galvanized wire mesh, galvanized wire mesh panels, galvanized wire mesh for sale, gi wire mesh, galvanized screen is a key solution in the manufacturing industry, specifically within Fabricated metal products and Manufacturing of wire mesh and silk products. This article explores how Anping County Ansheng Wire Meshes Product Co., Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- galvanized wire mesh, galvanized wire mesh panels, galvanized wire mesh for sale, gi wire mesh, galvanized screen Overview

- Benefits & Use Cases of galvanized wire mesh, galvanized wire mesh panels, galvanized wire mesh for sale, gi wire mesh, galvanized screen in Manufacturing of wire mesh and silk products

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on galvanized wire mesh, galvanized wire mesh panels, galvanized wire mesh for sale, gi wire mesh, galvanized screen from Anping County Ansheng Wire Meshes Product Co., Ltd.

galvanized wire mesh, galvanized wire mesh panels, galvanized wire mesh for sale, gi wire mesh, galvanized screen Overview

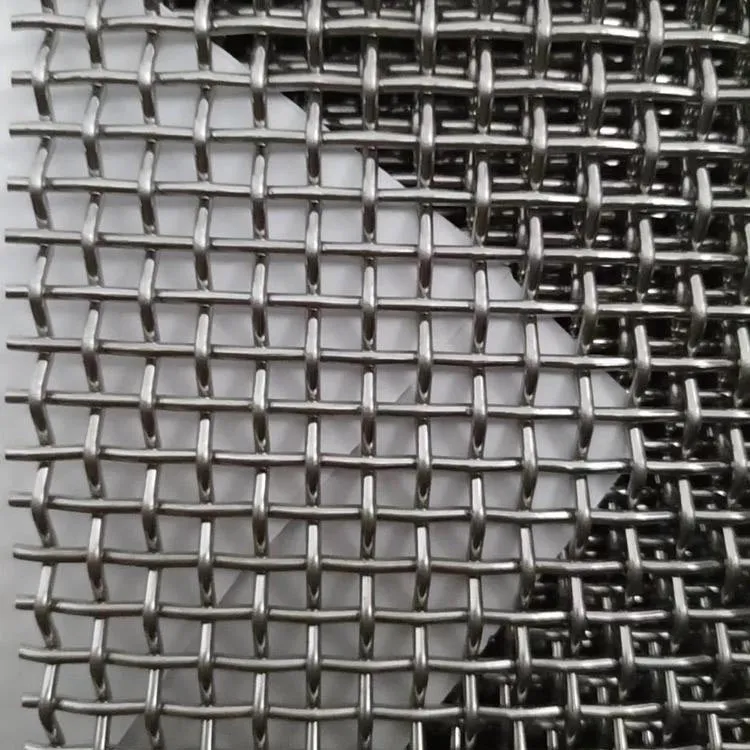

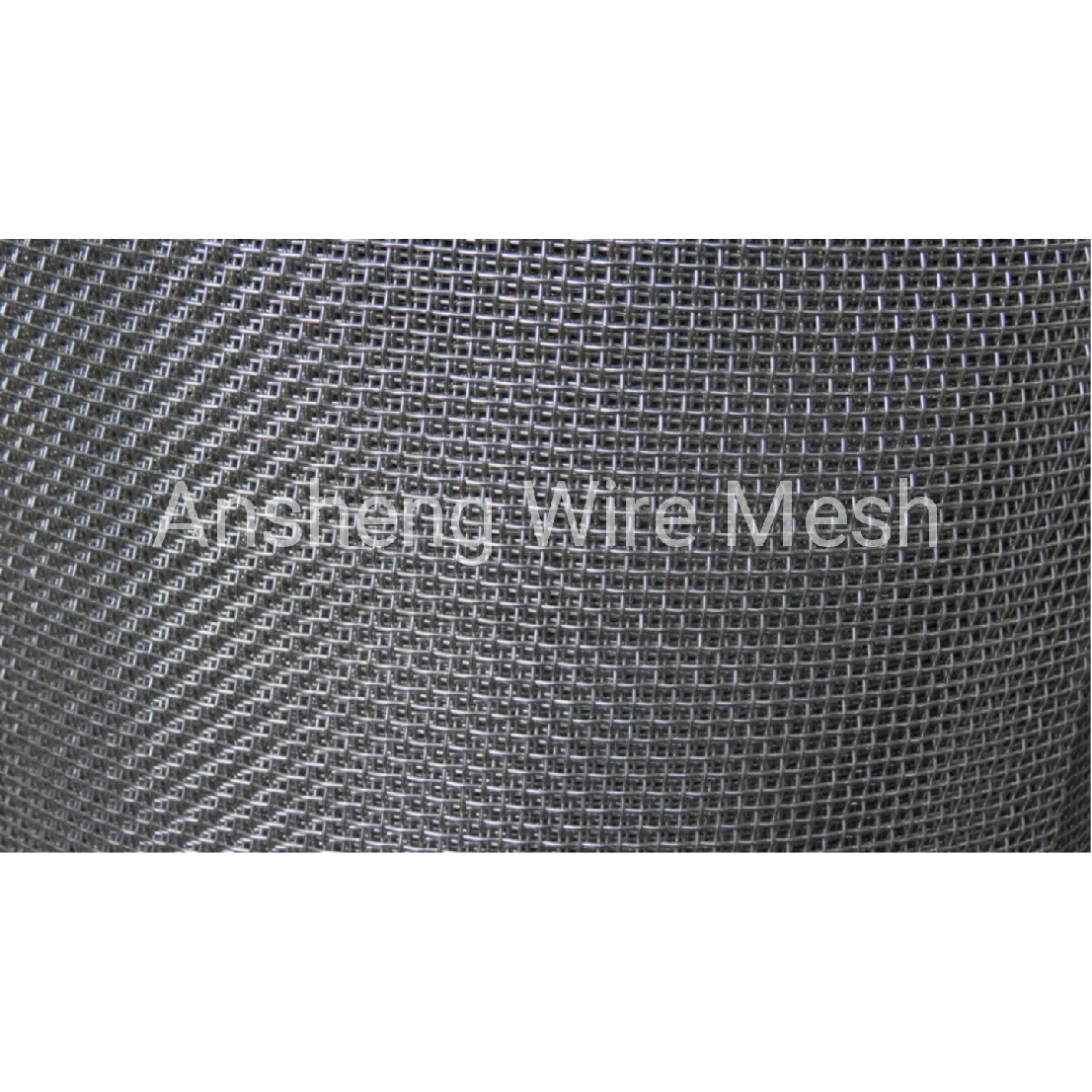

Galvanized wire mesh—also known as gi wire mesh (galvanized iron wire mesh) or galvanized screen—is steel mesh protected by a zinc coating to resist corrosion and wear. For B2B decision makers in fabricated metal products, it delivers a dependable balance of strength, formability, and longevity across factory safety, filtration, and architectural applications. Anping County Ansheng Wire Meshes Product Co., Ltd. manufactures galvanized wire mesh in rolls and in rigid galvanized wire mesh panels to meet high-volume OEM and project needs.

Technical options typically include hot-dip galvanizing for maximum corrosion resistance and electro-galvanizing for cost efficiency and smooth finish. Common specifications offered by Ansheng include mesh apertures from coarse to fine (e.g., 2–200 mesh), wire diameters from light to heavy gauge for structural or screening tasks, and panel formats with clean, trimmed edges for fast installation. Welded and woven constructions are both available to match load, airflow, and filtration targets. In a recent equipment-guarding supply program, a customer standardized on Ansheng galvanized panels to improve line safety and reduce repainting and rework during maintenance cycles.

Benefits & Use Cases of galvanized wire mesh, galvanized wire mesh panels, galvanized wire mesh for sale, gi wire mesh, galvanized screen in Manufacturing of wire mesh and silk products

Across the Manufacturing of wire mesh and silk products segment, galvanized wire mesh serves as a versatile input and finished component. Typical use cases include machine guards, conveyor enclosures, storage cages, racking, partition walls, fencing, ventilation and HVAC pre-filters, plaster/stucco support, and protective screens for equipment and glazing. Galvanized wire mesh panels accelerate installation on production floors, while rolls offer flexibility for forming, cutting, and integration into downstream assemblies.

Key advantages for industrial buyers include dependable corrosion resistance, consistent mesh geometry for precise airflow or particle sizing, strong weld integrity for load-bearing frames, and excellent paint/powder adhesion where color coding is required. gi wire mesh is also easy to fabricate—shearing, bending, and fastening with standard shop tools—lowering integration costs. Anping County Ansheng Wire Meshes Product Co., Ltd., located in China’s renowned Anping wire mesh hub, leverages specialized welding lines, tight dimensional controls, and rigorous inspection to deliver repeatable quality for OEMs, EPCs, and fabricators worldwide.

Cost, Maintenance & User Experience

Total cost of ownership for galvanized screen products depends on exposure, mechanical load, and finish selection. Hot-dip galvanized meshes generally offer longer service life in outdoor or humid settings, reducing replacement frequency and downtime. Electro-galvanized options provide a smooth, uniform coating at attractive pricing for indoor uses. For purchasing teams, standardized sizes of galvanized wire mesh panels can cut labor, while bulk rolls minimize material waste for custom parts. Many customers in the fabricated metal products sector report fewer coatings touch-ups and faster assembly compared with uncoated steel or ad-hoc finishing workflows.

Maintenance is straightforward: keep surfaces clean from corrosive residues, avoid aggressive acids/alkalis, and touch up cut edges with zinc-rich coatings when required. Routine inspections help ensure guards, cages, and filters maintain structural integrity and compliance with safety standards. Anping’s packaging and labeling practices support efficient receiving and traceability, and samples can be supplied for validation prior to volume orders—improving ROI by aligning specifications with real-world performance.

Sustainability & Market Trends in manufacturing

As manufacturers advance sustainability goals, galvanized wire mesh contributes through durability, recyclability, and material efficiency. Steel and zinc are both widely recyclable, and long-life coatings reduce the environmental impact of frequent replacements. Many buyers also look to align with evolving regulatory frameworks and certifications. Anping County Ansheng Wire Meshes Product Co., Ltd. emphasizes responsible sourcing, quality management, and process controls to help customers meet corporate and market requirements.

Market demand for galvanized wire mesh is growing in industrial safety, warehousing, agritech, infrastructure, and building systems. Trends include greater emphasis on modular guarding systems, standardized panel formats for rapid deployment, and fine-mesh galvanized screen for air and water pre-filtration. With agile production and custom fabrication capabilities, Anping supports short lead times, special apertures, and tailored finishes—helping B2B buyers reduce waste, enhance safety, and improve total lifecycle performance.

Conclusion on galvanized wire mesh, galvanized wire mesh panels, galvanized wire mesh for sale, gi wire mesh, galvanized screen from Anping County Ansheng Wire Meshes Product Co., Ltd.

For decision makers in manufacturing and fabricated metal products, galvanized wire mesh delivers an optimal mix of strength, corrosion resistance, and fabrication ease—whether specified as rolls, cut parts, or galvanized wire mesh panels. Backed by the expertise of Anping County Ansheng Wire Meshes Product Co., Ltd., you gain consistent quality, responsive service, and scalable production for projects of any size.

Contact us: email: sales@anshengwiremesh.com

Visit our website: https://www.anshengfilterscreen.com

Explore product details and specifications: Galvanized Wire Mesh

Post time: Oct . 14, 2025 06:25