The Indispensable Role of Expanded Metal in Modern Industry

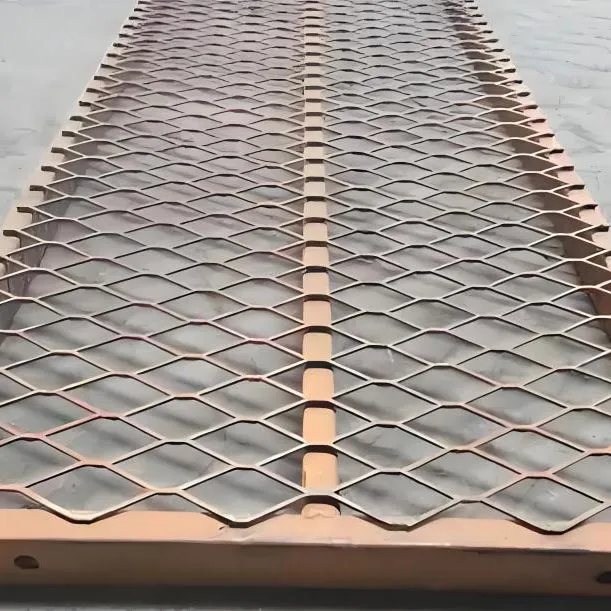

Expanded metal represents a highly versatile and cost-effective material, engineered from a single sheet of metal that is uniformly slit and stretched, forming a diamond-shaped pattern of openings. This unique manufacturing process creates a mesh product that is stronger per pound than the original sheet metal, allowing for optimal structural integrity alongside excellent airflow and light penetration. Its inherent strength-to-weight ratio, coupled with its anti-skid properties and diverse material compatibility, makes it an essential component across a multitude of industrial and architectural applications. Businesses seeking high-performance, durable, and adaptable material solutions for filtration, security, construction, and aesthetic design often find the ideal answer in this product category.

When sourcing high-quality solutions, discerning buyers often search for expanded metal for sale that meets stringent technical specifications and performance requirements. The global market offers a wide array of options, varying in material, mesh size, thickness, and finish, catering to the specific demands of complex engineering projects. From heavy-duty industrial platforms to intricate architectural facades, the application potential of expanded metal is virtually limitless, driven by its unique blend of attributes.

Precision Manufacturing: The Expanded Metal Production Process

The manufacturing of expanded metal is a precise mechanical process, transforming solid metal sheets into a mesh without any material loss. This contrasts sharply with weaving or welding, making it an exceptionally efficient and environmentally conscious method. The core steps involved ensure the material retains its strength while gaining new structural properties:

Process Flow:

- Material Selection: High-quality coils or sheets of various metals are selected. Common materials include carbon steel, galvanized steel, stainless steel (304, 316, 316L), aluminum, copper, and nickel. The choice depends on the application's demands for corrosion resistance, strength, weight, and conductivity.

- Shearing/Slitting: The selected metal sheet is fed into an expanding machine, where a series of dies precisely slit the material. This is not a cutting process that removes material but rather a controlled incision.

- Expanding/Stretching: Immediately after slitting, the machine simultaneously stretches the sheet, causing the slits to open into uniform diamond-shaped apertures. This stretching action actually increases the material's structural rigidity and distributes load efficiently. The "knuckles" – the unslit portions where strands intersect – are crucial for the product's strength.

- Flattening (Optional): For specific applications requiring a smoother surface, the standard (raised) expanded metal can be cold-rolled. This flattening process reduces the thickness and creates a flat, smooth surface while retaining the original mesh pattern. This is often referred to as flattened expanded mesh.

- Finishing: Depending on client specifications and environmental exposure, the expanded metal may undergo further treatments such as galvanization (hot-dip or electro-galvanizing), PVC coating, powder coating, or anodizing (for aluminum). These finishes enhance corrosion resistance, aesthetics, and overall service life.

- Quality Control and Testing: Each batch of expanded metal undergoes rigorous quality checks to ensure compliance with industry standards such as ASTM F1267 for metal expanded metal (general purpose), ISO 9001 for quality management systems, and often specific client-mandated performance tests. These tests include dimensional accuracy (SWD, LWD, strand width, thickness), material composition verification, tensile strength, and corrosion resistance assessments. The service life of properly specified and maintained expanded metal can exceed 20 years, even in harsh industrial environments.

This meticulous manufacturing process ensures that the finished product, whether it's standard or flattened expanded steel mesh, delivers optimal performance in target industries such as petrochemical (for platforms and gratings offering energy saving and corrosion resistance), metallurgy (furnace screens, high-temperature applications), and water supply & drainage (filtration screens, anti-debris barriers).

Industry Trends and Market Dynamics for Expanded Metal Solutions

The market for expanded metal for sale is experiencing robust growth, driven by several key global trends. Increasing infrastructure development, particularly in emerging economies, fuels demand for materials suitable for construction, architectural cladding, and safety applications. The rising emphasis on security and access control has also bolstered the use of expanded metal in fencing, barriers, and window guards, offering both visibility and robust protection.

Technological advancements are leading to more precise manufacturing techniques, allowing for a wider range of patterns, materials, and finishes. This expanded versatility is opening up new markets in aesthetic design and specialized filtration systems. Furthermore, the push for sustainable and resource-efficient materials favors expanded metal due to its no-waste production process and its ability to reduce material consumption while maintaining strength. The global expanded metal market size was valued at USD 2.1 billion in 2022 and is projected to reach USD 3.0 billion by 2030, growing at a CAGR of 4.5% (Source: Grand View Research, 2023). This growth is primarily attributed to its widespread adoption across construction, automotive, and industrial sectors.

Technical Specifications and Product Parameters

Understanding the technical parameters of expanded metal is crucial for proper material selection. The unique geometry is defined by several key measurements:

- SWD (Short Way of Diamond): The distance from a point on a knuckle to a corresponding point on the adjacent knuckle, measured across the short dimension of the diamond.

- LWD (Long Way of Diamond): The distance from a point on a knuckle to a corresponding point on the adjacent knuckle, measured across the long dimension of the diamond.

- Strand Width: The width of the individual metal strips that form the diamond pattern.

- Gauge/Thickness: The thickness of the original metal sheet from which the expanded metal is produced.

- Overall Thickness: For standard (raised) expanded metal, this is the measurement from the top plane to the bottom plane of the expanded sheet.

- Open Area Percentage: The ratio of the area of the openings to the total area of the sheet, crucial for airflow, light transmission, and filtration efficiency.

Below is a table outlining typical specifications for common forms of expanded metal, often sought after as expanded mesh or expanded steel mesh, including a popular size like 4x8 expanded metal sheets.

| Type | Material | Mesh Size (LWD x SWD) | Gauge (Thickness) | Strand Width | Typical Sheet Size |

|---|---|---|---|---|---|

| Standard Expanded Metal | Carbon Steel, Stainless Steel | 1.0" x 0.5" (25x12mm) | 12GA (2.66mm) | 0.125" (3.175mm) | 4' x 8' (1.22m x 2.44m) |

| Flattened Expanded Metal | Aluminum, Galvanized Steel | 0.75" x 0.375" (19x9.5mm) | 16GA (1.61mm) | 0.075" (1.9mm) | 4' x 10' (1.22m x 3.05m) |

| Heavy Duty Expanded Metal | Heavy Gauge Carbon Steel | 2.0" x 0.75" (50x19mm) | 6GA (4.11mm) | 0.250" (6.35mm) | 6' x 12' (1.83m x 3.66m) |

Diverse Application Scenarios of Expanded Metal

The inherent properties of expanded metal make it exceptionally suitable for a vast array of applications across numerous industries. Its versatility stems from its combination of strength, open area, light weight, and aesthetic appeal.

- Industrial Platforms & Walkways: Used extensively in oil & gas, chemical processing, and manufacturing plants, offering anti-skid surfaces, excellent drainage, and high load-bearing capacity for safety and operational efficiency.

- Security Fencing & Barriers: Its rigid, unjoined structure makes it difficult to cut or climb, providing superior security for properties, infrastructure, and public spaces.

- Architectural Facades & Cladding: Increasingly utilized for modern building designs, providing aesthetic appeal, solar shading, ventilation, and a degree of privacy, often customized for unique patterns.

- Filtration & Screens: Applied in HVAC systems, automotive filters, and wastewater treatment, where precise pore sizes are required for effective separation of solids from liquids or gases.

- Grating & Stair Treads: Provides durable, slip-resistant surfaces for industrial grates, stairways, and mezzanines.

- Reinforcement: Acts as an effective reinforcement mesh in concrete or plaster, enhancing structural integrity and preventing cracking.

- Animal Enclosures & Cages: Offers robust yet breathable enclosures for livestock, poultry, and pets, allowing for good ventilation and visibility.

Technical Advantages of Utilizing Expanded Metal

The unique characteristics derived from its manufacturing process bestow a range of significant technical advantages upon expanded metal, making it a preferred choice for engineers and specifiers:

- Superior Strength-to-Weight Ratio: Unlike woven or welded mesh, expanded metal is a single, integral piece of metal, meaning there are no welds or interlocks that can fail. This structural integrity makes it remarkably strong and rigid for its weight, enabling designs that are both robust and efficient in material usage.

- Excellent Air, Light, and Liquid Flow: The open mesh design allows for unrestricted passage of air, light, heat, and liquids, crucial for ventilation systems, solar shading, and drainage applications. This also contributes to energy efficiency in buildings by promoting natural ventilation and daylighting.

- Cost-Effectiveness & Sustainability: The manufacturing process generates no scrap, optimizing material usage and reducing waste, which translates to lower production costs and a smaller environmental footprint. For industries seeking a sustainable and economical expanded metal for sale, this is a significant benefit.

- Anti-Skid Properties: The raised knuckles of standard expanded metal provide a naturally textured, slip-resistant surface, making it ideal for safety gratings, ramps, and stair treads in industrial environments, significantly reducing workplace hazards.

- Durability & Corrosion Resistance: When produced from materials like stainless steel or galvanized steel, or post-processed with coatings, expanded metal offers exceptional resistance to corrosion, abrasion, and extreme temperatures, ensuring a long service life even in harsh conditions.

- Enhanced Security: The absence of welds and the difficulty in cutting the interconnected strands make expanded metal a superior choice for security applications, deterring intruders more effectively than conventional fencing or screening materials.

Vendor Comparison: Selecting the Right Expanded Metal Supplier

Choosing the right supplier for expanded metal for sale is paramount for project success, impacting quality, cost, and lead times. A strategic vendor comparison should consider several critical factors:

| Criterion | Importance | Considerations & Questions for Vendors |

|---|---|---|

| Material Quality & Sourcing | High | Are materials certified (e.g., mill certificates)? What are the common alloys and finishes offered? Can they provide samples? |

| Technical Expertise & Customization | High | Do they offer design support for custom mesh patterns or sizes (e.g., 4x8 expanded metal with specific openings)? Can they produce non-standard forms of expanded mesh? |

| Certifications & Standards Compliance | Very High | Are they ISO 9001 certified? Do products meet ASTM, ANSI, or local standards? Can they provide test data? |

| Lead Time & Production Capacity | High | What are typical lead times for standard and custom orders? Do they have sufficient capacity for large-volume orders of expanded steel mesh? |

| Pricing & Payment Terms | Medium-High | Request detailed quotes, understand pricing structures for volume, and inquire about payment terms and credit options. |

| Customer Support & After-Sales Service | High | What level of technical support is available? What are their warranty policies and handling procedures for non-conformances? |

An experienced vendor will provide comprehensive technical data, case studies, and responsive communication, demonstrating a deep understanding of product applications and customer needs. Look for suppliers with a proven track record and positive client testimonials, reflecting their reliability and commitment to quality.

Customized Solutions and Fabrication Services

While standard sizes and patterns of expanded metal are widely available, many B2B applications demand bespoke solutions. Leading manufacturers offer comprehensive customization services, allowing clients to specify nearly every aspect of the expanded metal product to perfectly match their project requirements. This includes:

- Tailored Mesh Sizes and Patterns: Custom SWD and LWD dimensions, strand widths, and gauges can be produced to achieve specific open area percentages, structural strength, or aesthetic effects.

- Special Materials and Alloys: Beyond common steel and aluminum, specialized materials like titanium, copper, or exotic alloys can be expanded for niche applications requiring unique properties (e.g., high-temperature resistance, specific conductivity).

- Precision Cutting and Forming: Suppliers can cut expanded metal to exact dimensions (e.g., specific 4x8 expanded metal sheets or smaller components), bend, roll, or weld it into complex shapes, or frame it for easy installation.

- Specialized Finishes: Custom coating solutions, including specific colors for powder coating, anodizing, or specialized anti-corrosion treatments, can be applied to meet environmental, aesthetic, or performance criteria.

Engaging with a manufacturer capable of delivering customized expanded metal solutions ensures optimal fit, superior performance, and often, significant cost savings by minimizing on-site modifications and waste.

Application Case Studies: Expanded Metal in Action

Case Study 1: Petrochemical Facility Safety Platforms

A major petrochemical complex required highly durable, anti-skid, and corrosion-resistant platforms and walkways for their distillation towers and pipe racks. Traditional grating was considered, but the risk of tools falling through and the need for optimal drainage in spill-prone areas led them to specify heavy-gauge stainless steel expanded metal. The selected expanded metal for sale provided superior surface grip even when wet or oily, enhanced ventilation reducing heat build-up, and its integral construction eliminated potential weld failures. The outcome was a significant improvement in worker safety and a reduction in maintenance due to the material's inherent resistance to corrosive agents prevalent in the facility.

Case Study 2: Urban Architectural Facade

A contemporary office building in a bustling city sought an aesthetic yet functional facade material to reduce solar gain, allow natural light, and create a distinctive architectural statement. Custom-designed flattened aluminum expanded mesh panels, powder-coated in a specific metallic finish, were chosen. The varying LWD and SWD of the mesh created a dynamic visual texture that changed with light conditions. The open area allowed for sufficient natural light penetration while effectively dissipating solar heat, contributing to the building's energy efficiency. This project showcased the material's potential as both a performance component and an artistic element in modern architecture.

Case Study 3: Data Center Security Cages

A leading data center required highly secure yet breathable enclosures for server racks and critical infrastructure within its facility. Standard wire mesh fencing was deemed insufficient due to potential for cutting and climbing. Hot-dip galvanized expanded steel mesh panels were custom-fabricated into modular security cages. The unyielding structure of the expanded metal provided robust protection against unauthorized access, while its open design allowed for optimal airflow, crucial for preventing server overheating. The galvanized finish ensured long-term durability and resistance to environmental factors, providing a reliable and visually integrated security solution.

Ensuring Trust and Authority: Certifications, Support & FAQs

Authoritativeness & Certifications

Our commitment to quality and industry standards is unwavering. Products offered for expanded metal for sale are manufactured under strict quality control, adhering to ISO 9001:2015 certified processes. Our facilities are regularly audited to ensure consistent product excellence and operational efficiency. Materials are sourced from reputable suppliers and accompanied by verifiable mill test certificates. We have served global industries for over 15 years, building strong partnerships with leading engineering firms and contractors who rely on our consistent quality and technical support. Our test data, available upon request, validates product performance against recognized ASTM and ANSI standards.

Trustworthiness: Lead Time, Warranty & Support

- Lead Time & Fulfillment: Standard products like common 4x8 expanded metal sheets typically have a lead time of 7-14 business days, depending on volume. Customized orders require 3-5 weeks from drawing approval. We maintain robust logistics to ensure timely and secure delivery worldwide.

- Warranty Commitments: All our expanded metal products come with a comprehensive 5-year warranty against manufacturing defects and material failures under normal operating conditions. Extended warranties are available for specific project requirements.

- Customer Support: Our dedicated technical support team is available from 8 AM to 6 PM (GMT+8) via phone and email to assist with product selection, technical queries, installation guidance, and after-sales service. We pride ourselves on responsive and knowledgeable support.

Frequently Asked Questions (FAQs)

- Q1: What is the difference between standard and flattened expanded metal?

- A1: Standard (raised) expanded metal has ridges from the expansion process, providing anti-skid properties. Flattened expanded metal is cold-rolled after expansion, creating a smooth, flat surface that is easier to handle and cut, with reduced overall thickness.

- Q2: Can expanded metal be used outdoors?

- A2: Absolutely. When manufactured from appropriate materials like galvanized steel, stainless steel, or aluminum, and/or coated with durable finishes (e.g., powder coating), expanded metal offers excellent corrosion resistance and longevity in outdoor environments.

- Q3: How do I specify the correct expanded metal for my project?

- A3: Key specifications include material type, mesh size (LWD x SWD), gauge/thickness, strand width, type (standard or flattened), and any required finishes. Our technical team can assist you in selecting the optimal product based on your application's load requirements, environmental conditions, and aesthetic needs.

- Q4: Is expanded metal recyclable?

- A4: Yes, as it's typically made from single-sheet metals, expanded metal is fully recyclable, contributing to sustainable construction and manufacturing practices.

Conclusion

Expanded metal stands as a testament to innovative material engineering, offering an unparalleled blend of strength, versatility, and cost-efficiency. Its unique manufacturing process, which transforms a solid sheet into a robust mesh without material loss, positions it as an environmentally friendly and economically smart choice for a broad spectrum of industrial, architectural, and security applications. From critical safety platforms in petrochemical plants to visually striking building facades, the adaptability of expanded metal continues to drive its increasing adoption across various sectors.

For B2B decision-makers and engineers, understanding the technical specifications, application advantages, and the importance of partnering with an authoritative and trustworthy vendor are key to unlocking the full potential of this exceptional material. As industries evolve and demand more efficient, durable, and sustainable solutions, the value proposition of high-quality expanded metal for sale will only continue to grow.

References

- ASTM International. (2020). ASTM F1267-07(2020) Standard Specification for Metal Expanded Metal Products.

- Grand View Research. (2023). Expanded Metal Market Size, Share & Trends Analysis Report.

- International Organization for Standardization. (2015). ISO 9001:2015 Quality management systems — Requirements.

- Metal Architecture Magazine. (2022). The Versatility of Expanded Metal in Modern Building Design.

Post time: Sep . 24, 2025 09:10