Multi-Layer Mesh With Welding Spots: a field note from the factory floor

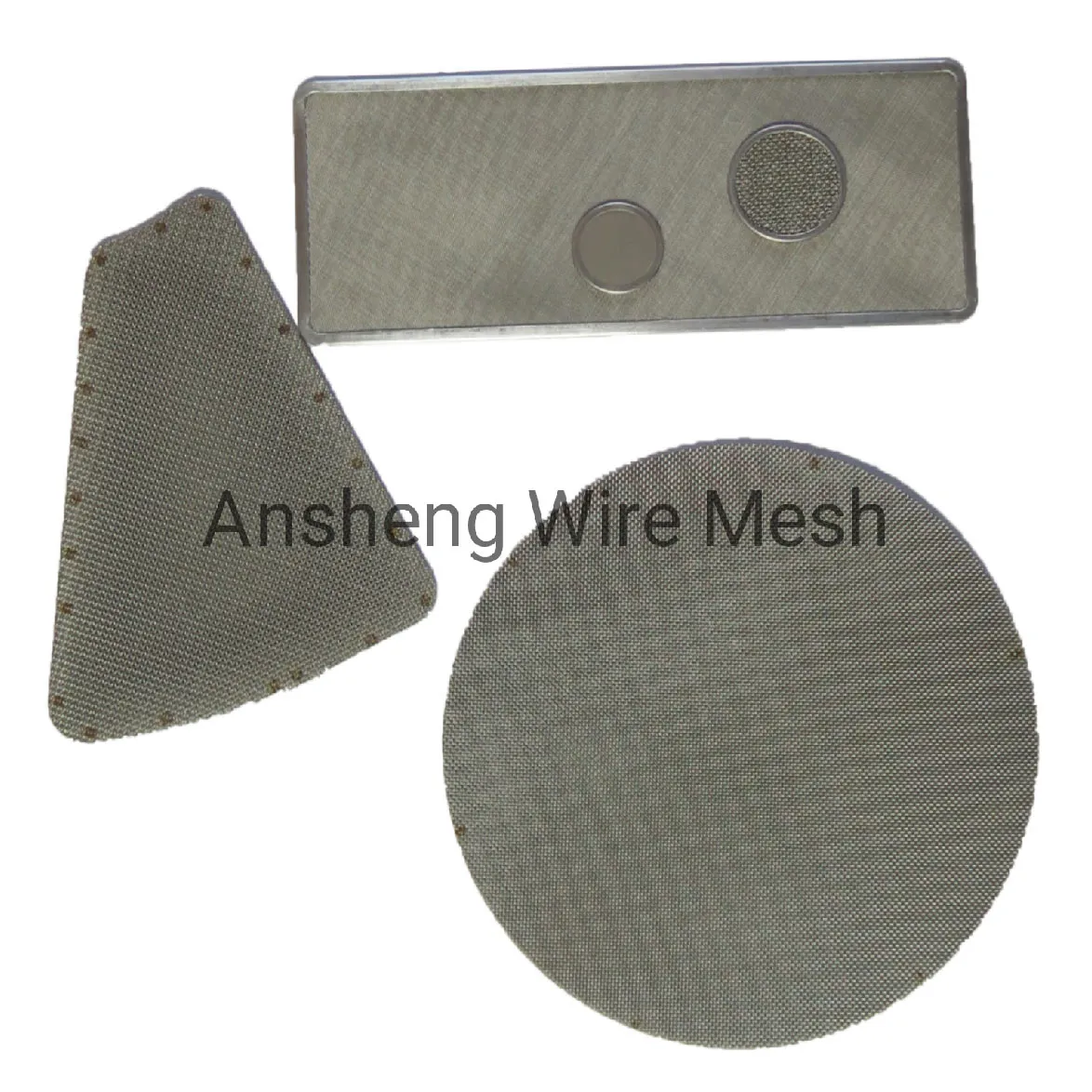

If you work in filtration, extrusion, or even small-batch biotech, you already know the quiet heroes in your line: [wire mesh discs]. I’ve watched teams debate micron ratings like it’s the draft. And honestly, the simple stuff—flatness, clean edges, repeatable welds—often decides uptime. That’s why this multi-layer, spot-welded construction has been trending up. It’s not flashy, but it’s reliable.

What’s moving the market

Three things: tighter ESG compliance (so traceable alloys and cleaner finishing), rising polymer melt-purity targets, and more modular lines that swap discs fast. Many customers say spot-welded stacks hit the sweet spot—rigid enough for pressure, yet cost-effective versus sintered laminates.

Core specifications (quick view)

| Item | Details (≈ real-world use may vary) |

|---|---|

| Materials | SS304, SS201, SS316, SS316L, Nickel N6/N4/200, low-carbon steel, galvanized |

| Mesh range | 1–635 mesh; typical filtration ≈ 5–300 μm |

| Size / Shape | 30 mm–1 m; circle, square, oval, kidney, rectangle, irregular |

| Weaves | Plain, twill, Dutch (incl. reverse Dutch for melt screens) |

| Build | Multi-layer stack with firm spot welds; smooth edges, burr-free |

| Tolerances | OD/ID ±0.2–0.5 mm typical; flatness ≤0.3 mm/100 mm |

| Temp/chem | Up to ≈ 400°C (316L); corrosion per ASTM B117 >200 h (5% NaCl), material dependent |

How it’s made (process flow)

- Material selection: certified SS/Nickel coils with heat numbers and MTRs.

- Weaving: plain/twill/Dutch per ASTM E2016 and ISO 9044.

- Stacking & spot welding: layer count per spec; controlled heat to avoid warping.

- Trimming & deburring: laser or die-cut; edges smoothed, burr-free.

- Cleaning: ultrasonic degrease; optional passivation (ASTM A967) for stainless.

- Testing: mesh count, micrometer thickness, pressure drop (ISO 3968 proxy rig), bubble-point screening (ASTM F316, if requested), salt spray (ASTM B117).

- Packing: cleanroom bagging available; full traceability labels.

Field data I’ve seen: ΔP at 50 L/min through a 100 μm, 3-layer stack ≈ 6–9 kPa; collapse pressure >0.8 MPa on 50 mm discs; service life 6–24 months depending on DP cycling, media, and CIP frequency.

Where they work well

- Polymer extrusion screens (PE, PP, PET); die protection.

- Hydraulic and lube skids; pump suction guards.

- Petrochem and solvent filtration (choose 316L or Nickel for chemistry).

- Food & beverage prefiltration; steam traps (verify material compliance).

- Pharma utilities; bioprocess vent protection (clean-edges help a lot).

- Water treatment: RO pre-screens, strainer baskets.

Why multi-layer spot-welded [wire mesh discs]?

Rigidity, consistent pore geometry, and quick changeouts. To be honest, sintered laminates still win at the ultra-fine end, but these discs punch above their weight on cost-per-run.

Vendor snapshot (what buyers compare)

| Criteria | Ansheng (Multi-Layer, Spot-Welded) | Generic Importer | Local Fabricator |

|---|---|---|---|

| Traceability | Heat-numbered coils, MTRs | Varies | Good, limited alloy options |

| Edge quality | Burr-free, smooth | Inconsistent | Good |

| Lead time | Fast for standard sizes | Uncertain | Fast, small batches |

| Certs | ISO 9001; RoHS/REACH on request | Limited | Varies |

Customization that actually helps

- Layer count/sequence (e.g., Dutch upstream, plain support).

- Rim options: bare edge, folded rim, or external ring.

- CIP-friendly passivation; solvent cleaning for polymer lines.

- Kitted sets by mesh gradient; laser-etched IDs.

[wire mesh discs] from Ansheng are produced in Anping (No.346 Xinying East Street, Hebei, China)—the town where half the world’s wire cloth seems to come from. Small digression: that cluster means quicker access to odd shapes and nickel grades when you’re in a pinch.

Real-world wins

- Polymer plant cut screen changeovers by ≈ 2.5× using 4-layer Dutch/plain stack; gel defects fell measurably.

- Hydraulic OEM stabilized cold-start ΔP spikes; scrap rate down 18% after switching to deburred discs.

Standards and compliance: ASTM E2016 and ISO 9044 for woven cloth, ISO 3968 for pressure-drop methods, ASTM B117 for corrosion, and ISO 9001 QMS. Ask for data packs—many buyers do, and it speeds approvals.

References

- ASTM E2016/E2016M – Standard Specification for Industrial Woven Wire Cloth.

- ISO 9044 – Industrial woven wire cloth: nominal sizes of apertures and wire diameters.

- ISO 3968 – Hydraulic fluid power filters: evaluation of pressure drop versus flow.

- ASTM B117 – Standard Practice for Operating Salt Spray (Fog) Apparatus.

Post time: Oct . 06, 2025 13:20