Multi-Layer Mesh With Welding Spots: Advanced Solutions for Industrial Applications

At Anping County Ansheng Wire Meshes Product Co., Ltd., we specialize in providing high-quality industrial mesh solutions that meet the evolving demands of modern manufacturing. Our Multi-Layer Mesh With Welding Spots is a prime example of our commitment to innovation and precision engineering. Designed for durability, efficiency, and versatility, this product is engineered to deliver exceptional performance across a wide range of applications.

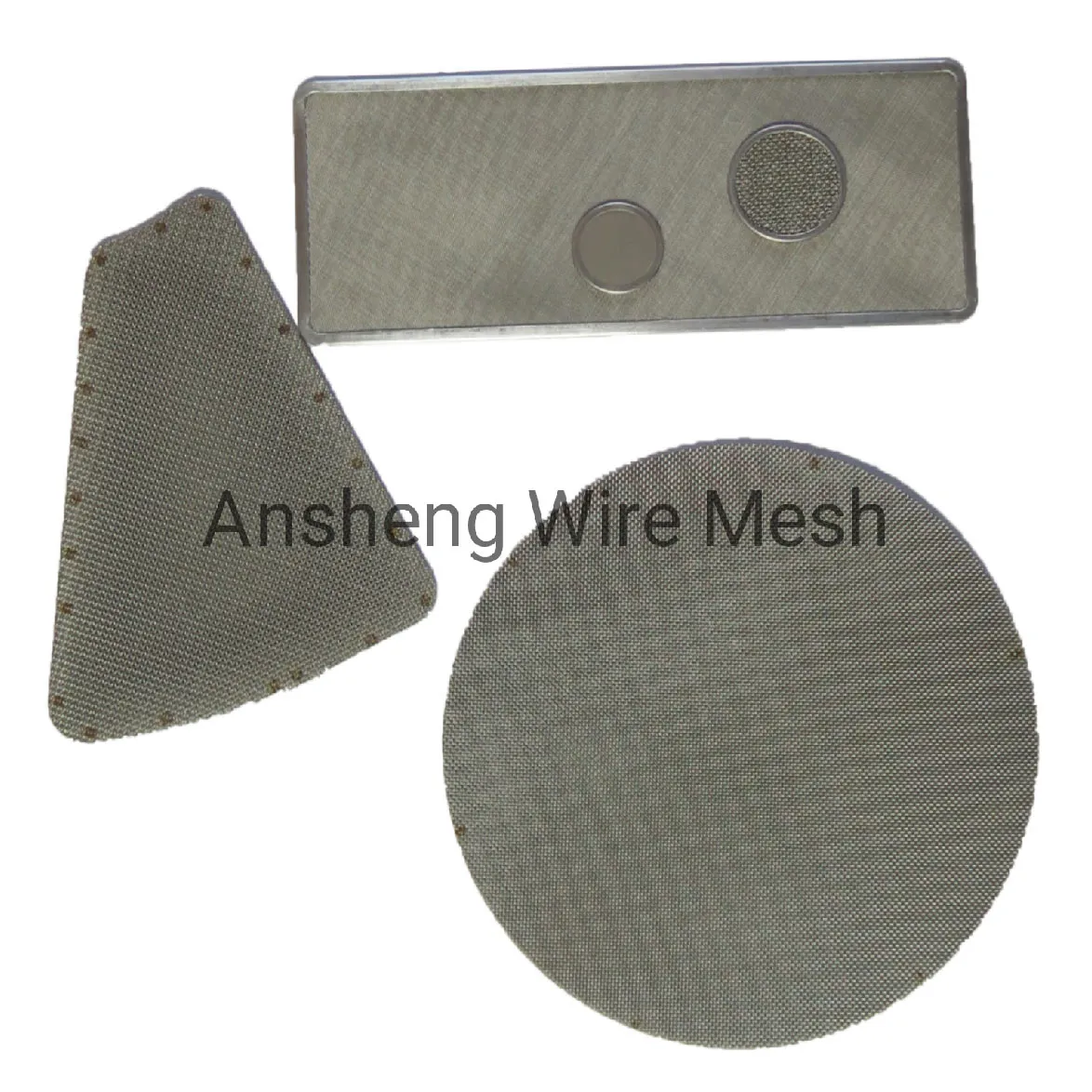

Product Overview: Multi-Layer Mesh With Welding Spots

The Multi-Layer Mesh With Welding Spots is a specialized industrial mesh designed to combine structural integrity with functional adaptability. This product features multiple layers of wire mesh interconnected by strategically placed welding spots, ensuring robustness while maintaining flexibility. The welding spots reinforce the mesh's durability, making it ideal for applications that require both strength and precision.

Key Features and Technical Specifications

- Multi-Layer Construction: The mesh is composed of multiple layers of wire mesh, providing enhanced filtration, support, and resistance to deformation.

- Welding Spots: These spots are strategically welded to strengthen the mesh structure, preventing slippage or separation under heavy loads.

- Customizable Sizes: Available in various dimensions, including 125mm, 150mm, and 225mm mesh sanding discs, to suit specific industrial requirements.

- Durable Materials: Crafted from high-quality wire materials, ensuring resistance to corrosion, wear, and tear.

- Smooth Surface: The mesh offers a smooth, even surface for consistent performance in applications such as sanding, filtering, and screening.

Industrial Applications of Multi-Layer Mesh With Welding Spots

The versatility of the Multi-Layer Mesh With Welding Spots makes it a valuable asset in numerous industries. Some of the primary applications include:

- Industrial Filtration: Used in filtration systems to separate solids from liquids or gases, ensuring efficient and reliable operation.

- Surface Preparation: Ideal for sanding and surface treatment applications, where the mesh's welding spots provide stability and precision.

- Screening and Sieving: The multi-layer design allows for accurate particle separation in industries such as mining, agriculture, and pharmaceuticals.

- Automotive and Aerospace: Applied in manufacturing processes that require durable, high-precision mesh components.

- Construction and Manufacturing: Utilized in tools and equipment where strength and durability are critical.

Why Choose Anping County Ansheng Wire Meshes Product Co., Ltd.?

Anping County Ansheng Wire Meshes Product Co., Ltd. has established itself as a leading manufacturer of wire mesh products in China. With decades of experience, we combine advanced technology with meticulous craftsmanship to deliver products that meet the highest standards of quality and performance.

Our Commitment to Quality and Innovation

At Anping County Ansheng, we prioritize innovation and continuous improvement. Our state-of-the-art manufacturing facilities and rigorous quality control processes ensure that every product meets exacting specifications. We also offer customized solutions to address the unique needs of our clients, ensuring optimal performance and cost-effectiveness.

Customer Testimonials and Success Stories

Our customers consistently praise the reliability and performance of our Multi-Layer Mesh With Welding Spots. For example, a leading automotive manufacturer reported a 20% increase in production efficiency after integrating our mesh into their surface preparation systems. Another client in the pharmaceutical industry highlighted the mesh's precision in particle separation, which significantly improved their product quality.

Installation and Usage Guidelines

Proper installation and usage are essential to maximize the performance of the Multi-Layer Mesh With Welding Spots. Our team provides detailed guidelines to ensure seamless integration into your existing systems. For specific applications such as 125mm mesh sanding discs or 225mm mesh sanding discs, we recommend consulting our technical support team for tailored recommendations.

Environmental and Safety Compliance

All our products adhere to strict environmental and safety standards. The Multi-Layer Mesh With Welding Spots is manufactured using eco-friendly materials and processes, ensuring minimal environmental impact. Additionally, the mesh is designed to meet safety regulations, providing a secure and reliable solution for industrial use.

Ordering and Logistics

For bulk orders, we offer competitive pricing and efficient logistics solutions. Our packaging ensures the safe transportation of the mesh, preserving its integrity during shipping. Please contact our sales team for detailed information on ordering, pricing, and delivery timelines.

Customer Support and After-Sales Service

We are committed to providing exceptional customer support. Our dedicated team is available to address any inquiries, provide technical assistance, and offer product customization services. Whether you need guidance on installation or have specific requirements, we are here to help.

Contact Us for More Information

For further details about the Multi-Layer Mesh With Welding Spots or to discuss your specific needs, please visit our website at Anping County Ansheng Wire Meshes Product Co., Ltd. or contact us directly via phone or email.

Frequently Asked Questions (FAQ)

Q: What are the standard sizes available for the Multi-Layer Mesh With Welding Spots?

A: We offer standard sizes including 125mm, 150mm, and 225mm mesh sanding discs, with custom options available upon request.

Q: Can the mesh be used in high-temperature environments?

A: Yes, the mesh is designed to withstand high temperatures and maintain structural integrity under demanding conditions.

Q: How long does it take to receive an order?

A: Delivery times vary depending on the order size and location. Our team will provide a detailed timeline once your order is confirmed.

Q: Is there a warranty for the product?

A: Yes, we offer a warranty to ensure customer satisfaction. Please refer to our terms and conditions for full details.

Transform your industrial processes with the Multi-Layer Mesh With Welding Spots from Anping County Ansheng Wire Meshes Product Co., Ltd. Experience superior performance, reliability, and innovation today.

Post time: Jul . 21, 2025 05:20