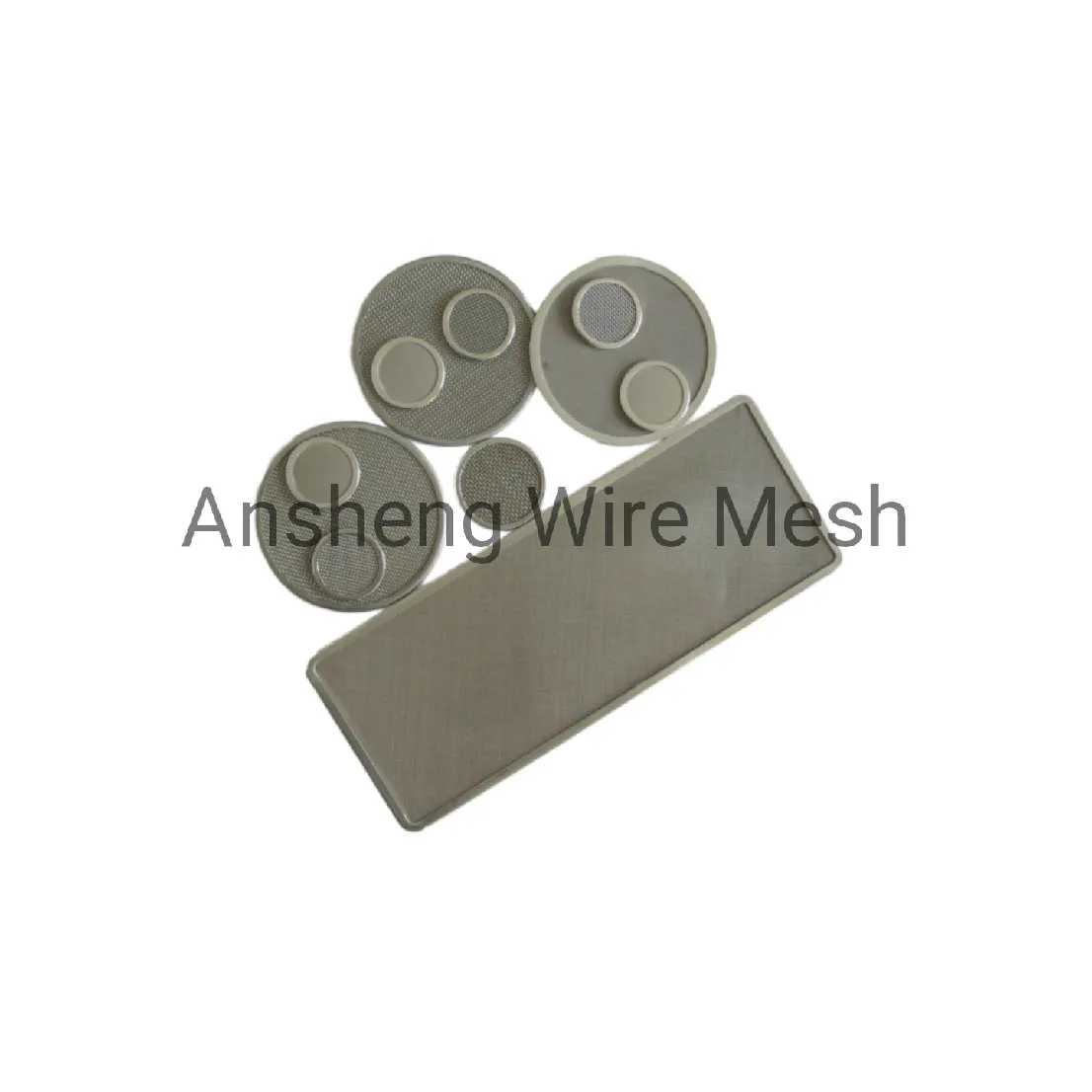

Multi-Layer Mesh With Rim: Enhancing Filtration Efficiency for Industrial Applications

As a leading manufacturer in the filtration industry, Anping County Ansheng Wire Meshes Product Co., Ltd. (安平县安盛丝网制品有限公司) offers the Multi-Layer Mesh With Rim, a high-performance solution designed to meet the demands of industrial filtration systems. This product is engineered with advanced technology to ensure durability, precision, and efficiency in various applications.

Product Overview

The Multi-Layer Mesh With Rim is a specialized filtration component that combines multiple layers of mesh material with a reinforced rim structure. This design ensures optimal filtration efficiency while maintaining structural integrity under high-pressure conditions. The product is widely used in extrusion processes, where precise particle separation and consistent flow control are critical.

Key Features and Advantages

- Multi-Layer Design: The layered mesh structure enhances filtration accuracy, effectively capturing fine particles while allowing smooth fluid flow.

- Reinforced Rim: The durable rim prevents deformation and extends the product's lifespan, even in demanding environments.

- Customizable Options: Available in various mesh sizes and materials (e.g., stainless steel, aluminum) to suit specific industrial requirements.

- High Efficiency: Reduces clogging and maintenance costs, improving overall production efficiency.

Technical Specifications

| Parameter | Details |

|---|---|

| Material | Stainless steel, aluminum, or other custom alloys |

| Mesh Count | 10-300 mesh (customizable) |

| Frame Material | Steel or aluminum with anti-corrosion coating |

| Thickness | 0.5-3mm (depending on application) |

| Operating Temperature | -20°C to 300°C (varies by material) |

Applications in Industrial Processes

The Multi-Layer Mesh With Rim is ideal for a wide range of industries, including:

- Plastics and Polymer Extrusion: Ensures uniform material flow and prevents impurities from entering the final product.

- Chemical Processing: Filters corrosive liquids and gases with high precision.

- Food and Beverage: Maintains hygiene standards by removing contaminants during production.

- Pharmaceuticals: Provides sterile filtration for sensitive drug formulations.

Addressing Industry Challenges

Traditional filtration systems often struggle with clogging, wear, and inefficiency. The Multi-Layer Mesh With Rim tackles these issues through its innovative design:

- Reduced Clogging: The multi-layer structure distributes pressure evenly, minimizing blockages.

- Enhanced Durability: The reinforced rim resists deformation, ensuring long-term performance.

- Cost-Effective: Lower maintenance and replacement frequency reduce operational expenses.

Company Background and Expertise

Anping County Ansheng Wire Meshes Product Co., Ltd. has been a trusted name in the filtration industry for over a decade. With a focus on innovation and quality, the company specializes in producing high-performance extruder screens, screen extrusion, and extrusion screens. Their advanced manufacturing facilities and rigorous quality control processes ensure that every product meets international standards.

Technological Innovation

The company invests heavily in R&D to stay ahead of industry trends. Their team of engineers has developed proprietary technologies that optimize mesh density, frame strength, and corrosion resistance. This commitment to innovation has earned them recognition as a leader in aluminum extrusion screen frame and fly screen extrusion solutions.

Proven Results and Customer Feedback

Customers have reported significant improvements in their production processes after integrating the Multi-Layer Mesh With Rim into their systems. One client in the plastics industry noted, "The product has reduced our downtime by 40% and improved the quality of our extruded materials." Such testimonials highlight the product's effectiveness in real-world applications.

Usage Guidelines and Customization

To maximize the performance of the Multi-Layer Mesh With Rim, follow these steps:

- Choose the appropriate mesh size and material based on your application requirements.

- Ensure proper installation to avoid misalignment or damage.

- Regularly inspect and clean the mesh to maintain efficiency.

For specialized needs, Anping County Ansheng Wire Meshes Product Co., Ltd. offers customized solutions, including tailored mesh configurations and frame designs.

Environmental and Safety Compliance

All products comply with international safety and environmental regulations. The Multi-Layer Mesh With Rim is manufactured using eco-friendly materials and processes, ensuring minimal environmental impact. This commitment to sustainability aligns with global efforts to reduce industrial waste and energy consumption.

Packaging and Delivery

The product is packaged in sturdy, moisture-resistant containers to protect against damage during transit. For bulk orders, customized packaging options are available to meet specific logistics requirements. The company ensures timely delivery through its extensive network of shipping partners.

Customer Support and After-Sales Service

Anping County Ansheng Wire Meshes Product Co., Ltd. provides comprehensive support, including:

- Technical Consultation: Expert advice on product selection and application.

- Training Programs: Workshops to help customers optimize their filtration systems.

- Warranty and Repairs: Extended warranty options and prompt repair services.

For inquiries, contact the company at sales@anshengfilterscreen.com or visit their official website.

Conclusion

The Multi-Layer Mesh With Rim by Anping County Ansheng Wire Meshes Product Co., Ltd. offers a reliable, efficient, and sustainable solution for industrial filtration needs. With its advanced design and commitment to quality, this product is an ideal choice for businesses seeking to enhance productivity and reduce costs.

Frequently Asked Questions (FAQ)

Q1: What materials are used in the Multi-Layer Mesh With Rim?

A: The mesh is available in stainless steel, aluminum, and other custom alloys, while the frame is made of steel or aluminum with anti-corrosion coatings.

Q2: Can the product be customized?

A: Yes, we offer customized mesh sizes, materials, and frame designs to meet specific application requirements.

Q3: How long does the product last?

A: The lifespan depends on usage conditions, but the reinforced rim and high-quality materials ensure long-term durability.

Q4: Is the product environmentally friendly?

A: Yes, all products comply with international environmental standards and are manufactured using sustainable practices.

Q5: What support is available after purchase?

A: We provide technical consultation, training, and warranty services to ensure customer satisfaction.

Post time: Jul . 21, 2025 08:00