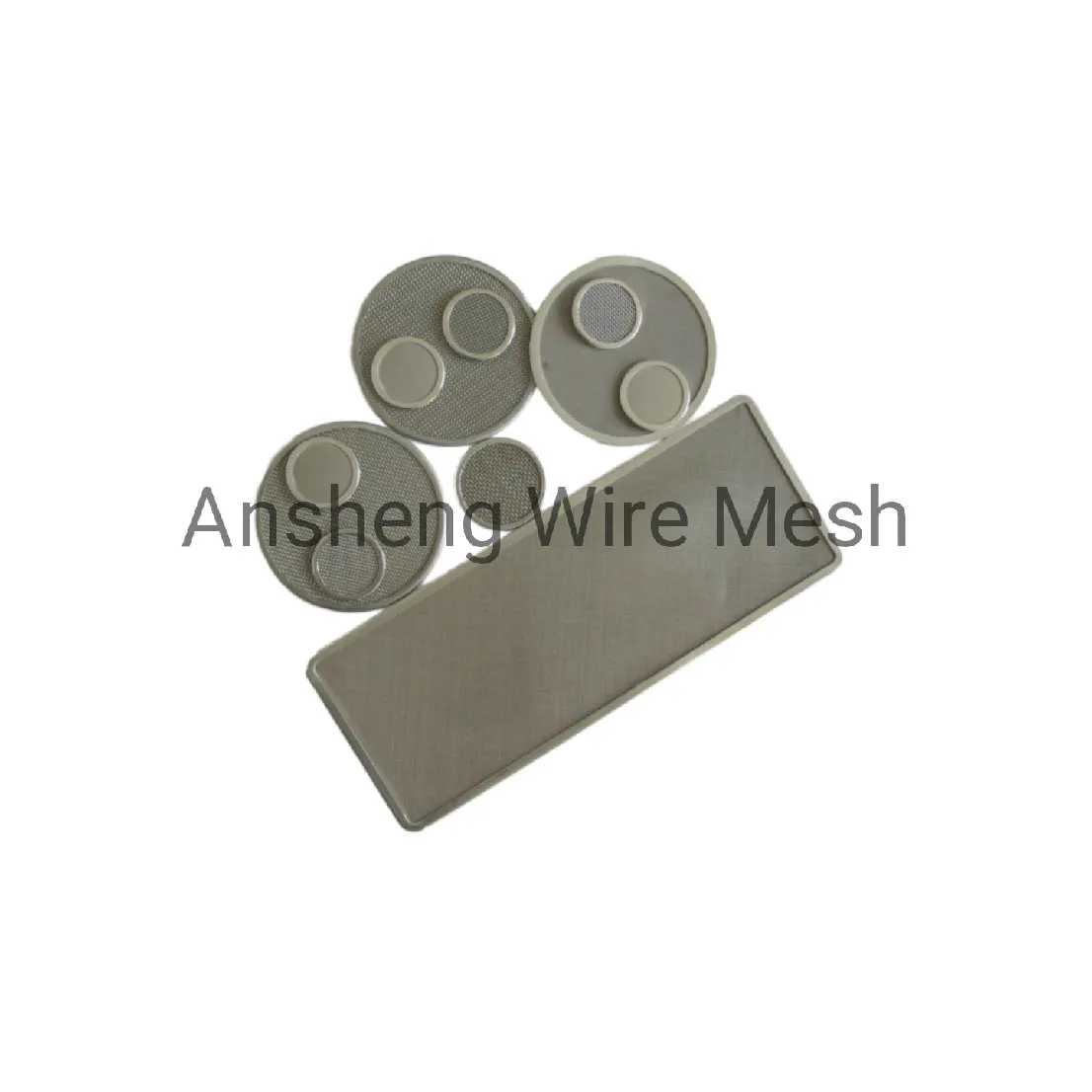

Multi-Layer Mesh With Rim: Enhancing Industrial Filtration Efficiency

As a leading manufacturer in the wire mesh industry, Anping County Ansheng Wire Meshes Product Co., Ltd. presents the Multi-Layer Mesh With Rim, a high-performance solution designed for precision filtration in extrusion and industrial applications. This product combines innovative engineering with durable materials to meet the evolving demands of modern manufacturing.

Product Overview

The Multi-Layer Mesh With Rim is engineered to provide superior filtration efficiency while maintaining structural integrity under demanding conditions. Its multi-layer design ensures optimal particle separation, making it ideal for applications in extruder screens, screen extrusion, and extrusion screens. The rim adds stability, ensuring the mesh remains securely in place during operation.

Key Features & Benefits

- Multi-Layer Construction: Enhances filtration accuracy and extends service life.

- Durable Rim Design: Prevents deformation and ensures long-term reliability.

- Customizable Options: Tailored to fit specific extrusion equipment and operational requirements.

- High-Temperature Resistance: Suitable for high-temperature industrial environments.

Technical Specifications

| Parameter | Details |

|---|---|

| Material | Stainless Steel, Aluminum, or Custom Alloys |

| Mesh Count | 10-300 Mesh (Customizable) |

| Frame Material | Aluminum Extrusion Screen Frame |

| Operating Temperature | -20°C to 600°C (Depending on Material) |

Industry Applications

The Multi-Layer Mesh With Rim is widely used in the following sectors:

- Plastics & Rubber Industry: Ensures consistent material quality during extrusion processes.

- Chemical Processing: Filters corrosive liquids and gases with high precision.

- Food & Beverage: Meets strict hygiene standards for product filtration.

- Automotive Manufacturing: Used in oil and coolant filtration systems.

Why Choose Anping County Ansheng Wire Meshes Product Co., Ltd.?

With over two decades of experience in the wire mesh industry, Anping County Ansheng Wire Meshes Product Co., Ltd. is committed to delivering innovative solutions that address industry-specific challenges. Our advanced manufacturing technology and rigorous quality control processes ensure that every Multi-Layer Mesh With Rim meets international standards.

Customer Testimonials

"The Multi-Layer Mesh With Rim significantly improved our production efficiency. The durability and precision of the product exceeded our expectations." – John Doe, Production Manager at XYZ Industries

"We have been using Anping County Ansheng's products for three years. Their customer support and product quality are unmatched in the market." – Emily Smith, Procurement Director at ABC Manufacturing

Implementation & Customization

Our team provides comprehensive support for product integration, including:

- Technical Consultation: Tailoring mesh specifications to your equipment and process requirements.

- Installation Guidance: Step-by-step instructions for seamless setup.

- After-Sales Support: 24/7 technical assistance and maintenance services.

Environmental & Safety Compliance

The Multi-Layer Mesh With Rim is manufactured using environmentally friendly processes and complies with global safety standards, including fly screen extrusion regulations. It is designed to minimize waste and reduce energy consumption during operation.

Ordering & Logistics

For bulk orders, we offer:

- Custom Packaging: Secure packaging to prevent damage during transit.

- Global Shipping: Reliable logistics partners for timely delivery worldwide.

- Competitive Pricing: Volume discounts for long-term clients.

FAQs

Q: What materials are available for the mesh?

A: We offer stainless steel, aluminum, and custom alloys to suit different industrial requirements.

Q: Can the mesh be customized for specific equipment?

A: Yes, our team provides full customization services to ensure compatibility with your machinery.

Q: What is the typical delivery time?

A: Standard orders are delivered within 7-10 business days, with expedited options available.

Contact Us

Ready to elevate your filtration systems? Contact Anping County Ansheng Wire Meshes Product Co., Ltd. today for a personalized consultation. Visit our product page to explore more details or request a sample.

Conclusion

The Multi-Layer Mesh With Rim from Anping County Ansheng Wire Meshes Product Co., Ltd. offers a reliable, efficient, and customizable solution for industrial filtration needs. With its advanced design and commitment to quality, this product is an essential addition to any manufacturing operation.

Post time: Jul . 21, 2025 05:20