Multi-Layer Mesh With Welding Spots: a practical guide from the shop floor

If you spend your days around process lines and strainer housings, you already know the quiet workhorses keeping fluids honest: wire mesh discs. I’ve watched these parts evolve from simple single-ply cutouts to high-precision, multi-layer assemblies with tidy weld spots and zero burr drama. And, to be honest, once you dial in the stack-up and weave, uptime goes up.

What’s trending? Short answer: multi-layer stacks (1–635 mesh combinations), tighter QA, and faster customization cycles. Multi-layer welded designs are favored over sintered for applications needing quick prototyping, lower heat history, or where replacing just the disc—not the housing—saves the day. Many customers say they appreciate the clean edges and repeatable pore structure.

Core specs at a glance

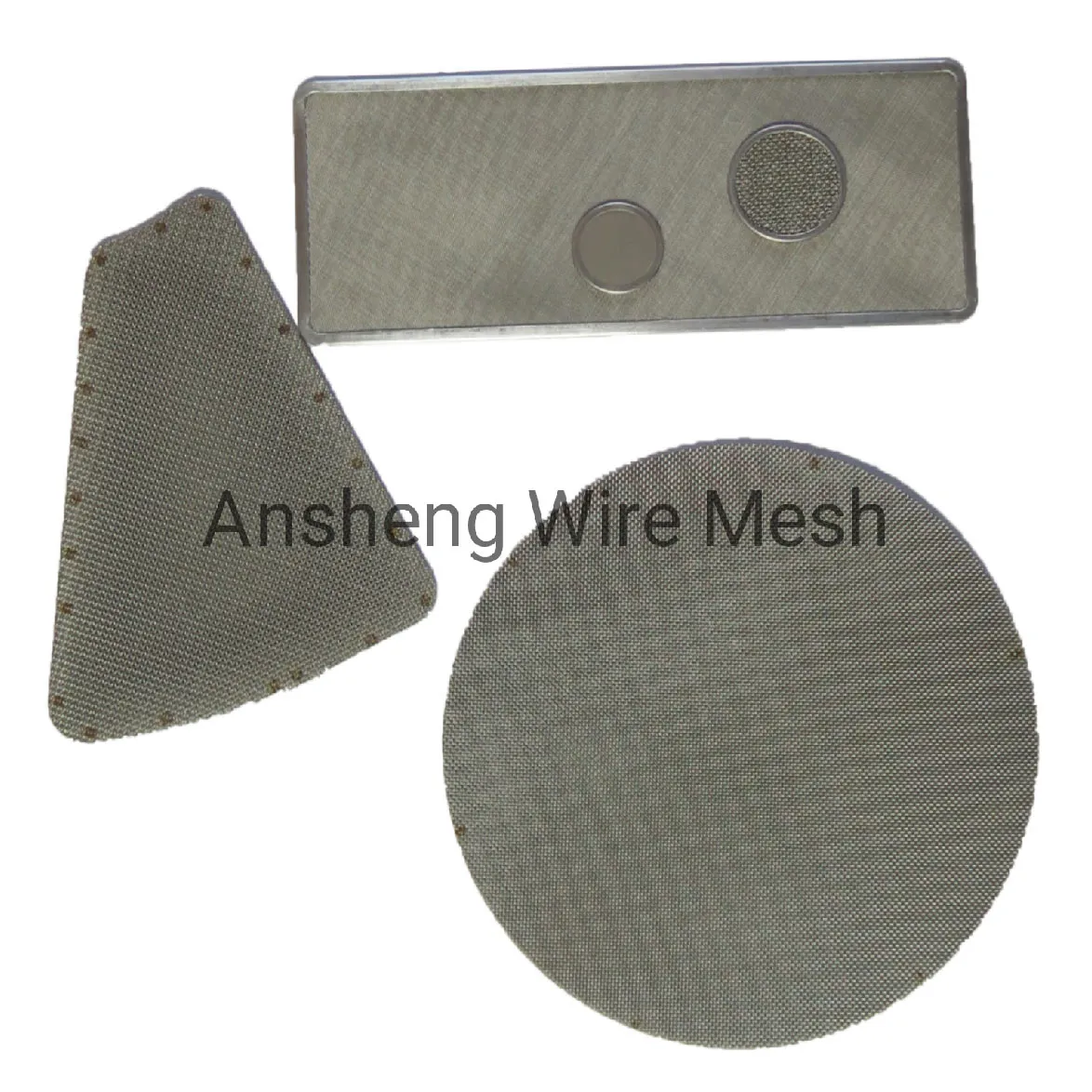

Product: Multi-Layer Mesh With Welding Spots (origin: No.346 Xinying East Street, Anping County, Hebei, China). Materials include SS304/201/316/316L, Nickel (N6/N4/200), low-carbon steel, and galvanized. Weaves: plain, twill, and dutch (incl. reverse). Shapes: circle, square, oval, kidney, rectangle, irregular. Sizes from 30 mm to ≈1 m diameter/side.

| Parameter | Typical Range | Notes (real-world use may vary) |

|---|---|---|

| Mesh Count | 1–635 mesh | Layered stacks tune micron rating and flow |

| Disc Diameter/Side | 30 mm to ≈1000 mm | Tight OD tolerance ±0.10–0.20 mm typical |

| Layers | 2–5+ layers | Weld spots for stability; optional rim/edge wrap |

| Thickness | ≈0.20–1.8 mm | Depends on wire dia. and layer count |

| Material Options | SS304/316/316L, Nickel, LC Steel, Galv. | 316L for corrosives; Nickel for high-temp or caustic media |

Manufacturing flow (how the good ones are made)

- Material prep: certified wire cloth per ASTM E2016 and ISO 9044; COAs archived.

- Cutting: die or laser; heat-minimized to avoid edge hardening.

- Stacking: specified layer order (e.g., support/twill/dutch cap).

- Spot welding: controlled energy for firm joints without warp.

- Deburr and edge finishing: smooth, burr-free, uniform OD.

- Cleaning: ultrasonic, oil-free; serialized bagging.

- Inspection: aperture check (optical), dimensional gauge, flatness, visual.

Typical service life: 6–24 months in neutral fluids; 316L and Nickel stacks often exceed 24 months in well-controlled systems. Salt-spray validation for galvanized/LC steel per ASTM B117, when requested.

Where wire mesh discs shine

Common use cases: polymer melt filters, hydraulic return lines, chemical dosing lances, gas spargers, food oil polishing, and pilot lines. Advantages include stable pore geometry, easy change-out, and excellent pressure drop-to-capture balance when dutch weaves are layered over a sturdy support.

Quality, tests, and a quick data point

Standards referenced in procurement: ASTM E2016 (wire cloth), ISO 9044 (technical requirements/tests). Many factories operate to ISO 9001 systems. A recent 3-layer 316L dutch/twill/support disc, Ø50 mm, delivered aperture verification within ±6% of nominal; delta-P at 30 L/min water was 0.12 bar at 23°C (bench rig). Flatness stayed under 0.3 mm.

Vendor comparison (what buyers usually weigh)

| Vendor | MOQ | Lead Time | Customization | Testing/Docs | Price Level |

|---|---|---|---|---|---|

| Ansheng Filter Screen | 50–200 pcs ≈ | 7–15 days typical | Shapes, layers, weave mix, rim wraps | Dimensional + aperture report; ISO refs | Competitive |

| Global OEM Supplier | 500+ pcs | 3–5 weeks | Broad; strong PPAP options | Full QA packs; often ISO 9001 | Mid–High |

| Local Fabricator | 10–100 pcs | 2–10 days | Fast protos; limited weaves | Basic COA; limited metrology | Variable |

Customization and quick case notes

- Custom shapes: oval and kidney-shaped wire mesh discs for legacy housings.

- Layer recipes: dutch over twill for finer capture with sane pressure drop.

- Edge wraps: stainless rim to prevent fray in high-vibration skids.

Case A (food oil): swapped single-ply 80 mesh for a 3-layer dutch/twill/support; change-out interval improved from 2 to 6 weeks, complaint rate dropped sharply. Case B (solvents): Nickel stack replaced corroding carbon steel; unplanned downtime went to near-zero over 9 months. It seems that consistent weld quality matters more than people admit.

Citations

- ASTM E2016 – Standard Specification for Industrial Woven Wire Cloth, ASTM International.

- ISO 9044 – Industrial Woven Wire Cloth: Technical requirements and tests, International Organization for Standardization.

- ASTM B117 – Standard Practice for Operating Salt Spray (Fog) Apparatus, ASTM International.

- ISO 9001:2015 – Quality management systems — Requirements, International Organization for Standardization.

Post time: Sep . 30, 2025 17:55