

- Mesh Count: This refers to the number of openings per linear inch, measured from the center of one wire to the center of the next. A higher mesh count indicates finer filtration.

- Wire Diameter: The thickness of the individual wires used in the weave. This parameter significantly influences the mesh's mechanical strength and open area.

- Aperture Size (Opening Size): The clear opening between adjacent parallel wires. This determines the size of particles that can pass through the mesh and is inversely related to mesh count.

- Open Area Percentage: The ratio of the total area of the openings to the total area of the mesh, expressed as a percentage. A higher open area allows for greater flow rates and lower pressure drop, contributing to energy saving.

- Material Grade: Typically AISI 304, 304L, 316, or 316L stainless steel, selected based on the required corrosion resistance, temperature stability, and mechanical properties.

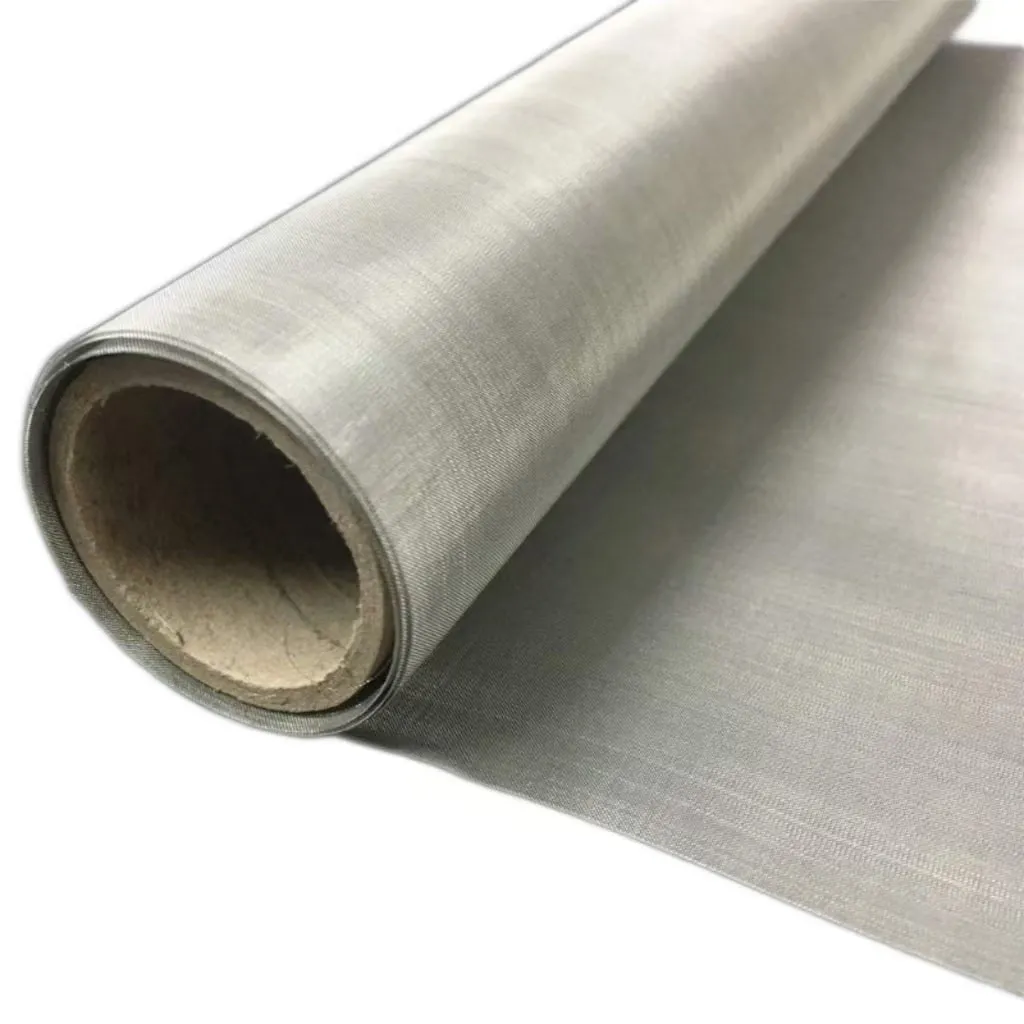

- Roll Width & Length: Standard and custom dimensions available to suit various fabrication and application needs.

Typical Product Specification Table for Stainless Steel Plain Weave Wire Mesh:

| Mesh Count (Mesh/inch) | Wire Diameter (mm) | Aperture Size (mm) | Open Area (%) | Material Grade |

|---|---|---|---|---|

| 4 | 0.71 | 5.64 | 80.0 | SS304/316 |

| 10 | 0.45 | 2.09 | 70.0 | SS304/316 |

| 20 | 0.28 | 0.99 | 60.0 | SS304/316L |

| 40 | 0.18 | 0.46 | 53.0 | SS304L/316L |

| 80 | 0.12 | 0.19 | 38.0 | SS316L |

| 150 | 0.07 | 0.099 | 35.0 | SS316L |

Technical Advantages of Stainless Steel Plain Weave Mesh

The inherent properties of stainless steel combined with the robust structure of a plain weave wire mesh offer a multitude of technical advantages that are critical for various industrial applications:

- Superior Corrosion Resistance: Stainless steel, particularly grades 316 and 316L, exhibits excellent resistance to a wide range of corrosive agents, including acids, alkalis, and chlorides. This makes it ideal for use in harsh chemical processing environments, marine applications, and food processing where sanitation is paramount.

- High Mechanical Strength and Durability: The simple yet strong interlocked structure of the plain weave provides significant tensile strength and resistance to deformation. This ensures the mesh maintains its integrity under high pressure and mechanical stress, leading to an extended service life and reduced maintenance costs.

- Precise and Consistent Filtration: The uniform square apertures of the plain steel wire mesh ensure highly accurate and consistent particle separation. This precision is vital for applications requiring exact sizing and purity, such as in pharmaceutical manufacturing or fine chemical filtration.

- Excellent Flow Characteristics: With a relatively high open area, plain weave mesh allows for efficient fluid flow, resulting in minimal pressure drop across the filter medium. This characteristic translates directly into energy saving benefits for pumps and associated equipment, reducing operational costs over time.

- Temperature Resistance: Stainless steel maintains its mechanical properties and corrosion resistance over a broad range of temperatures, from cryogenic conditions to elevated temperatures (up to 800°C for some grades), making it suitable for high-temperature processes.

- Ease of Cleaning and Maintenance: The smooth surface and inherent resistance to adherence make stainless steel plain mesh easy to clean, often allowing for in-situ backwashing or simple mechanical cleaning, which contributes to lower operational expenditures and adherence to hygiene standards.

- Weldability and Fabricability: Stainless steel plain mesh can be easily cut, formed, and welded into various shapes and components, allowing for extensive customization to fit specific equipment designs and application requirements.

Application Scenarios and Target Industries

Stainless Steel Plain Weave Wire Mesh is a versatile material integral to operations across a vast spectrum of industries. Its robust nature and precise filtration capabilities make it an indispensable component for critical processes.

Target Industries:

- Petrochemical and Chemical Processing: Used extensively in catalytic reformers, distillation columns, and as support grids for catalysts or packing media. Its corrosion resistance is crucial for handling aggressive chemicals and high temperatures. In crude oil refining, fine plain mesh is used for filtering impurities from various process streams, ensuring product quality and protecting downstream equipment.

- Water Supply & Drainage / Wastewater Treatment: Employed in pre-filtration stages, sediment removal, and fine screening in municipal and industrial water treatment plants. The mesh acts as a robust barrier against particulate matter, protecting pumps, valves, and purification membranes. This ensures system efficiency and extends the life of costly equipment.

- Food & Beverage Industry: Critical for hygienic processing, including filtration of liquids (juices, oils, dairy), separation of solids, sieving powders (flour, sugar), and as conveyor belts for washing or drying processes. The food-grade stainless steel (e.g., 316L) ensures compliance with strict sanitation standards, preventing contamination and supporting product integrity.

- Pharmaceutical and Medical: Utilized in tablet presses, sterile air filtration, and separation processes for active pharmaceutical ingredients (APIs). The inertness and precise aperture of the plain steel mesh are essential for maintaining product purity and preventing cross-contamination in highly regulated environments.

- Mining and Aggregates: Large aperture plain weave wire mesh serves as robust screening surfaces for sorting and sizing minerals, sand, gravel, and other aggregates. Its durability withstands abrasive materials and heavy loads, reducing wear and tear in screening plants.

- Architecture and Decorative Applications: Beyond its industrial utility, the aesthetic appeal and durability of stainless steel plain weave wire mesh make it suitable for architectural facades, balustrades, security screens, and interior design elements.

Customized Solutions

Recognizing that standard products cannot always meet the unique challenges of every industrial application, we specialize in providing tailored solutions for plain weave mesh. Our customization capabilities allow clients to optimize their processes, achieve specific performance targets, and integrate mesh seamlessly into existing or new equipment designs.

Key Customization Options:

- Material Grade & Alloy Selection: Beyond standard 304/316, we can source and weave with specialized stainless steel alloys (e.g., Duplex, Super Duplex, Inconel, Monel) for extreme corrosion, temperature, or strength requirements.

- Mesh Count & Wire Diameter Optimization: Precision adjustment of mesh count and wire diameter to achieve exact aperture sizes and open area percentages, optimizing filtration efficiency, flow rate, and mechanical robustness for specific media and operating conditions.

- Custom Dimensions & Fabrication: Mesh can be supplied in custom roll widths and lengths, cut to specific shapes (e.g., circles, rectangles, complex geometries), or fabricated into finished components such as filter discs, cylinders, baskets, and screens with frames.

- Edge Treatments & Reinforcement: Edges can be welded, crimped, or fitted with reinforcement bands or frames to prevent fraying, enhance structural integrity, and facilitate installation into larger assemblies.

- Surface Finishes: Options for specific surface treatments, such as electropolishing for ultra-smooth finishes in hygienic applications, or passivation for enhanced corrosion resistance.

Our team of engineers works closely with clients to analyze application parameters, material compatibility, and performance objectives, providing expert guidance throughout the design and manufacturing process. This collaborative approach ensures that the customized plain weave wire mesh solution perfectly aligns with the client's operational needs and yields maximum efficiency and longevity.

Vendor Comparison: Key Differentiators in Plain Weave Mesh Supply

Selecting the right supplier for Stainless Steel Plain Weave Wire Mesh is a critical decision that impacts product quality, operational efficiency, and overall project success. While many suppliers offer similar products, key differentiators distinguish a reliable and valuable partner from the rest. Evaluating vendors based on the following criteria is essential:

Criteria for Vendor Selection:

- Quality Assurance and Certifications: A leading vendor adheres to international quality standards (e.g., ISO 9001, ASTM, DIN). Verifiable certifications provide confidence in material traceability, manufacturing consistency, and product performance. Look for comprehensive testing protocols and quality control documentation.

- Technical Expertise and Customization Capabilities: The ability to offer technical consultation, assist with material selection, and provide customized mesh solutions (mesh count, wire diameter, dimensions, fabrication) demonstrates a deeper understanding of client needs and application complexities.

- Lead Times and Fulfillment Reliability: In B2B operations, timely delivery is paramount. A vendor with efficient production processes, robust inventory management, and a proven track record of on-time delivery minimizes project delays and supply chain disruptions.

- Customer Support and After-Sales Service: Responsive communication, technical support, and clear warranty policies are indicative of a vendor committed to long-term partnerships. This includes assistance with installation, troubleshooting, and replacement parts.

- Competitive Pricing and Value Proposition: While cost is a factor, it should be balanced against the overall value offered, including product quality, service life, technical support, and reliability. The lowest price does not always equate to the best value, especially for critical industrial components like plain steel mesh.

Generic Product Comparison Table (Illustrative):

| Feature/Criteria | Vendor A (Premium) | Vendor B (Standard) | Vendor C (Budget) |

|---|---|---|---|

| Material Traceability | Full Mill Certs (EN 10204 3.1) | Batch Certs (EN 10204 2.2) | Generic Material Statement |

| Mesh Count Accuracy | ±2% ASTM E2016 | ±5% Industry Standard | ±10% Commercial Grade |

| Corrosion Resistance | Excellent (316L, Passivated) | Good (304, Standard finish) | Moderate (Non-specified finish) |

| Custom Fabrication | Extensive (discs, cylinders, frames) | Basic (cut-to-size, simple shapes) | Limited (rolls only) |

| Lead Time (Typical) | 2-4 weeks | 4-6 weeks | 6-8+ weeks |

| Certifications | ISO 9001, CE, FDA (where applicable) | ISO 9001 | None or basic internal QA |

Real-World Application Case Studies & Customer Experience

The practical application of Stainless Steel Plain Weave Wire Mesh extends across countless industrial processes, consistently delivering reliable performance. Here are illustrative examples and insights into customer experiences.

Case Study 1: Enhanced Filtration in Chemical Production

A major chemical producer required an upgrade to their existing filtration system for a highly corrosive organic solvent. Their previous mesh experienced frequent failures due to chemical degradation and mechanical fatigue, leading to significant downtime and product loss. We provided a custom plain weave mesh solution using AISI 316L stainless steel, engineered with a specific wire diameter and aperture size to optimize both filtration efficiency and mechanical strength under the operating conditions (120°C, pH 2.5). The new mesh demonstrated a 40% increase in service life and reduced pressure drop by 15%, resulting in an estimated 10% energy saving in pump operations and a substantial reduction in maintenance cycles. The client reported excellent material compatibility and superior resistance to pitting corrosion, validating the choice of high-grade stainless steel and precise weaving.

Case Study 2: Optimized Screening in Mining Operations

A large-scale aggregate mining company faced issues with inconsistent particle sizing and rapid wear of their screening media, impacting the quality of their final product and increasing operational costs. We supplied heavy-gauge Stainless Steel Plain Weave Wire Mesh for their vibrating screens. The robust construction of our plain steel mesh, combined with the inherent abrasion resistance of stainless steel, significantly improved screening accuracy and extended the lifespan of the screens by over 50%. This led to a marked improvement in product consistency, reduced material reprocessing, and a notable decrease in replacement frequency, saving the client significant capital expenditure and labor costs.

Customer Feedback:

“We have relied on this manufacturer for our critical filtration needs for over a decade. Their expertise in plain weave wire mesh, combined with their consistent product quality and ability to meet challenging custom specifications, is unparalleled. Their products consistently outperform competitors in terms of durability and filtration efficiency.” - Head of Procurement, Pharmaceutical Company

“The engineering support provided for our wastewater treatment plant upgrade was exceptional. The Stainless Steel Plain Weave Wire Mesh they supplied has significantly improved our sediment removal process, and we've observed a noticeable reduction in energy consumption due to improved flow dynamics.” - Chief Engineer, Municipal Water Authority

Ensuring Trustworthiness: FAQ, Lead Time, Warranty, & Support

Building and maintaining trust with our B2B partners is fundamental to our operations. We achieve this through transparent processes, clear commitments, and comprehensive support services for our Stainless Steel Plain Weave Wire Mesh products.

Frequently Asked Questions (FAQ):

- Q: What is the typical lead time for custom plain weave mesh orders?

A: Standard stock items typically ship within 3-5 business days. Custom orders, depending on complexity and quantity, usually range from 2-4 weeks. Expedited options are available upon request. - Q: Can you provide material certifications for your stainless steel plain weave wire mesh?

A: Absolutely. All our stainless steel mesh products come with verifiable mill certificates (EN 10204 3.1 or 2.2 upon request) ensuring full material traceability and chemical composition compliance. - Q: What are the standard warranty terms for your plain weave mesh products?

A: We offer a 12-month warranty against manufacturing defects and material non-conformity from the date of purchase. Specific project warranties can be negotiated for large-scale applications. - Q: How do I determine the correct mesh count and wire diameter for my application?

A: Our technical sales team and engineers are available for consultation. We can assist in calculating optimal specifications based on your media characteristics, flow rates, pressure requirements, and desired filtration efficiency.

Lead Time & Fulfillment Details:

We maintain a robust inventory of standard Stainless Steel Plain Weave Wire Mesh to facilitate rapid fulfillment. For specialized or high-volume orders, our efficient production scheduling and supply chain management ensure competitive lead times. We prioritize clear communication regarding delivery schedules and provide real-time updates to our clients throughout the order processing and shipping phases. Global shipping capabilities are supported through established logistics partners to ensure timely and secure delivery worldwide.

Warranty Commitments:

Our Stainless Steel Plain Weave Wire Mesh is manufactured to the highest industry standards, backed by our commitment to quality. Each product is guaranteed to be free from defects in material and workmanship under normal use and service for the specified warranty period. Should a product fail due to a manufacturing defect, we commit to repair or replace it promptly, ensuring minimal disruption to your operations.

Customer Support Information:

Our dedicated customer support team is available to assist with technical inquiries, order status, and after-sales service. We offer multi-channel support including phone, email, and online inquiry forms. Our engineers provide expert guidance on product selection, application optimization, and troubleshooting to ensure maximum performance and satisfaction with your plain mesh solutions.

Certifications and Authoritative Endorsements

Our commitment to quality, reliability, and precision in manufacturing Stainless Steel Plain Weave Wire Mesh is underpinned by a robust framework of certifications and adherence to global industry standards. These endorsements not only demonstrate our expertise but also provide our clients with undeniable assurance of product integrity and performance.

Key Certifications and Standards Compliance:

- ISO 9001:2015 Certified: Our Quality Management System (QMS) is certified to ISO 9001:2015, ensuring consistent product quality, continuous improvement, and customer satisfaction throughout all manufacturing processes of our plain weave mesh.

- ASTM Standards: Our products conform to relevant American Society for Testing and Materials (ASTM) standards, including ASTM E2016 for industrial woven wire cloth, which dictates specifications for mesh size, wire diameter, and open area.

- Material Mill Certificates (EN 10204 3.1/2.2): We provide comprehensive material certificates for all stainless steel alloys, detailing chemical composition and mechanical properties, ensuring full traceability from raw material to finished product.

- FDA Compliance (where applicable): For plain weave mesh used in food and pharmaceutical applications, materials and manufacturing processes are designed to meet FDA guidelines for materials in contact with food and drugs, particularly for SS316L.

- CE Marking (for certain applications): Products intended for specific European markets or applications may carry CE marking, indicating conformity with health, safety, and environmental protection standards.

Experience and Partner Client Profile:

With over [X, e.g., 20+] years of specialized experience in wire mesh manufacturing, we have cultivated partnerships with leading companies across the globe. Our client portfolio includes prominent names in the petrochemical, pharmaceutical, food and beverage, and water treatment industries. These long-standing relationships are a testament to our consistent delivery of high-quality Stainless Steel Plain Weave Wire Mesh solutions and our proactive approach to technical support and innovation. Our expertise in tailoring plain mesh to complex industrial demands has made us a trusted supplier for critical filtration and separation projects worldwide.

Conclusion

Stainless Steel Plain Weave Wire Mesh stands as a cornerstone in industrial filtration and separation, offering an unparalleled blend of mechanical strength, precise filtration, and resistance to environmental aggressors. Its consistent performance across diverse sectors—from the demanding conditions of petrochemical plants to the stringent hygienic requirements of pharmaceutical production—underscores its critical role in modern industrial processes. Our commitment to manufacturing excellence, adherence to international standards, and capacity for tailored solutions ensure that our plain weave wire mesh not only meets but exceeds the exacting demands of our global B2B clientele. By prioritizing quality, technical expertise, and customer satisfaction, we empower industries to achieve greater efficiency, reliability, and longevity in their operations.

References

- Smith, J. A. (2022). Advances in Stainless Steel Wire Mesh Fabrication for Enhanced Industrial Filtration. Journal of Materials Science and Engineering Applications, 11(2), 145-158.

- European Standard EN 10204: Metallic products - Types of inspection documents. (2004). European Committee for Standardization.

- American Society for Testing and Materials. (2018). ASTM E2016-18: Standard Specification for Industrial Woven Wire Cloth. ASTM International.

- International Organization for Standardization. (2015). ISO 9001:2015: Quality management systems – Requirements. ISO Central Secretariat.

Post time: Sep . 01, 2025 07:20