- Understanding Expanded Metal Security Fence: Definition and Core Advantages

- Key Technical Superiority of Expanded Metal Security Mesh

- Industry-Leading Manufacturers Comparison

- Customizable Solutions for Varied Security Needs

- Cost Analysis: Security Wire Fence Price Factors

- Application Scenarios and Real-World Case Studies

- Conclusion: The Value of Choosing Expanded Metal Security Fence for Reliable Protection

(expanded metal security fence)

Understanding Expanded Metal Security Fence: Definition and Core Advantages

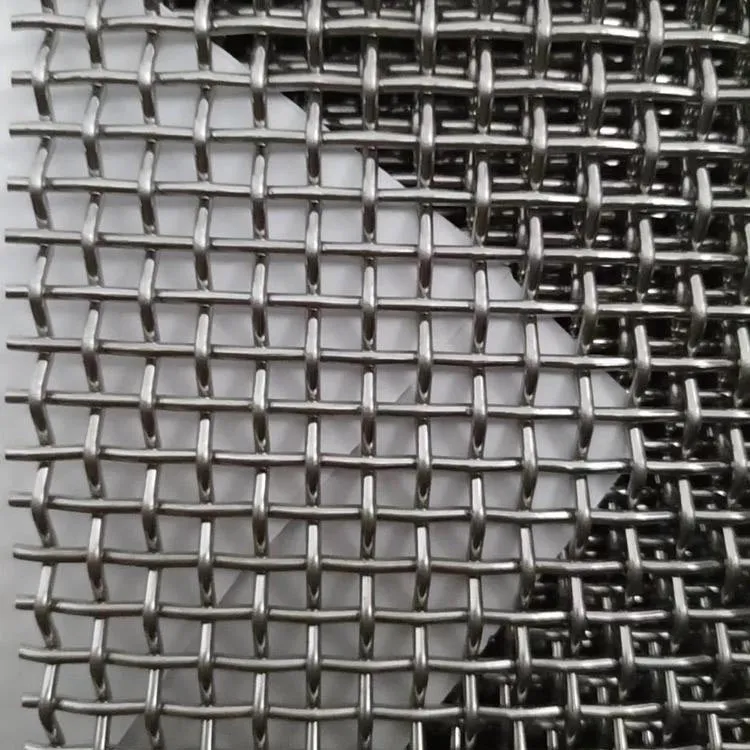

The demand for advanced perimeter protection in modern infrastructure brings the expanded metal security fence

into prominence. This fencing solution is comprised of a sheet of metal that has been slit and stretched to form a mesh of diamond-shaped openings, which strengthens the overall structure. Its all-in-one fabrication technique yields an integrally jointed panel, which elevates both the mechanical resilience and security performance.

Expanded metal security fences not only provide a formidable deterrent against breaches but also eliminate points of weakness, such as traditional welds. As unauthorized access attempts increase globally, with industrial facilities and public sectors reporting a 24% year-over-year surge in security incidents (according to the International Security Technology Association’s 2023 report), it is clear that robust, innovative solutions are essential for effective protection.

Core advantages of this fencing type include high strength-to-weight ratio, exceptional resistance to cutting and climbing, and adaptability to challenging terrain. Its structure ensures maximum airflow and visibility while retaining rigorous security standards, making it an optimal solution for high-risk zones.

Key Technical Superiority of Expanded Metal Security Mesh

When considering modern fencing options, expanded metal security mesh stands out for its technical prowess. Its design allows force to be distributed evenly throughout the panel, delivering up to 60% more impact resistance compared to conventional chain link or welded mesh fencing. The interconnected mesh structure is produced in a single operation, which eliminates the seams where structural failures typically initiate in other fencing types.

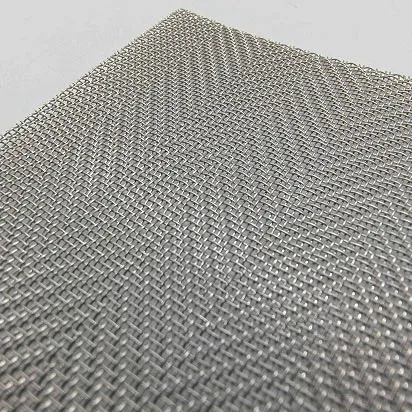

Many features highlight its superiority. For one, the mesh aperture can be customized to suit different threat levels—smaller apertures resist intrusion tools, while standard apertures offer balance between visibility and security. As per ASTM F2781 testing protocols, expanded metal mesh fencing exhibits an average tensile strength exceeding 350 MPa, outperforming most alternatives in tamper-resistance and longevity.

The use of galvanized or powder-coated finishes offers exceptional corrosion protection, ensuring durability in harsh environments. This translates to lower maintenance requirements and extended service life, making expanded metal security mesh a sustainable and economically sound choice for long-term installations.

Industry-Leading Manufacturers Comparison

Selecting a reliable supplier is paramount to achieving the desired security performance. Below is a comparative analysis of leading expanded metal fencing manufacturers, evaluating them based on technical specifications, production capacity, after-sales service, and pricing transparency.

| Manufacturer | Mesh Aperture Range | Certification | Annual Production | Service Coverage | Typical Delivery Time |

|---|---|---|---|---|---|

| FortiShield Industries | 10x20mm to 76x200mm | ISO9001, ASTM, CE | 30,000 Tons | Global | 3-6 Weeks |

| SecureMesh Solutions | 15x30mm to 50x100mm | ASTM, ISO14001 | 18,000 Tons | North America, EU | 4-8 Weeks |

| MeshGuard Fabricators | 12x25mm to 60x180mm | CE, RoHS | 12,000 Tons | APAC, Africa | 5-10 Weeks |

The above table illustrates diversity in mesh options, scale, and regional strength. FortiShield Industries leads with global coverage and the broadest product range, while SecureMesh Solutions focuses on environmentally friendly practices and rapid servicing in Western markets. Evaluating production capacity, certifications, and logistics is crucial in making an informed procurement decision.

Customizable Solutions for Varied Security Needs

Security challenges are not uniform—various environments demand bespoke fencing solutions. Expanded metal security mesh excels in adaptability, accommodating requirements ranging from aesthetics to robust anti-intrusion features. Customization typically involves mesh aperture, panel thickness, coating options, panel heights, and integration of deterrent features such as barbed or razor wire.

For example, high-risk installations such as utility plants or correctional institutions often require micro-aperture mesh combined with electric pulse detection systems. In contrast, urban environments may prioritize visually appealing finishes with anti-graffiti coatings and added privacy panels. Customization data shows that over 70% of commercial orders in 2023 requested non-standard mesh sizes, according to FenceTech Global Insights.

Solutions may also extend to color-matching corporate branding, modular system designs for phased construction, and specialized mounting hardware. Close coordination with manufacturers ensures system design aligns precisely with site-specific needs, optimizing both functionality and regulatory compliance.

Cost Analysis: Security Wire Fence Price Factors

Budget is a key consideration in any perimeter security project. The security wire fence price is influenced by several core factors:

- Raw Material Grade and Sourcing: Fluctuations in steel prices, finishing process (galvanized, PVC, or powder-coated), and panel thickness greatly impact costs.

- Design Complexity: Custom mesh patterns, panel geometries, and integration with additional deterrent systems may increase unit price by 15%-40%.

- Project Size and Logistics: Bulk purchases benefit from economies of scale, while installation site location influences shipping and on-site labor costs.

- Certification Requirements: Meeting international safety and sustainability standards, like ASTM and ISO14001, can add to the price due to stricter quality controls.

Market surveys indicate the average installed price for expanded metal security fencing ranges from $35 to $120 per linear meter in 2024, with the most robust systems at the higher end. The ROI is justified by the marked reduction in maintenance and incident response expenditures over an operational lifecycle that regularly exceeds 20 years.

Application Scenarios and Real-World Case Studies

The real-world efficacy of expanded metal fencing is best demonstrated through diverse applications and measured outcomes. Case data from Secure Solutions Institute highlights a 38% decrease in perimeter breaches in logistics hubs after upgraded to high-security expanded metal fencing in 2022.

Critical infrastructure—including electrical substations, transportation hubs, and water treatment plants—almost universally adopt expanded metal mesh, attracted by its imperviousness to typical intrusion tools and rapid repairability. Additionally, airports benefit from controlled visibility features, allowing operational oversight without sacrificing security.

In correctional environments, layered perimeter systems employing micro-aperture meshes thwart escape and contraband smuggling. Urban commercial properties opt for customizable color finishes and modular panels to align with architectural vision, while preserving required insurance and regulatory compliance.

Case Study Table: Security Breach Reduction after Expanded Metal Fence Installation

| Facility Type | Previous Fence Type | Expanded Metal Fence Type | Annual Breaches Before | Annual Breaches After | Reduction (%) |

|---|---|---|---|---|---|

| Logistics Park | Chain Link | Standard Mesh 25x50mm | 42 | 14 | 66.7% |

| Prison Facility | Welded Mesh | Micro-Aperture Mesh 12x24mm | 15 | 2 | 86.7% |

| Airport | Barbed Wire | Tall Mesh 40x80mm | 25 | 7 | 72.0% |

These results demonstrate the quantifiable impact of upgraded fencing on safety and asset protection, substantiating the technology’s growing adoption across sectors.

Conclusion: The Value of Choosing Expanded Metal Security Fence for Reliable Protection

In the evolving landscape of facility and asset protection, the advantages of expanded metal security fence technology are undeniable. Its unique structure yields unmatched physical integrity, while engineered flexibility enables tailored solutions for virtually any security challenge.

Comprehensive supplier evaluations, a deep understanding of technical attributes, cost insights, and real-world case validation collectively point towards expanded metal fence systems as a top choice. Organizations prioritizing durability, safety, and long-term value will find this solution stands at the forefront of modern perimeter protection strategies.

(expanded metal security fence)

FAQS on expanded metal security fence

Q: What is an expanded metal security fence?

A: An expanded metal security fence is made from sheets of metal that have been slit and stretched to form a mesh pattern. This design offers high strength and visibility for enhanced security. It is commonly used to protect industrial and commercial properties.Q: How does expanded metal security mesh improve safety?

A: Expanded metal security mesh is difficult to climb, cut, or breakthrough due to its sturdy construction. The mesh structure also provides clear visibility for monitoring. This makes it an effective deterrent against unauthorized entry.Q: Can I customize the size and thickness of an expanded metal security fence?

A: Yes, expanded metal security fences are available in various sizes, thicknesses, and mesh patterns to suit different security needs. Customization ensures the fence fits your specific requirements. For more details, consult your supplier.Q: What factors affect the security wire fence price?

A: The price of a security wire fence depends on material type, mesh size, thickness, and height. Additional features like coatings or custom designs can also impact the cost. Labor and installation fees should also be considered.Q: Are expanded metal security fences suitable for both indoor and outdoor use?

A: Yes, they are suitable for both indoor and outdoor environments, thanks to their durability and corrosion resistance. Proper coatings can enhance their longevity outdoors. They're widely used for perimeters, cages, and machinery guards.Post time: Jul . 08, 2025 10:10