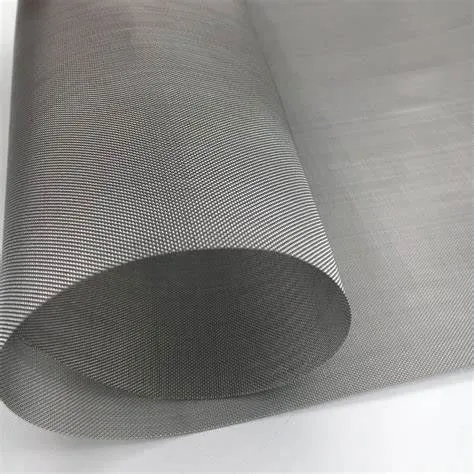

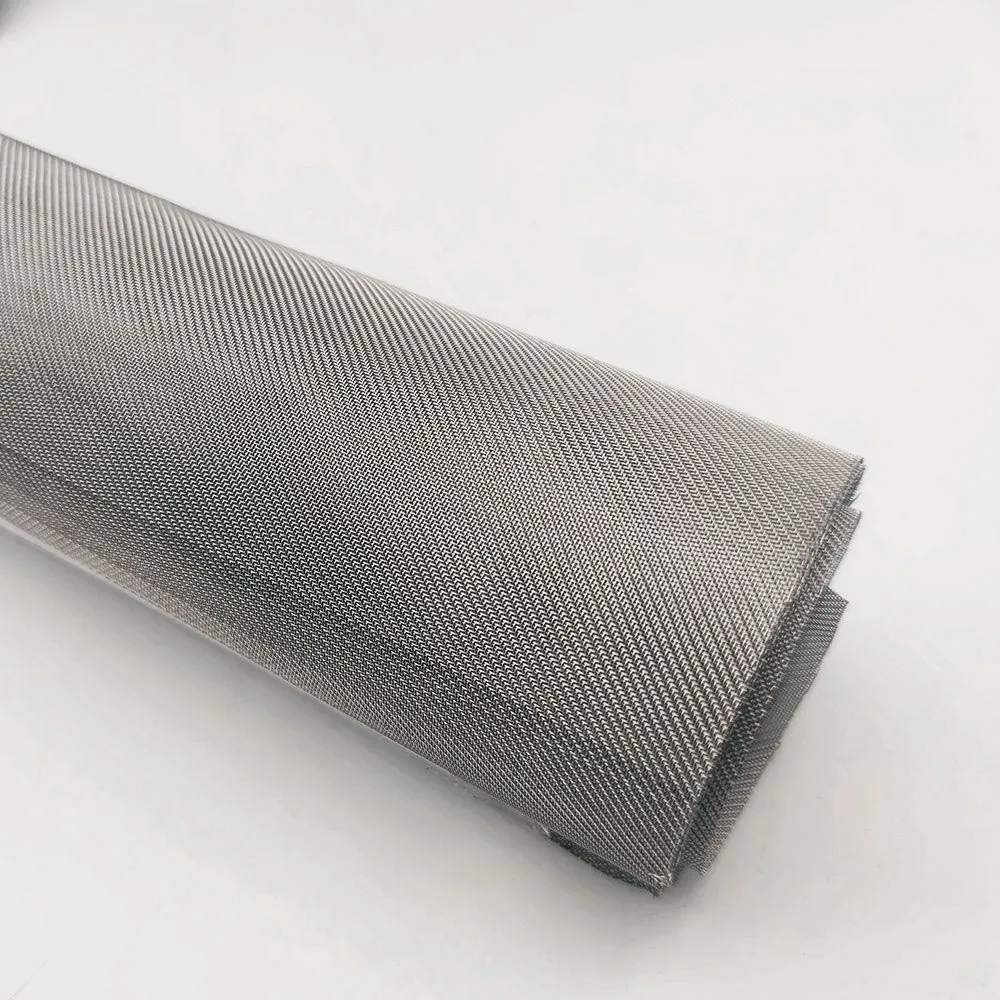

Nickel Twill Weave Wire Mesh: High-Quality Stainless Steel Mesh Fabric for Industrial Applications

Discover the superior performance of Nickel Twill Weave Wire Mesh from Anping County Ansheng Wire Meshes Product Co., Ltd.. This advanced stainless steel mesh fabric combines durability, precision, and versatility to meet the demands of modern industrial applications.

Product Overview

The Nickel Twill Weave Wire Mesh is a specialized stainless steel mesh fabric designed for applications requiring high tensile strength, corrosion resistance, and precise filtration capabilities. Manufactured using advanced weaving techniques, this product features a unique twill weave pattern that enhances its structural integrity while maintaining optimal airflow and particle retention. Explore the product details here.

Key Features and Benefits

- Durability: Constructed from high-grade stainless steel, the mesh resists wear, tear, and environmental degradation, ensuring long-term performance in harsh conditions.

- Corrosion Resistance: The stainless steel composition provides exceptional resistance to rust, chemicals, and moisture, making it ideal for industrial and outdoor applications.

- Precision Engineering: The twill weave pattern ensures consistent mesh openings, offering reliable filtration and separation capabilities for various materials.

- Flexibility: Available in multiple sizes and configurations, the mesh adapts to diverse industrial needs, from construction to manufacturing.

Technical Specifications

| Parameter | Details |

|---|---|

| Material | Stainless Steel (304/316) |

| Weave Pattern | Nickel Twill Weave |

| Mesh Size | 10-100 mesh (customizable) |

| Thickness | 0.1-2.0 mm |

| Surface Treatment | Polished, Electroplated, or Coated (as per requirements) |

Industrial Applications

The Nickel Twill Weave Wire Mesh is widely used in the following sectors:

- Construction: For reinforcing concrete structures and creating durable fencing systems.

- Manufacturing: As a filter medium in food processing, pharmaceuticals, and chemical industries.

- Environmental: In air and water filtration systems to remove contaminants efficiently.

- Automotive: For heat shields, exhaust systems, and custom components requiring high-temperature resistance.

Market Demand and Industry Challenges

The demand for high-performance mesh products has surged due to the need for reliable materials in critical applications. Traditional mesh solutions often struggle with issues like corrosion, inconsistent filtration, and limited durability. The Nickel Twill Weave Wire Mesh addresses these challenges by offering a combination of advanced materials and precise engineering, ensuring optimal results in even the most demanding environments.

Company Expertise and Innovation

As a leading manufacturer in the wire mesh industry, Anping County Ansheng Wire Meshes Product Co., Ltd. has established itself as a trusted provider of high-quality stainless steel mesh fabrics. With over a decade of experience, the company invests heavily in R&D to stay at the forefront of technological advancements. Their state-of-the-art facilities and skilled workforce ensure that every product meets the highest standards of quality and performance.

Customer Testimonials

"The Nickel Twill Weave Wire Mesh has significantly improved our filtration efficiency. The product's durability and precision have exceeded our expectations." – John D., Manufacturing Manager

"We've been using Anping County Ansheng's mesh for several years, and their commitment to quality is unmatched. Their technical support is also exceptional." – Emily R., Environmental Engineer

Usage Guidelines and Customization

To maximize the performance of the Nickel Twill Weave Wire Mesh, follow these guidelines:

- Installation: Ensure proper alignment and secure fastening to prevent deformation under load.

- Maintenance: Regularly inspect the mesh for signs of wear and clean it to maintain optimal filtration efficiency.

- Customization: Contact Anping County Ansheng Wire Meshes Product Co., Ltd. for tailored solutions to meet specific project requirements.

Environmental and Safety Compliance

All Nickel Twill Weave Wire Mesh products comply with international safety and environmental standards, including ISO 9001 and RoHS. The stainless steel material is non-toxic and recyclable, ensuring minimal environmental impact throughout its lifecycle.

Packaging and Delivery

The mesh is packaged in moisture-proof, stackable containers to protect against damage during transit. For large orders, customized packaging options are available to suit specific logistical needs. Contact us for detailed shipping information and delivery timelines.

After-Sales Support and Technical Assistance

At Anping County Ansheng Wire Meshes Product Co., Ltd., we prioritize customer satisfaction. Our dedicated support team offers:

- 24/7 technical咨询 for product installation and troubleshooting.

- On-site training for large-scale implementations.

- Warranty and replacement services for defective products.

Conclusion

The Nickel Twill Weave Wire Mesh from Anping County Ansheng Wire Meshes Product Co., Ltd. is a reliable solution for industries seeking durable, high-performance mesh fabric. With its advanced design, corrosion resistance, and versatility, this product is an ideal choice for modern industrial applications. Discover more about our products today.

Frequently Asked Questions (FAQ)

Q1: What is the primary material used in the Nickel Twill Weave Wire Mesh?

A: The mesh is made from high-grade stainless steel (304/316), ensuring excellent durability and corrosion resistance.

Q2: Can the mesh be customized to specific requirements?

A: Yes, we offer customization options for mesh size, thickness, and surface treatment to meet your unique needs.

Q3: What industries benefit most from this product?

A: The mesh is widely used in construction, manufacturing, environmental systems, and automotive industries.

Q4: How is the product packaged for shipping?

A: It is packaged in moisture-proof, stackable containers to ensure safe transportation and storage.

Q5: What kind of after-sales support do you provide?

A: We offer 24/7 technical support, on-site training, and warranty services to ensure customer satisfaction.

Post time: Jul . 21, 2025 02:00