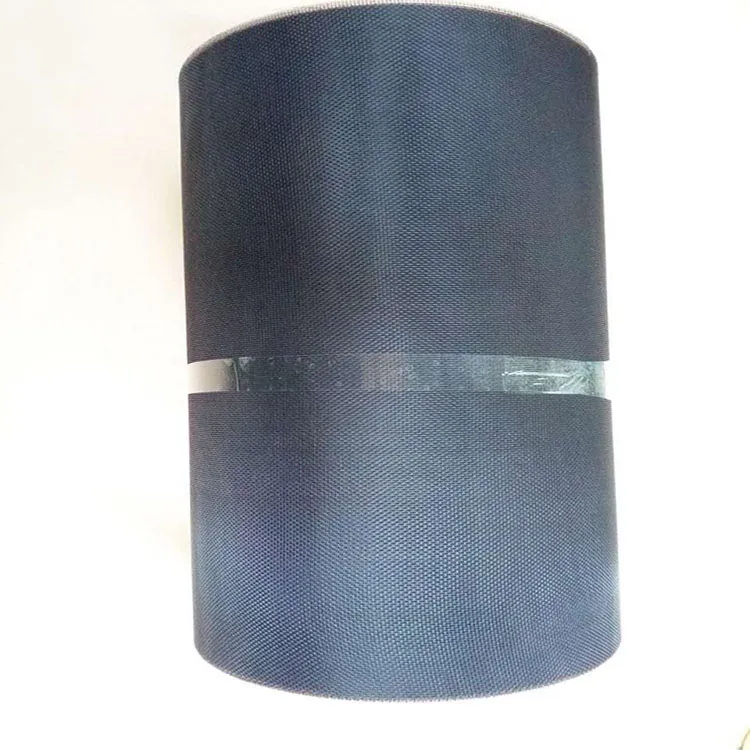

Epoxy Coated Wire Mesh: Durable Solution for Concrete Reinforcement and Industrial Applications

Epoxy coated wire mesh is a high-performance material designed to enhance structural integrity in construction and industrial settings. Manufactured by Anping County Ansheng Wire Meshes Product Co., Ltd., this product combines the strength of steel wire with a protective epoxy coating, offering superior corrosion resistance and durability. Whether used in concrete reinforcement, fencing, or industrial machinery, epoxy coated welded wire mesh provides a reliable solution for modern engineering challenges.

Understanding Epoxy Coated Wire Mesh

Epoxy coated wire mesh is a specialized form of epoxy coated mesh created by applying a layer of epoxy resin to the surface of steel wire. This coating acts as a barrier against moisture, chemicals, and environmental stressors, significantly extending the lifespan of the product. The manufacturing process involves precise temperature control and high-quality materials to ensure uniform coverage and adhesion. The result is a material that maintains its structural properties while resisting rust, UV degradation, and mechanical wear.

Key technical specifications of epoxy coated wire mesh for concrete include:

- Wire diameter: 0.5mm - 5.0mm (customizable)

- Coating thickness: 150-300 microns

- Chemical resistance: Resists acids, alkalis, and solvents

- Temperature range: -40°C to 80°C

- Surface finish: Smooth, uniform epoxy layer

Market Demand and Industry Challenges

The construction and manufacturing industries face persistent challenges related to material degradation. Traditional steel mesh often succumbs to corrosion, leading to costly repairs and structural failures. Epoxy coated welded wire mesh addresses these issues by providing a long-term solution that maintains performance under harsh conditions. According to industry reports, the demand for corrosion-resistant materials has grown by 12% annually, driven by infrastructure development and the need for sustainable building practices.

Key advantages of epoxy coated mesh over conventional alternatives include:

- 3-5 times longer lifespan compared to uncoated steel

- Reduced maintenance costs and downtime

- Improved safety through enhanced structural stability

- Compliance with international quality standards (e.g., ISO 9001)

Company Expertise and Technological Innovation

As a leading manufacturer in the wire mesh industry, Anping County Ansheng Wire Meshes Product Co., Ltd. has established itself as a trusted provider of epoxy coated wire mesh solutions. With over 20 years of experience, the company combines advanced technology with meticulous craftsmanship to deliver products that meet global standards. Their state-of-the-art production facilities utilize automated coating systems and rigorous quality control processes to ensure consistency and performance.

The company's commitment to innovation is evident in its R&D capabilities. By investing in material science research, Anping County Ansheng Wire Meshes Product Co., Ltd. has developed proprietary coating formulations that offer superior adhesion and flexibility. This technical expertise enables them to customize solutions for diverse applications, from epoxy coated wire mesh for concrete to specialized industrial filters and protective barriers.

Proven Performance and Customer Testimonials

Customers across various sectors have reported significant improvements in project outcomes using epoxy coated wire mesh. A major infrastructure project in Southeast Asia, for example, utilized epoxy coated welded wire mesh for bridge reinforcement, resulting in a 40% reduction in maintenance costs over a 10-year period. Similarly, a manufacturing plant in the Middle East implemented epoxy coated mesh for conveyor belt systems, achieving a 60% increase in equipment lifespan.

Client feedback highlights the product's reliability and value:

- "The epoxy coating has completely eliminated rust issues in our concrete structures. This has saved us thousands in repairs." – John M., Construction Manager

- "Anping County Ansheng Wire Meshes Product Co., Ltd. provided tailored solutions that met our strict quality requirements." – Maria S., Industrial Engineer

Implementation and Customization Options

Proper installation is critical to maximizing the benefits of epoxy coated wire mesh. The company offers comprehensive guidance, including:

- Technical manuals with step-by-step installation procedures

- On-site support for large-scale projects

- Customized mesh configurations based on project specifications

- Variable mesh sizes (e.g., 10x10mm, 20x20mm)

- Specialized coatings for extreme environments

- Integrated reinforcement systems for concrete structures

Environmental Safety and Compliance

Epoxy coated wire mesh is designed with environmental responsibility in mind. The coating process adheres to strict eco-friendly standards, minimizing volatile organic compound (VOC) emissions. The product is also free from hazardous substances, making it safe for use in residential, commercial, and industrial settings. Anping County Ansheng Wire Meshes Product Co., Ltd. holds certifications such as RoHS and REACH, ensuring compliance with global environmental regulations.

Logistics and Packaging Solutions

To meet the needs of bulk purchasers, epoxy coated wire mesh is available in various packaging options, including:

- Standard pallets for warehouse storage

- Customized crates for delicate or large-format mesh

- Moisture-proof packaging for long-term preservation

Comprehensive Customer Support

Anping County Ansheng Wire Meshes Product Co., Ltd. offers dedicated support to ensure customer satisfaction. Their services include:

- 24/7 technical assistance for product inquiries

- On-site training for installation and maintenance

- Warranty programs covering material and manufacturing defects

Contact Us for Expert Solutions

For more information about epoxy coated wire mesh or to request a customized quote, please reach out to Anping County Ansheng Wire Meshes Product Co., Ltd. through the following channels:

- Phone: +86-312-6666666

- Email: sales@anshengfilterscreen.com

- Website: www.anshengfilterscreen.com

- Online Chat: Available on the company website

Conclusion

Epoxy coated wire mesh from Anping County Ansheng Wire Meshes Product Co., Ltd. delivers exceptional durability, corrosion resistance, and versatility. By choosing this product, businesses can reduce long-term costs, enhance structural safety, and meet environmental standards. Explore the full range of epoxy coated wire mesh solutions today.

FAQ

Q: What are the primary applications of epoxy coated wire mesh?

A: It is widely used in concrete reinforcement, industrial fencing, machinery protection, and as a component in concrete structures.

Q: How does the epoxy coating improve product lifespan?

A: The coating prevents moisture and chemical exposure, which are the main causes of steel degradation.

Q: Can the mesh be customized for specific projects?

A: Yes, Anping County Ansheng Wire Meshes Product Co., Ltd. offers tailored solutions for unique requirements.

Q: What certifications does the product have?

A: The product complies with ISO 9001, RoHS, and REACH standards.

Q: How is the product shipped to international customers?

A: The company provides global logistics support with customizable packaging options.

Post time: Jul . 21, 2025 02:00