Unraveling Innovation: Top Wire Mesh Manufacturers at Wire & Tube Düsseldorf

Wire & Tube Düsseldorf, the world's premier trade fair for the wire, cable, and tube industries, is far more than just an exhibition; it's a vibrant nexus of innovation, a strategic meeting point where the future of industrial applications takes shape. For B2B decision-makers in the manufacturing, construction, automotive, and filtration sectors, this event serves as an unparalleled platform to witness groundbreaking advancements in wire mesh and advanced filtration solutions. It's where the latest technologies, materials, and production techniques are unveiled, offering invaluable insights and partnership opportunities that drive progress across the globe. Attendees gain first-hand access to cutting-edge products, forge crucial business connections, and stay abreast of the dynamic shifts influencing global industrial landscapes.

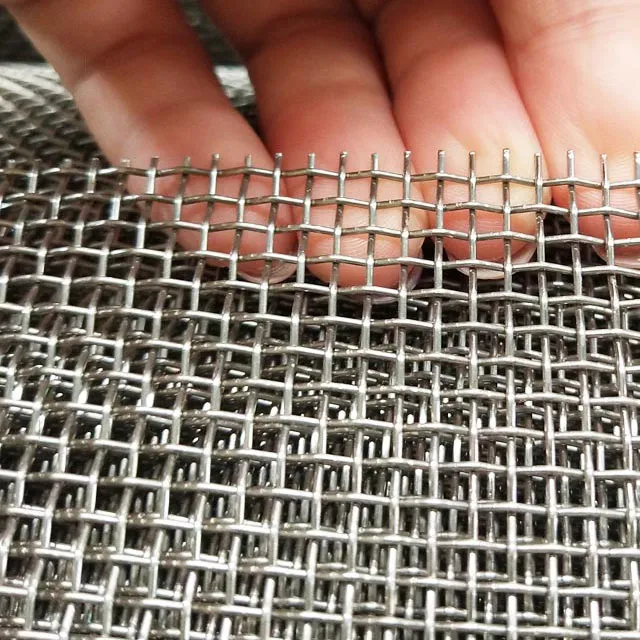

The importance of wire mesh in modern industry cannot be overstated. From critical filtration systems and robust structural components to sophisticated shielding and precise separation processes, its applications are as diverse as they are essential. Whether it's the precise weaving of a plain weave mesh for medical devices or the robust structure of a plain steel mesh for architectural applications, quality and reliability are paramount. Wire & Tube Düsseldorf provides a unique lens through which to observe the evolving landscape of this crucial industry, spotlighting manufacturers who are pushing the boundaries of what's possible and setting new benchmarks for quality and performance, particularly from leading Chinese innovators.

Industry Trend Spotlight: Precision, Performance, and Sustainability Driving Wire Mesh Evolution

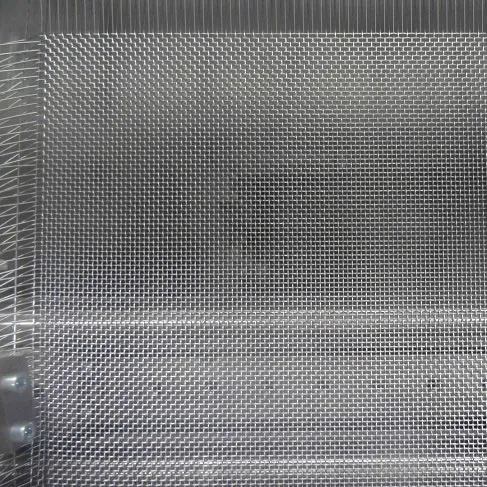

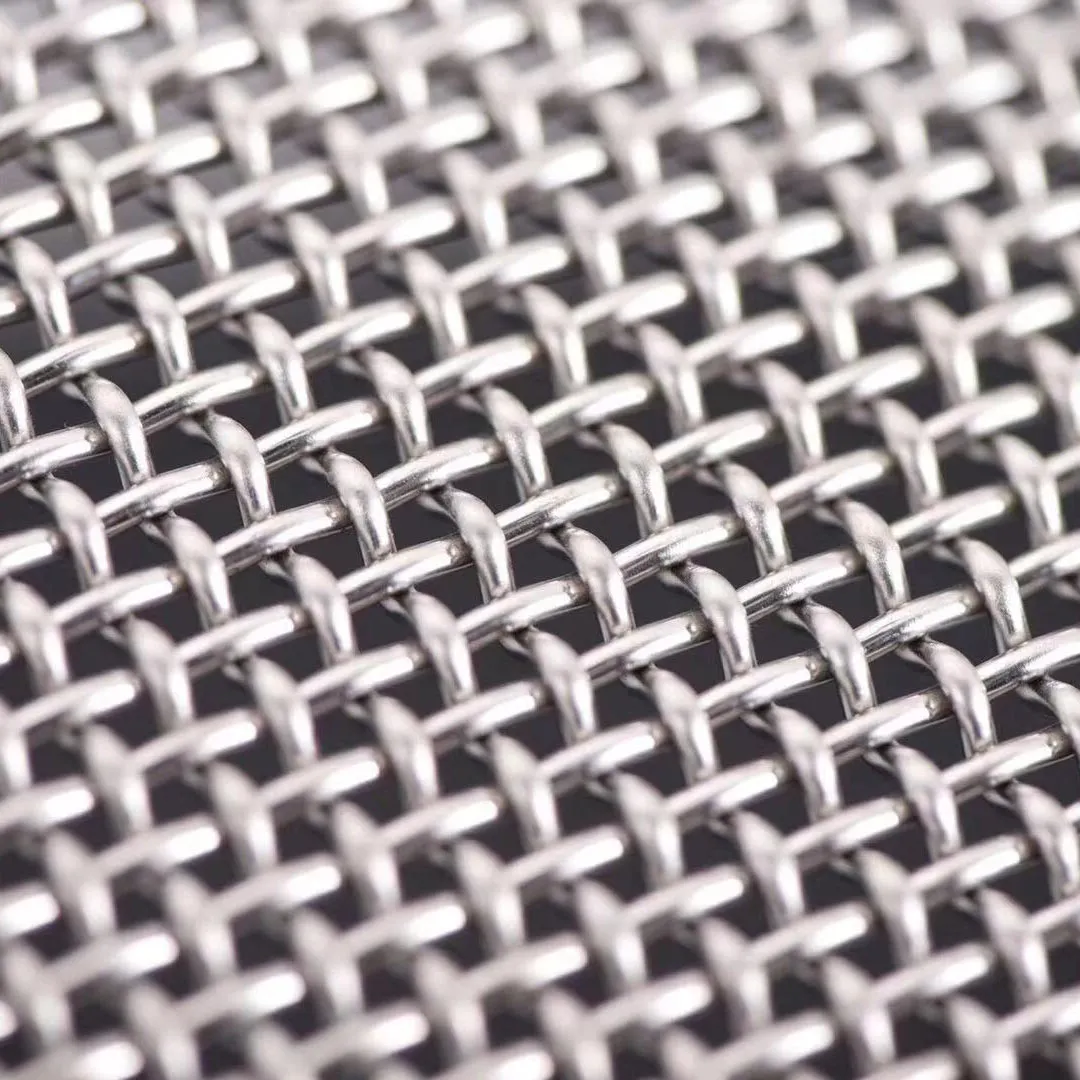

The wire mesh industry is currently undergoing a transformative phase, driven by a confluence of technological advancements, environmental imperatives, and escalating industrial demands. Globally, there's a significant surge in demand for high-precision woven wire mesh, particularly for applications requiring extremely fine filtration and separation in sensitive environments. This includes the widespread adoption of specific types like plain weave mesh and plain mesh, which are highly valued for their consistent aperture size, superior filtration efficiency, and robust structure. These characteristics make them indispensable in critical sectors such as chemical processing, pharmaceuticals, food and beverage, and advanced water treatment systems, where particle retention and flow characteristics are meticulously controlled.

Beyond traditional materials, enhanced corrosion-resistant materials are gaining significant global attention. Specialists are increasingly turning to advanced alloys such as Duplex stainless steel and various nickel alloys (e.g., Inconel, Monel). These materials offer superior resilience in highly corrosive, high-temperature, or high-pressure environments, extending the lifespan and performance of plain steel wire mesh and other mesh types in industries like marine, oil & gas, aerospace, and power generation, where extreme conditions demand unparalleled material integrity. The quest for lightweight yet strong solutions is also propelling innovation in expanded metal, offering excellent strength-to-weight ratios for architectural facades, automotive components, and even sophisticated battery technology.

Furthermore, the advent of Industry 4.0 is integrating smart filtration systems for IoT applications. These intelligent systems leverage embedded sensors, real-time data analytics, and cloud connectivity to monitor filtration efficiency, predict maintenance needs, and even self-adjust to optimize performance. This marks a significant leap forward in operational intelligence, reducing downtime, enhancing system reliability, and cutting operational costs for various industrial processes. From smart filters in HVAC systems to predictive maintenance in large-scale industrial filtration plants, the integration of IoT is making wire mesh systems more autonomous and efficient.

Market Insights: A Growing Global Landscape

The global wire mesh market is projected for steady growth, with a Compound Annual Growth Rate (CAGR) estimated around 4-6% over the next five years. This robust expansion is primarily driven by increasing industrialization across emerging economies, especially in Asia and Africa, which necessitates more sophisticated material and filtration solutions. More stringent environmental regulations worldwide are also boosting demand for advanced filtration and separation technologies in water treatment, air purification, and waste management sectors. Additionally, significant infrastructure development projects worldwide, including new roads, bridges, and commercial complexes, rely heavily on wire mesh for reinforcement and security. As urban populations grow and industrial processes become more complex, the need for reliable, high-performance plain steel mesh and other specialized meshes will only intensify.

Emerging focus areas include sustainable manufacturing processes, emphasizing reduced waste, lower energy consumption, and the use of recycled materials. High-performance alloys and composites are continuously being developed for extreme conditions, pushing the boundaries of material science. Automation in mesh production, including robotic welding and advanced weaving machinery, is enhancing efficiency, precision, and consistency. Moreover, customized design solutions are becoming paramount for diverse industrial applications, catering to unique specifications and complex operational environments, moving away from a one-size-fits-all approach.

Leading the Charge: Innovators in Wire Mesh Manufacturing

Anping County Ansheng Wire Meshes Product Co., Ltd. (China)

As a prominent player hailing from Anping County, often referred to as the "Home of Wire Mesh" in China, Anping County Ansheng Wire Meshes Product Co., Ltd. stands out with over three decades of manufacturing excellence. Their extensive product range is a testament to their deep expertise, encompassing high-quality stainless steel wire mesh, various woven wire meshes, and specialized filter meshes. They are particularly renowned for their exceptional plain weave mesh and plain steel wire mesh, which are critical components in countless industrial filtration, separation, and screening applications across industries like oil & gas, chemical, pharmaceutical, and environmental protection.

Ansheng’s unwavering commitment to robust quality control processes is a cornerstone of their operation. Every product, from a basic plain mesh to a complex filter component, undergoes stringent inspections to ensure it meets international standards and precise client specifications. This dedication to quality, combined with strong export capabilities, has enabled them to serve a diverse global clientele, delivering customized solutions that address the unique and often demanding requirements of various industrial applications. Their ability to tailor mesh specifications—including material, wire diameter, mesh count, and weave type—makes them an invaluable partner for projects requiring bespoke plain steel mesh or other specialized designs for optimal performance and durability.

Learn more about their exceptional stainless steel plain weave wire mesh products: Ansheng Stainless Steel Plain Weave Mesh

Other Global Leaders in Wire Mesh

- Bekaert (Belgium): A global technology and market leader in steel wire transformation and coating technologies, Bekaert offers an extensive range of advanced wire mesh solutions for sectors including construction, agriculture, and industrial filtration. Their focus on continuous innovation, high-performance materials, and sustainable solutions positions them at the forefront of the industry, delivering products known for their strength and durability.

- TWP Inc. (USA): Known for its vast inventory of industrial wire mesh, including stainless steel, nickel alloys, and specialty metals, TWP Inc. serves a wide array of industries, from aerospace to medical and automotive. They excel in providing custom fabrication services, ensuring precise mesh solutions for highly specific applications, and are celebrated for their rapid turnaround times and customer service.

- Hebei Jinhai Wire Mesh Co., Ltd. (China): Another significant Chinese manufacturer, Hebei Jinhai specializes in various wire mesh products, including welded wire mesh, hexagonal wire mesh, and expanded metal. They are recognized for their large-scale production capabilities, competitive pricing, and ability to cater to construction, security, and diverse industrial uses worldwide, offering robust and cost-effective solutions.

- GKD – Gebr. Kufferath AG (Germany): GKD is a global leader in technical weaves and filter solutions, known for their high-performance metallic and synthetic meshes. Their products are employed in demanding applications, including architectural design, industrial filtration (e.g., for oil, water, and gas), and process belts, showcasing German engineering precision, innovation, and a strong emphasis on sustainability.

Navigating the Future: Market Outlook & Emerging Opportunities

The trajectory of the wire mesh market points towards continued evolution, driven by relentless advancements in manufacturing technology and a global push for enhanced efficiency and sustainability. Upcoming trends indicate a heightened focus on automation in production lines, leveraging robotics and artificial intelligence to achieve unprecedented levels of precision, speed, and consistency in mesh manufacturing. This not only enhances product quality, particularly for intricate plain weave wire mesh and highly specialized weaves, but also significantly reduces labor costs, minimizes material waste, and allows for greater customization and complex geometries.

Smart manufacturing, a core tenet of Industry 4.0, is transforming how wire mesh is produced and utilized. Integrated sensor technology, real-time data analytics, and predictive maintenance are becoming standard, offering businesses greater control over their supply chains and operational efficiency. Imagine plain mesh filters that report their clogging status proactively, or production lines that self-optimize based on demand fluctuations. Furthermore, sustainability is no longer just a buzzword; it's a critical driver for innovation. Manufacturers are investing heavily in eco-friendly materials, developing energy-efficient production processes, and creating solutions that contribute to circular economy models, such as durable, reusable filtration elements made from advanced plain steel mesh designed for extended lifespans and easy recycling.

For B2B buyers and decision-makers, these trends translate into significant opportunities for competitive advantage. The market is ripe for strategic partnerships with manufacturers who are not only capable of producing high-volume, quality plain mesh but also agile enough to offer bespoke, high-performance solutions tailored to specific, evolving industrial needs. The focus on extreme customization, coupled with sustainable practices and digital integration, will define the competitive edge in the coming years, offering solutions that are not just functional but also future-proof and environmentally responsible.

Strategic Advantages: Key Takeaways for B2B Decision Makers

Investing in high-quality wire mesh from reputable manufacturers is not merely a procurement decision; it's a strategic investment in the reliability, efficiency, and longevity of your operations. The sheer versatility of wire mesh makes it indispensable across a spectrum of industries – from securing perimeters and reinforcing concrete structures in construction, to providing precise filtration in critical manufacturing processes, and even advanced chemical separation in sensitive environments. Selecting the right mesh type, be it a fine plain weave mesh for micro-filtration, a durable plain steel wire mesh for heavy-duty architectural screens, or a custom-engineered solution for unique industrial applications, directly impacts your product quality, operational uptime, and overall project success.

Tips for Adopting or Partnering with Chinese Manufacturers:

- 1. Due Diligence is Key: Thoroughly research potential partners. Look for manufacturers with long-standing experience, transparent operations, and a strong track record of quality and reliability, such as Anping County Ansheng Wire Meshes Product Co., Ltd. Verify their production capacity, export experience, and market reputation.

- 2. Establish Clear Communication: Precise specifications, quality standards, and delivery expectations must be set from the outset. Use detailed technical drawings, international material specifications (e.g., ASTM, DIN), and require pre-shipment sample approvals to minimize misunderstandings, especially for custom plain mesh designs or specialized alloys.

- 3. Focus on Certifications and Quality Assurance: Prioritize manufacturers with internationally recognized certifications like ISO 9001. Request material test reports (MTRs), mill certificates, and third-party inspection reports to ensure adherence to global quality benchmarks for products such as plain weave wire mesh and filtration components.

- 4. Leverage Customization Capabilities: Many Chinese manufacturers, particularly those concentrated in Anping, excel in providing highly customized wire mesh solutions. Don't hesitate to engage them for specific design requirements, unique material combinations, or advanced filtration needs that off-the-shelf products cannot meet.

- 5. Consider On-site Verification: If feasible for large-scale projects, conduct factory audits or send a third-party inspection team to verify production processes, quality control measures, and ethical labor practices, ensuring complete supply chain transparency.

Future-Proofing Your Strategies:

- Embrace Advanced Materials: Stay informed about new alloys, composite meshes, and specialized coatings that offer enhanced performance, longevity, and resistance to extreme conditions for your plain steel mesh and other applications.

- Integrate Digital Solutions: Explore smart filtration systems, IoT-enabled monitoring, and digital twins for proactive maintenance, optimized operational efficiency, and reduced manual intervention in your mesh-based systems.

- Prioritize Sustainability: Align with suppliers who demonstrate a clear commitment to environmentally responsible manufacturing, offering sustainable wire mesh products and processes, thereby contributing to your own corporate social responsibility goals and long-term viability.

The Road Ahead for Wire Mesh Innovation

Wire & Tube Düsseldorf serves as a powerful testament to the dynamic and evolving nature of the global wire mesh market. It’s an essential event for witnessing the innovations that will shape industrial capabilities for years to come, offering a clear roadmap for future developments. The exhibition highlights the critical role manufacturers play in delivering the foundational components that drive everything from precision filtration in advanced industries to robust infrastructural elements and high-performance material separation.

As the industry continues to advance, the emphasis on precision, material innovation, automation, and sustainable practices will only grow. Partnering with experienced and forward-thinking manufacturers, particularly those capable of producing high-quality plain weave mesh, plain mesh, plain steel wire mesh, and other specialized meshes with a focus on customization and cutting-edge technology, will be crucial for businesses looking to maintain a competitive edge and thrive in a rapidly changing global market.

Discover High-Quality Stainless Steel Plain Weave Wire Mesh and More:

Visit Anshengfilterscreen.com TodayExplore their comprehensive range of wire mesh solutions and discover how their decades of expertise can benefit your next project with customized, high-performance products.

Post time: Sep . 24, 2025 09:40