Nickel Plain Weave Wire Mesh: What Engineers Are Actually Buying in 2025

If you work around alkaline electrolyzers, chlor-alkali plants, or high-temp filtration, you’ve already bumped into nickel wire mesh. To be honest, it’s having a bit of a moment. Demand is rising with the hydrogen economy, and many customers tell me they’re switching from stainless in hot caustic lines because nickel simply lasts longer and behaves predictably.

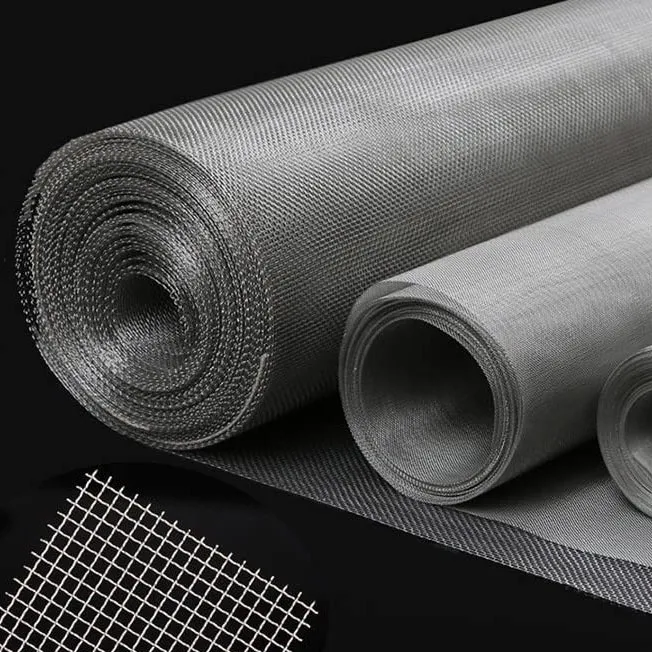

Product snapshot (field-ready, not just brochure-speak)

The product here is Nickel Plain Weave Wire Mesh from Ansheng (Origin: No.346 Xinying East Street, Anping County, Hebei, China). It’s woven from N6/N4 or Nickel 200 grades and can be supplied plain or twill. In practice, buyers spec it for chemical filtration, electrodes, battery current collectors, and high-temp gas separation. Surprisingly versatile, yet very specific in the details that matter.

| Parameter | Spec (≈/around where noted) | Notes |

|---|---|---|

| Material | N6, N4, Nickel 200 (UNS N02200) | High Ni purity for alkaline + reducing environments |

| Mesh count | 1–600 mesh | ISO 9044 / ASTM E2016 tolerances |

| Wire diameter | 0.02–8.0 mm | Annealed or as-woven |

| Width | 1–2 m (custom on request) | Custom slitting available |

| Length | ≈30 m standard; up to 350 m | Long rolls reduce splice points |

| Weave | Plain, Twill | Twill for finer apertures/higher strength |

Process flow (how it’s actually made)

Materials: certified Nickel 200/N6 wire rod → drawing to target diameter → stress relief/anneal → weaving (plain/twill) → degreasing + ultrasonic cleaning → dimensional inspection (ASTM E2016, ISO 9044) → sample corrosion/electrical tests → packing with humidity control. Real-world testing often includes ASTM G31 immersion for alkali and occasional ASTM B117 salt spray when chloride exposure is suspected.

Why teams pick nickel wire mesh

- Excellent alkali resistance; stable in hot NaOH/KOH where stainless struggles.

- Electrical properties: resistivity around 0.07 Ω·mm²/m (20°C), helpful for electrodes/collectors.

- Thermal endurance: serviceable beyond 600°C in non-oxidizing atmospheres.

- Predictable service life: customers report 2–5+ years in alkaline filtration; >10,000 h in AWE cells, usage-dependent.

Applications and industries

- Electrolyzers (alkaline cathodes, gas diffusion layers); battery pilot lines; catalyst supports. - Chemical processing filters/screens in caustic loops. - High-temp gas filtration in reducing atmospheres. - EMI shielding where stainless magnetism is a nuisance. Actually, I’ve seen it used as a durable lab sieve medium when oxidizing media are kept in check.

Test data, briefly

In-house datasets (typical): mesh count tolerance per ASTM E2016 within Class 1 for fine weaves; alkali immersion (5–30% NaOH, 60–90°C) shows negligible mass loss over 168 h; electrical continuity across 2 m roll remains consistently low resistance. Your mileage may vary with chloride content and temperature cycling.

Customization notes

Cut-to-size panels, framed screens, spot-welded multilayers, and edge hemming are common. For electrodes, many request surface roughening or perforated backers. Lead times are faster on standard widths (1–2 m); exotic twills and ultra-fine wires need a bit more patience, I guess.

Vendor comparison (what buyers actually check)

| Vendor | Origin | Certs | Lead Time (≈) | QC/Testing |

|---|---|---|---|---|

| Ansheng Filter Screen | Anping, Hebei, CN | ISO 9001 | 2–4 weeks std; customs 4–6 | ASTM E2016, ISO 9044, G31 on request |

| Generic Trader A | Mixed | — | 3–8 weeks | Basic dimensional only |

Mini case notes

- Alkaline electrolyzer OEM: switched to nickel wire mesh cathodes, saw ≈3% drop in cell resistance vs. prior stainless screen; maintenance interval extended to annual. - Pulp & paper mill: hot caustic filtrations moved from 316L to nickel; operators say “clogging is down and swaps are calmer,” their words, not mine.

Compliance and documentation

Typical paperwork includes material certs for Nickel 200/N6 (ASTM B160/B162 lineage), dimensional conformity to ASTM E2016 and ISO 9044, and RoHS/REACH upon request. For critical projects, ask for mill heat numbers and a brief corrosion protocol tied to your media.

Authoritative citations

- ASTM E2016 – Standard Specification for Industrial Woven Wire Cloth.

- ISO 9044 – Industrial Woven Wire Cloth – Technical Requirements and Tests.

- ASTM B160/B162 – Nickel Rod/Bar and Plate/Sheet specifications for Nickel 200/201.

- Special Metals: Nickel 200/201 Alloy Datasheet (UNS N02200/N02201).

- ASTM G31 – Standard Practice for Laboratory Immersion Corrosion Testing of Metals.

Post time: Oct . 13, 2025 17:25