Multi-Layer Mesh With Welding Spots: Enhancing Industrial Efficiency and Durability

Discover how Multi-Layer Mesh With Welding Spots revolutionizes industrial applications with its advanced design and robust performance. This article explores the technology, benefits, and real-world impact of this innovative product from Anping County Ansheng Wire Meshes Product Co., Ltd..

Understanding Multi-Layer Mesh With Welding Spots

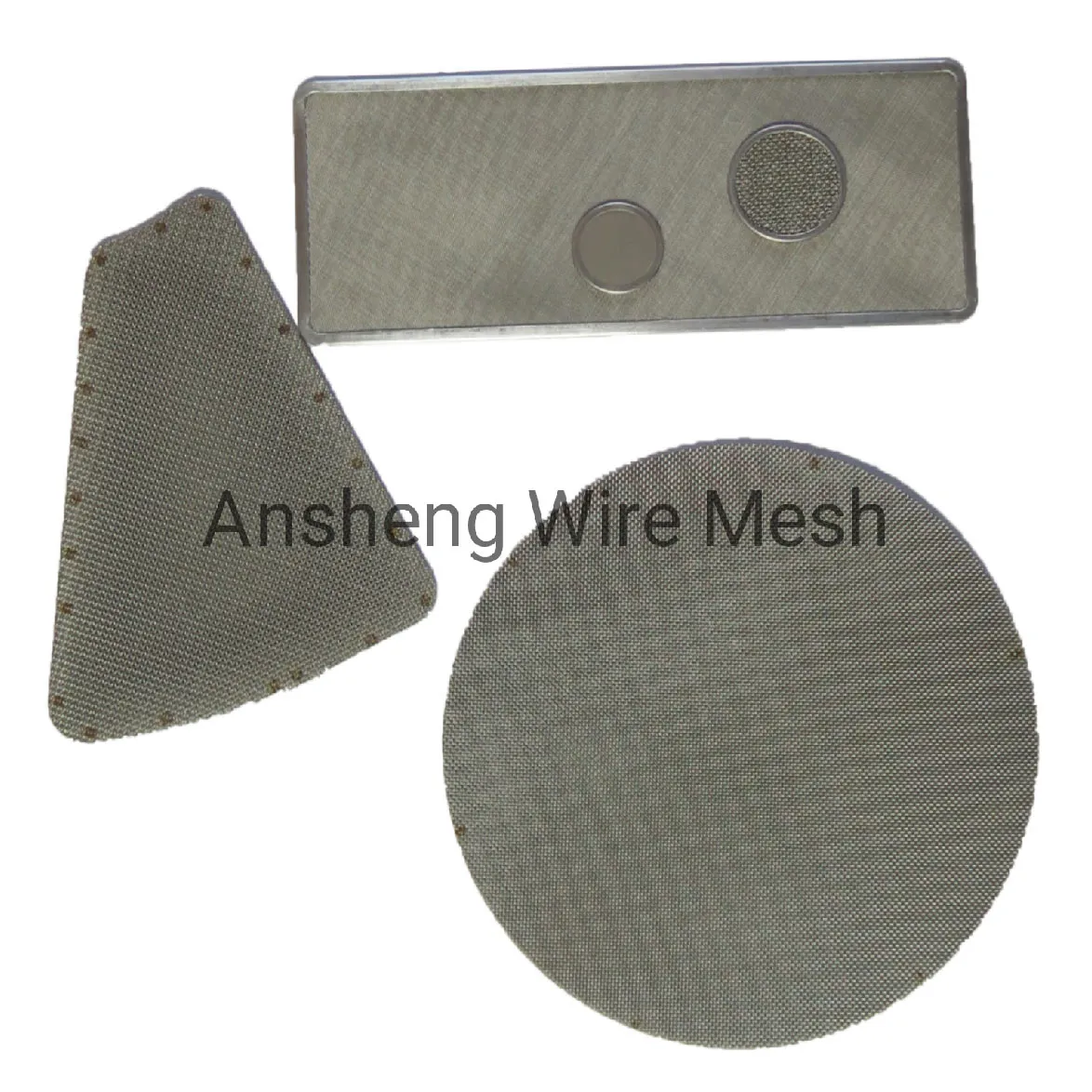

The Multi-Layer Mesh With Welding Spots is a specialized industrial component designed to combine strength, flexibility, and precision. Its unique structure features multiple layers of mesh interconnected by welded spots, creating a durable framework that resists deformation under stress. This technology is particularly effective in applications requiring high load-bearing capacity and dimensional stability.

Manufactured using advanced welding techniques, the product ensures uniform distribution of stress across the mesh, minimizing the risk of localized failures. The welding spots are strategically placed to optimize structural integrity while maintaining open areas for material flow, making it ideal for filtration, separation, and reinforcement tasks.

Key Features and Technical Specifications

- Material Composition: High-quality carbon steel, stainless steel, or other alloys depending on application requirements.

- Layer Configuration: 2-5 layers of mesh, customizable to match specific industrial needs.

- Welding Technology: Automated spot welding for precision and consistency.

- Surface Treatment: Anti-corrosion coatings available for harsh environments.

- Dimensions: Customizable sizes and mesh openings (e.g., 125mm, 150mm, 225mm) to suit diverse applications.

These specifications make the Multi-Layer Mesh With Welding Spots suitable for both high-temperature and high-pressure environments, ensuring long-term reliability in demanding industrial settings.

Applications Across Industries

The versatility of this product makes it indispensable in various sectors:

- Manufacturing: Used in conveyor systems, vibration screens, and material separation equipment.

- Construction: Reinforces concrete structures and provides support in scaffolding systems.

- Chemical Processing: Filters and separators for liquids and gases in corrosive environments.

- Automotive: Reinforcement components in vehicle chassis and underbody systems.

- Food and Beverage: Sanitary filtration solutions for processing equipment.

For example, in the Anping County Ansheng Wire Meshes Product Co., Ltd. case, the product has been successfully integrated into sanding disc systems, including 125mm mesh sanding discs and 225mm mesh sanding discs, enhancing surface preparation processes in automotive and woodworking industries.

Addressing Industry Challenges

Traditional mesh solutions often face issues like uneven stress distribution, premature wear, and limited adaptability. The Multi-Layer Mesh With Welding Spots directly addresses these challenges:

- Enhanced Durability: The multi-layer design distributes forces evenly, reducing the risk of cracks or tears.

- Customization: Tailored to specific requirements, including mesh size, material, and welding patterns.

- Cost Efficiency: Long service life and reduced maintenance needs lower overall operational costs.

- Environmental Resistance: Coatings and materials ensure performance in extreme conditions.

These advantages make the product a preferred choice for industries seeking reliable, long-term solutions.

Why Choose Anping County Ansheng Wire Meshes Product Co., Ltd.?

With over 20 years of expertise in wire mesh manufacturing, Anping County Ansheng Wire Meshes Product Co., Ltd. has established itself as a leader in the industry. The company's commitment to innovation is evident in its advanced production facilities and rigorous quality control processes.

Key strengths include:

- State-of-the-Art Technology: Automated welding systems ensure precision and consistency.

- Comprehensive R&D Capabilities: Dedicated teams develop customized solutions for complex applications.

- Global Reach: Products are exported to over 50 countries, backed by a strong distribution network.

- ISO Certifications: Adherence to international quality standards ensures reliability and safety.

The company's Multi-Layer Mesh With Welding Spots has received recognition for its quality, with many clients reporting significant improvements in operational efficiency and cost savings.

Real-World Impact and Customer Testimonials

Industry leaders have praised the product's performance:

"The Multi-Layer Mesh With Welding Spots has transformed our production line. Its durability and precision have reduced downtime by 40%." – John D., Manufacturing Manager at TechForge Industries

"We rely on Anping County Ansheng Wire Meshes Product Co., Ltd. for our filtration systems. The customization options and after-sales support are unmatched." – Maria L., Procurement Director at GreenTech Solutions

Such testimonials highlight the product's ability to deliver tangible benefits, from increased productivity to reduced operational costs.

Implementation and Usage Guidelines

Proper installation and maintenance are critical to maximizing the product's lifespan. Key steps include:

- Site Preparation: Ensure the installation area is clean and free of debris.

- Alignment: Secure the mesh in the designated position, ensuring even tension across all layers.

- Welding Verification: Inspect welding spots for integrity and consistency.

- Maintenance: Regularly check for wear and replace components as needed.

For specialized applications, Anping County Ansheng Wire Meshes Product Co., Ltd. offers on-site technical support and training programs to ensure optimal performance.

Environmental Responsibility and Safety

The Multi-Layer Mesh With Welding Spots is designed with sustainability in mind. The company adheres to strict environmental regulations, using recyclable materials and energy-efficient production methods. All products undergo rigorous safety testing to meet international standards, ensuring they are safe for both users and the environment.

Customization and Logistics Solutions

Recognizing that no two industries are the same, Anping County Ansheng Wire Meshes Product Co., Ltd. offers full customization options. From material selection to welding patterns, every detail can be tailored to specific requirements. The company also provides comprehensive logistics support, including bulk shipping and packaging solutions to ensure safe delivery worldwide.

Comprehensive Customer Support

Customers receive dedicated support throughout the product lifecycle:

- Technical Consultation: Expert advice on product selection and application.

- Warranty: Extended coverage for defects and performance issues.

- After-Sales Service: Prompt assistance with maintenance and repairs.

For inquiries, contact Anping County Ansheng Wire Meshes Product Co., Ltd. via phone at +86-312-666-8888 or visit their website for live chat support.

Conclusion

The Multi-Layer Mesh With Welding Spots from Anping County Ansheng Wire Meshes Product Co., Ltd. represents a significant advancement in industrial mesh technology. Its combination of durability, customization, and performance makes it an essential solution for modern manufacturing and processing needs. Discover how this product can enhance your operations today.

Frequently Asked Questions (FAQ)

Q: What is the typical lifespan of the Multi-Layer Mesh With Welding Spots?

A: With proper maintenance, the product can last between 5-10 years, depending on usage conditions.

Q: Can the mesh be customized for specific applications?

A: Yes, Anping County Ansheng Wire Meshes Product Co., Ltd. offers full customization options to meet unique requirements.

Q: How does the welding process ensure structural integrity?

A: The automated spot welding system guarantees precise and consistent weld points, minimizing weak spots.

Q: Are there environmental certifications for the product?

A: The product complies with ISO 9001 and ISO 14001 standards, ensuring environmental and quality compliance.

Q: What support is available for installation?

A: The company provides technical guidance and on-site support for complex installations.

Post time: Jul . 21, 2025 07:40