Welded Wire Mesh: insider notes, real specs, and what to check before you buy

If you’re scanning the market for Welded Mesh For Sale, here’s the short version: demand is up, lead times wobble with steel prices, and customization matters more than ever. From fencing to filtration guards, the category has quietly become the workhorse of industrial and construction supply. And yes, I’ve seen buyers overpay for generic panels that fail salt-spray tests. Let’s avoid that.

What it is and why people prefer it

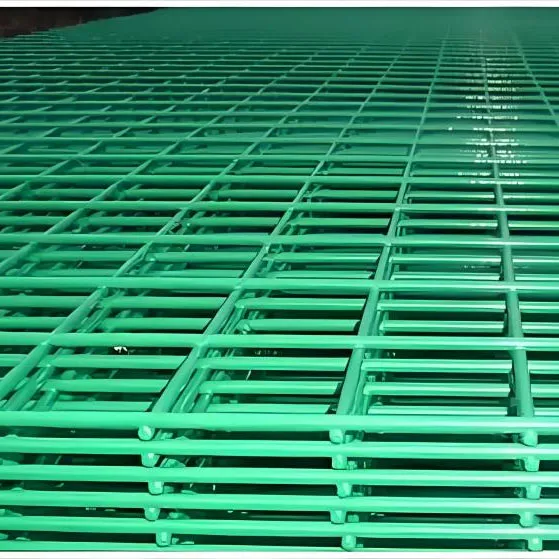

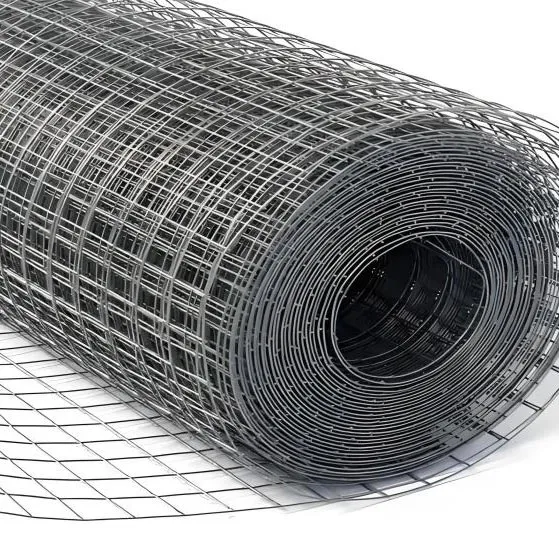

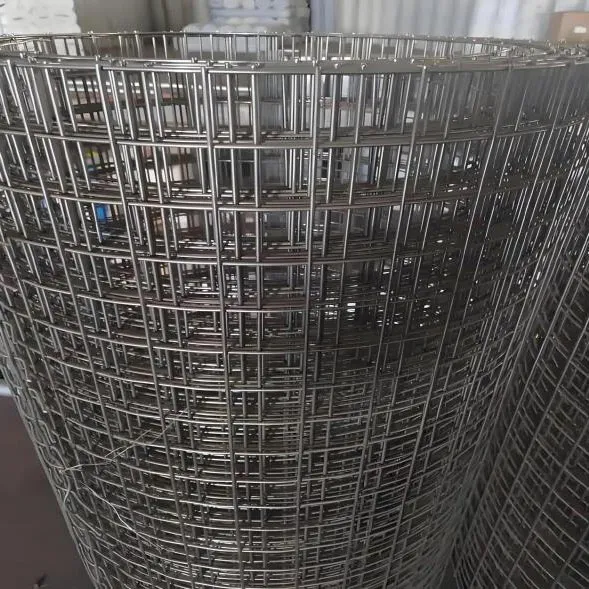

Welded wire mesh is a rigid grid formed by resistance-welding cross wires at each intersection. Compared with woven mesh, it stays flat, doesn’t unravel if cut, and handles impact better. Many customers say it “just installs faster,” which tracks with what installers report on sites. To be honest, rigidity is the unsung hero here.

Process flow (how good mesh is actually made)

- Materials: low-carbon steel (Q195/SAE 1008), galvanized steel (ASTM A641), or stainless (304/316 per ASTM A580).

- Wire drawing and straightening: diameter control to ±0.02 mm (real-world use may vary).

- Resistance spot welding: parameters tuned to avoid HAZ brittleness; double-check weld nugget size.

- Flattening and cutting: panels typically 1×2 m, 1.2×2.4 m, or custom.

- Coatings: hot-dip galvanizing (ISO 1461), electro-galv (EN 10244-2), or PVC coating for coastal jobs.

- Testing: tensile per ASTM A370, weld shear per ASTM A1064, coating mass per ISO 1461; optional salt-spray (ASTM B117).

Product snapshot (specs you’ll actually use)

| Parameter | Typical Range | Notes |

|---|---|---|

| Material | Low-carbon, GI, SS304/316 | Pick SS316 for marine/corrosive areas |

| Wire dia | 1.0–6.0 mm ≈ | Thicker wire = stronger but heavier |

| Aperture | 12×12 mm to 100×100 mm | Tighter apertures for cages/guards |

| Panel size | 1×2 m, 1.2×2.4 m, custom | Custom trims reduce on-site cuts |

| Coating mass | Zinc 50–275 g/m² ≈ | Higher for coastal or fertilizer plants |

| Weld shear | > 400–900 N (gauge-dependent) | Test per ASTM A1064; ask for data |

| Service life | 5–20+ years | Climate and coating drive lifespan |

Where it’s used (and what buyers report)

Construction reinforcement, perimeter fencing, animal enclosures, HVAC/vent guards, machine guarding, storage partitions, and even solar farm perimeters. One facilities manager told me their PVC-coated mesh outlived the posts—surprising, but the zinc + PVC combo can be tough.

Vendor comparison (quick reality check)

| Vendor | Origin | Certs | Customization | Lead Time | Notes |

|---|---|---|---|---|---|

| Ansheng Filter Screen | No.346 Xinying East St., Anping, Hebei, China | ISO 9001; coating per ISO 1461 | Wire dia, aperture, coatings, cut-to-size | ≈ 10–20 days | Factory pricing; test reports on request |

| Local distributor | Regional warehouse | Varies | Limited stock sizes | Immediate for in-stock | Fast replacement, higher price/ft² |

| Imported brand (generic) | Mixed | Claimed; verify | Often standard only | ≈ 25–45 days | Check weld shear and zinc mass |

Case notes and test data

- Solar farm fence, coastal zone: hot-dip galvanized, zinc ≈ 275 g/m²; ASTM B117 salt-spray 240 h with no red rust; estimated life 12–18 years.

- Poultry facility: PVC-coated 2.5 mm wire, 25×25 mm aperture; washdowns weekly; weld shear > 600 N average.

- Aggregate plant guard: SS304, 3.0 mm wire; zero coating loss; higher upfront, minimal maintenance.

Buying tips (so you don’t regret it later)

Specify wire diameter, aperture, panel size, coating mass, and target weld shear. Ask for mill certificates and coating/test reports. For coastal or chemical exposure, don’t skimp—either higher zinc or stainless. And when you see Welded Mesh For Sale deals that look too good, check the weld nugget and straightness first.

If you need engineered support or custom apertures, Welded Mesh For Sale from specialist factories (like Ansheng in Anping) can be tailored without crazy MOQs.

Standards and references

- ASTM A1064/A1064M — Standard Specification for Steel Wire and Welded Wire Reinforcement.

- ISO 1461 — Hot dip galvanized coatings on fabricated iron and steel articles.

- EN 10244-2 — Steel wire and wire products, zinc or zinc-alloy coated.

- ASTM B117 — Standard Practice for Operating Salt Spray (Fog) Apparatus.

Post time: Nov . 07, 2025 17:45