epoxy coated wire mesh for concrete,epoxy coated wire mesh,epoxy coated welded wire mesh,epoxy mesh,epoxy coated mesh is a key solution in the manufacturing industry, specifically within Building materials manufacturing industry and Concrete reinforcement material. This article explores how Anping County Ansheng Wire Meshes Product Co., Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- epoxy coated wire mesh for concrete,epoxy coated wire mesh,epoxy coated welded wire mesh,epoxy mesh,epoxy coated mesh Overview

- Benefits & Use Cases of epoxy coated wire mesh for concrete,epoxy coated wire mesh,epoxy coated welded wire mesh,epoxy mesh,epoxy coated mesh in Concrete reinforcement material

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on epoxy coated wire mesh for concrete,epoxy coated wire mesh,epoxy coated welded wire mesh,epoxy mesh,epoxy coated mesh from Anping County Ansheng Wire Meshes Product Co., Ltd.

epoxy coated wire mesh for concrete,epoxy coated wire mesh,epoxy coated welded wire mesh,epoxy mesh,epoxy coated mesh Overview

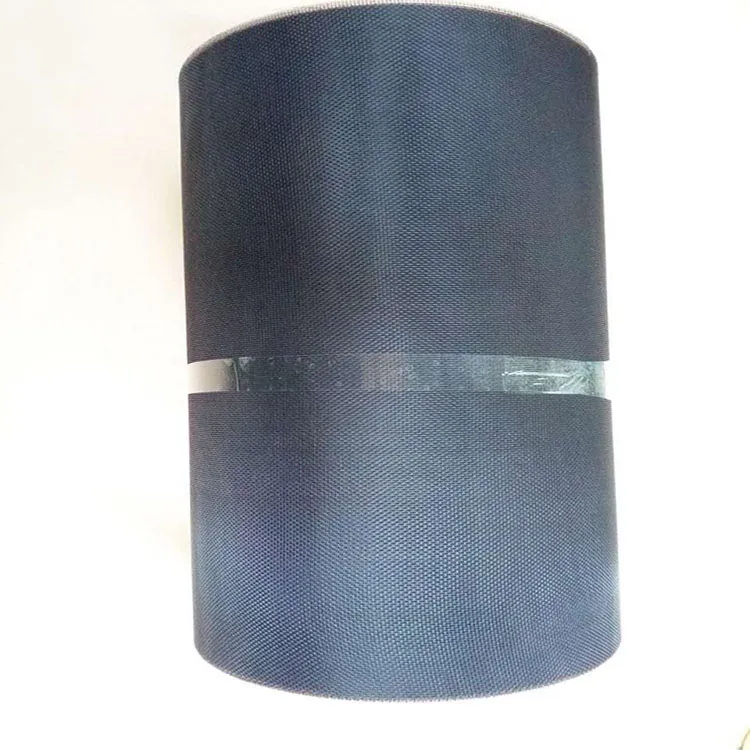

Epoxy coated wire mesh for concrete—often supplied as epoxy coated welded wire mesh—is engineered to enhance corrosion resistance and service life in reinforced concrete. A uniform epoxy layer is applied to low-carbon steel wire mesh through surface preparation, electrostatic powder coating, and curing. The coating helps isolate steel from moisture, chlorides, and chemicals, reducing corrosion initiation and propagation. Typical configurations include mesh openings from small to large formats for slabs, walls, and precast components, with wire diameters tailored to structural requirements. Coatings are commonly specified to industry standards such as ASTM A884/A884M for epoxy coated welded wire reinforcement, aligning the product with demanding infrastructure applications.

Anping County Ansheng Wire Meshes Product Co., Ltd. manufactures epoxy coated mesh with tight quality control—from wire drawing and welding to coating and inspection—ensuring consistent weld integrity, coating adhesion, and dimensional accuracy. Custom options cover sheet or roll supply, cut-to-size fabrication, color coding for traceability, and protective packaging for jobsite handling. For B2B buyers seeking dependable supply and repeatable performance, Ansheng’s epoxy coated wire mesh provides a robust, specification-driven solution.

Benefits & Use Cases of epoxy coated wire mesh for concrete,epoxy coated wire mesh,epoxy coated welded wire mesh,epoxy mesh,epoxy coated mesh in Concrete reinforcement material

In concrete reinforcement, epoxy coated wire mesh delivers durable performance where corrosion risk is elevated—parking structures, coastal and de-icing salt environments, wastewater facilities, industrial floors, tunnels, and precast facade or utility components. The epoxy mesh barrier reduces chloride ingress to the steel, helping retain cross-sectional area and load-carrying capacity over time. With epoxy coated welded wire mesh, sheets lay flat and install quickly, improving labor efficiency compared to loose bars while providing uniform reinforcement distribution for crack control and slab performance.

Key advantages for B2B decision makers include: improved corrosion resistance versus black steel mesh, minimized early-age cracking support via consistent wire spacing, and compatibility with conventional placement and tying methods. Anping County Ansheng Wire Meshes Product Co., Ltd. emphasizes weld strength retention after coating, precise opening sizes, and consistent coating thickness, contributing to predictable bond behavior in concrete and long-term durability. For design-build contractors and precast producers, Ansheng’s epoxy coated wire mesh supports specifications that target longer service life and lower maintenance budgets.

Cost, Maintenance & User Experience

Total cost of ownership matters. While epoxy coated wire mesh typically carries a modest premium over uncoated mesh, the investment is offset by reduced risk of corrosion-related deterioration, fewer repairs, and extended intervals between major rehabilitation cycles. Projects exposed to chlorides or aggressive chemicals often realize measurable life-cycle savings because epoxy coated mesh protects embedded steel during critical early years and beyond.

From a maintenance standpoint, structures reinforced with epoxy coated mesh are designed to need less intervention. On-site, best practices include lifting bundles with soft slings, avoiding coating damage, and using compatible tie wire or plastic-coated ties. B2B customers in the Building materials manufacturing industry report smoother inspections and fewer callbacks when standardized handling protocols are followed. Feedback to Anping County Ansheng Wire Meshes Product Co., Ltd. underscores reliable delivery schedules, consistent coating coverage, and mesh flatness—factors that streamline installation and help maintain project timelines, supporting strong ROI for owners and contractors alike.

Sustainability & Market Trends in manufacturing

Durability is a core pillar of sustainable construction. By extending service life and deferring replacement, epoxy coated wire mesh for concrete reduces material consumption and embodied carbon over a structure’s lifecycle. Powder epoxy coating processes are efficient and can be configured to reduce waste and emissions; combined with precision manufacturing, they align with modern sustainability goals and durability-focused specifications.

Market trends show increasing adoption of corrosion-resistant reinforcement in coastal regions, transportation infrastructure, water/wastewater, and industrial platforms. Specifications referencing durability design, chloride exposure classes, and service-life targets are becoming standard. Anping County Ansheng Wire Meshes Product Co., Ltd. invests in process control and product traceability, positioning its epoxy coated mesh to meet evolving codes and owner requirements. The company collaborates with engineers and contractors to match mesh geometry and coating requirements to project conditions, supporting resilient, cost-effective, and environmentally responsible outcomes.

Conclusion on epoxy coated wire mesh for concrete,epoxy coated wire mesh,epoxy coated welded wire mesh,epoxy mesh,epoxy coated mesh from Anping County Ansheng Wire Meshes Product Co., Ltd.

For concrete structures that must endure aggressive environments, epoxy coated wire mesh—especially epoxy coated welded wire mesh—offers dependable corrosion protection, installation efficiency, and lifecycle value. Backed by manufacturing rigor, Anping County Ansheng Wire Meshes Product Co., Ltd. delivers epoxy mesh solutions that align with stringent specifications and project timelines.

Contact us: email: sales@anshengwiremesh.com

Visit our website: https://www.anshengfilterscreen.com

Post time: Oct . 16, 2025 14:05