Multi-Layer Mesh With Rim: A Practical Guide for Modern Extrusion

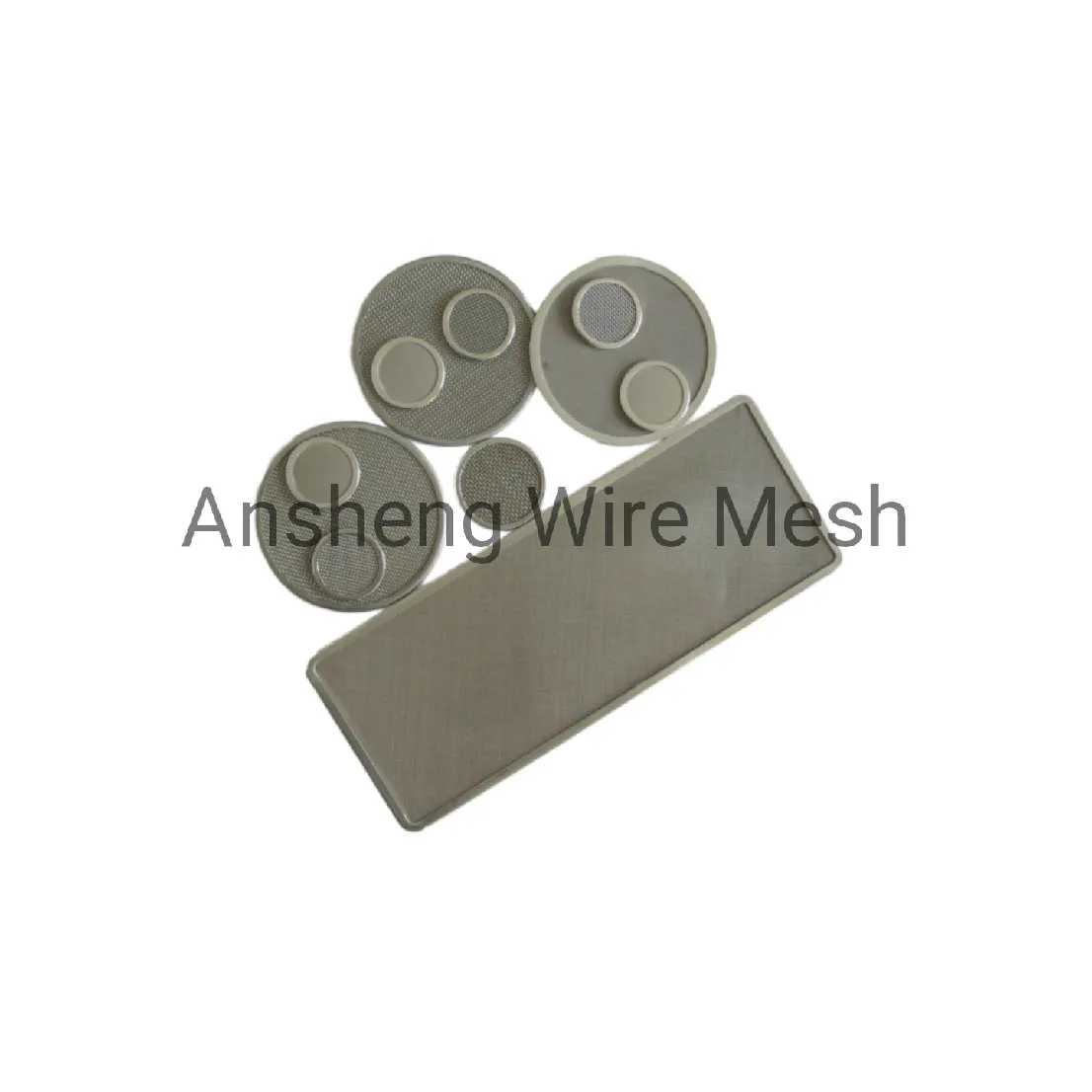

In polymer processing, the humble extruder screens do the quiet heavy lifting—keeping contaminants out, stabilizing melt flow, and frankly, saving operators from hours of cleanup. Ansheng’s Multi-Layer Mesh With Rim (origin: No.346 Xinying East Street, Anping County, Hebei, China) has been making the rounds in extrusion shops I’ve visited—from blown film to recycling—because the rimmed pack is sturdy, easy to swap, and consistent.

What’s Trending (and why it matters)

- Higher recycled content: finer, multi-layer extruder screens to manage gels and wood/fines.

- Tighter tolerances: predictable pressure profiles for high-speed lines.

- Cleaner swaps: rimmed packs cut fraying and time-in-screw by a few precious minutes.

Technical Snapshot

Mesh materials: SS304, 201, 316, 316L, low-carbon steel, galvanized; Rim materials: stainless steel, aluminum. Types: seamed, unseamed. Mesh scope: 1–635; Size: 5–500 mm; Shapes: circle, square, oval, kidney-shaped, rectangle, irregular. Weaves: plain, twill, dutch (for finer retention). Property: secure, smooth edging; uniform aperture. Real-world users tell me 316L holds up best on corrosive recycle blends.

| Parameter | Spec (≈ ranges; real-world use may vary) |

|---|---|

| Mesh count | 1–635 mesh (ASTM E2016 / ISO 9044) |

| Layers | 2–7 layers typical; custom stacks available (e.g., 20/40/80/120) |

| Filtration rating | ≈ 25–500 μm depending on stack/weave |

| Rim thickness | ≈ 0.5–1.0 mm SS or Al (edge-welded, smooth finish) |

| ΔP (clean start) | ≈ 0.1–0.3 MPa at 200–500 kg/h on PE/PP (indicative) |

| Service life | 4–24 h per pack typical; >5 clean cycles (gentle burn-off/ultrasonic) |

Manufacturing & QA Workflow

Materials are sourced to ASTM A580 (stainless wire). Mesh is woven (plain/twill/dutch), stamped or laser-cut, stack-welded, rim-formed, and deburred. Cleaning: solvent or ultrasonic. Tests: aperture conformance per ASTM E2016 / ISO 9044; dimensional tolerance check; burst/backflush test; optional salt-spray for galvanized to ASTM B117. Facilities commonly operate under ISO 9001 systems; certificates of conformity and heat numbers can be provided.

Where They’re Used

- PE/PP blown and cast film, sheet, pipe, and profile extrusion

- Recycling lines (PCR/PIW), masterbatch, compounding

- PVC cable, EVA foam, adhesives, hot-melt, fiber spinning

- Food-contact polymers with SS316L options (compliance documentation on request)

Why Multi-Layer With Rim?

The rim prevents fray, seals better in the breaker plate, and strangely enough, makes operators trust the swap—less mess. Many customers say gel counts drop by ~20–30% when moving from single to multi-layer extruder screens with a graded stack.

| Vendor | Rim & Stack Options | Tolerance | Lead Time | Docs |

|---|---|---|---|---|

| Ansheng (Anping, CN) | Seamed/unseamed; SS/Al rim; 2–7 layers; custom shapes | ≈ ±0.2 mm OD | 7–15 days typical | COC, material certs, test reports |

| Vendor B | Basic rim; limited meshes | ≈ ±0.5 mm | 2–4 weeks | Basic COC |

| Vendor C | Premium; sintered options | ≈ ±0.15 mm | 3–5 weeks | Full dossier; higher cost |

Customization Tips

- Specify mesh stack from coarse-to-fine (20→80→120) to reduce backpressure spikes.

- Choose 316/316L for corrosive or food-adjacent jobs; 304 for general duty.

- Add pull-tabs for fast changeovers; request deburred rims for safe handling.

Field Notes (real plants, real numbers)

Film recycler (LDPE/LLDPE): swapping to 4-layer rimmed extruder screens cut gels by 27% and extended pack life from 4 h to ~6.2 h at 240 kg/h. A medical tubing line reported steadier ΔP (±0.03 MPa) over 8-hour runs—“way fewer diameter alarms,” their process tech told me.

Final Thought

You don’t need magic—just consistent mesh, a smart layer order, and a rim that seals. That’s where these Multi-Layer Mesh With Rim packs slot in nicely.

Authoritative references

- ASTM E2016-20, Standard Specification for Industrial Woven Wire Cloth.

- ISO 9044:2016, Industrial wire screens and woven wire cloth — Technical requirements and testing.

- ASTM A580/A580M-18, Standard Specification for Stainless Steel Wire.

- ISO 9001:2015, Quality management systems — Requirements.

- ASTM B117-19, Standard Practice for Operating Salt Spray (Fog) Apparatus.

Post time: Oct . 16, 2025 12:40