twill weave mesh, twill weave wire mesh, twill mesh is a key solution in the manufacturing industry, specifically within Fabricated metal products and Manufacturing of metal wire ropes and their products. This article explores how Anping County Ansheng Wire Meshes Product Co., Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- twill weave mesh, twill weave wire mesh, twill mesh Overview

- Benefits & Use Cases of twill weave mesh, twill weave wire mesh, twill mesh in Manufacturing of metal wire ropes and their products

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on twill weave mesh, twill weave wire mesh, twill mesh from Anping County Ansheng Wire Meshes Product Co., Ltd.

twill weave mesh, twill weave wire mesh, twill mesh Overview

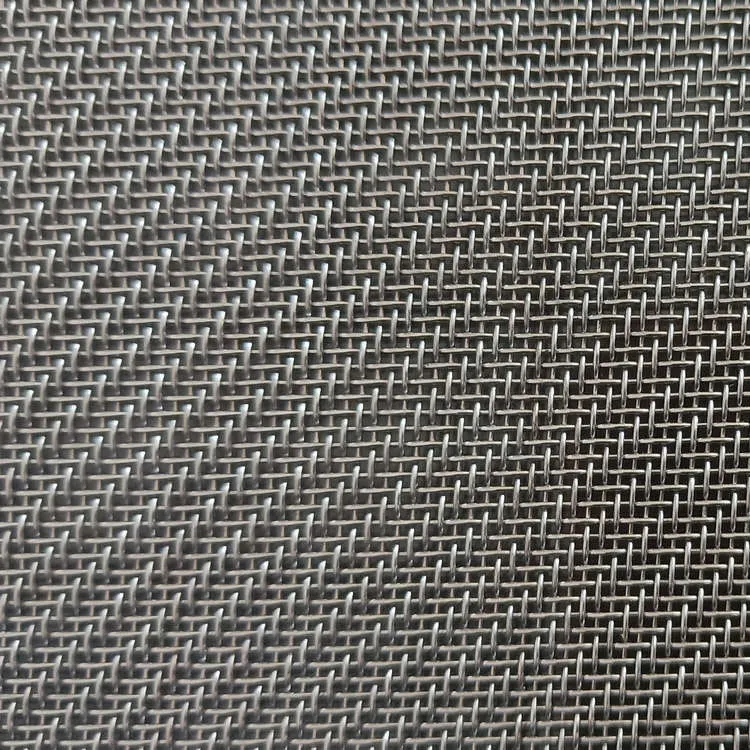

In a twill weave, each warp and weft wire alternately passes over two and under two wires, forming a diagonal pattern. Compared with plain weave, twill weave mesh allows the use of relatively thicker wire at higher mesh counts, delivering a strong, precise, and stable filtration medium. For B2B buyers in fabricated metal products—especially those producing metal wire ropes and related products—twill weave wire mesh is indispensable in lubrication filtration, acid pickling baskets, polymer extrusion screens, and protective screening around drawing and stranding lines.

Typical specifications include stainless steel grades 304, 304L, 316, and 316L; mesh counts from 20–400 mesh; wire diameters from approximately 0.02–0.60 mm; widths up to 2,000 mm; and roll lengths commonly 30 m (custom on request). Aperture uniformity and surface stability make twill mesh suitable for high-pressure, high-temperature, and corrosive environments common in wire rope processing. Anping County Ansheng Wire Meshes Product Co., Ltd. manufactures and supplies stainless steel twill weave wire mesh to tight dimensional tolerances, offering cut-to-size sheets, discs, and multi-layer packs tailored to production lines. With application-driven engineering support, Ansheng helps integrate mesh specifications into filtration, separation, and guarding steps that directly affect throughput and product quality.

Benefits & Use Cases of twill weave mesh, twill weave wire mesh, twill mesh in Manufacturing of metal wire ropes and their products

For wire rope manufacturers, process reliability is everything. Twill weave mesh supports stable filtration of wire-drawing lubricants and coolants, helping maintain clean dies and consistent surface finish on wire. It is also used in acid pickling baskets and rinse stages, where stainless steel twill weave wire mesh withstands corrosive media and thermal cycling. In polymer or resin-coated wire production, twill mesh serves as extrusion screens and multi-layer filter packs, securing fine particulate retention with robust mechanical strength. Further, twill mesh is commonly applied as protective guards and debris screens around stranding, closing, and spooling equipment, providing impact resistance with precise open area.

Key advantages for B2B operations include high strength-to-aperture ratio, excellent dimensional stability under load, smooth surface for easy cleaning, and consistent aperture for predictable filtration performance. Compared with plain weave, twill weave mesh can achieve finer ratings at comparable or greater mechanical strength, extending service intervals in demanding stages. Anping County Ansheng Wire Meshes Product Co., Ltd. brings deep sector expertise with options such as calendaring for tighter thickness tolerance, ultrasonic cleaning for low contamination, edge welding, spot welding, and custom slitting. Whether you need single-layer rolls or layered assemblies, Ansheng aligns mesh specifications with target micron ratings, pressure profiles, and equipment footprints across wire-drawing and stranding lines.

Cost, Maintenance & User Experience

Total cost of ownership with twill weave mesh is driven by service life, cleaning cycles, and change-out frequency. Thanks to its robust diagonal weave, twill mesh resists deformation and rupture during pressure fluctuations, reducing unplanned downtime. Stainless steel construction supports repeated maintenance methods—backflushing, ultrasonic cleaning, solvent rinsing, or CIP-type processes—so screens and packs can be returned to service without loss of integrity. Over time, this extends replacement intervals and stabilizes operating costs in lubricant filtration and extrusion applications.

Procurement teams in the fabricated metal products sector value predictable quality, consistent roll-to-roll tolerance, and rapid replenishment. Customers of Anping County Ansheng Wire Meshes Product Co., Ltd. report smoother start-ups and fewer line stoppages when mesh aperture uniformity and thickness are held tight, which in turn helps maintain die life and surface quality in drawn wire. Ansheng supports cost control through:

- Application-specific mesh selection to balance micron rating, flow, and strength

- Cut-to-size discs and packs to reduce in-house fabrication time and scrap

- Packaging that protects edges and surfaces, minimizing handling damage

The result is a favorable ROI: fewer changeovers, cleaner media, and more consistent output quality across critical wire rope manufacturing steps.

Sustainability & Market Trends in manufacturing

Sustainability and process efficiency increasingly guide procurement in metal wire rope manufacturing. Stainless steel twill weave mesh is durable, reusable, and recyclable, aligning with circular economy principles and waste-reduction initiatives on the shop floor. By enabling closed-loop filtration of lubricants and better capture of fines and scale, twill mesh supports cleaner processes and reduced consumable usage. Its longevity and reusability also help lower the environmental footprint compared to disposable media.

Market trends point to higher precision requirements in wire drawing and coating lines, driven by quality benchmarks in construction, offshore, mining, and elevator applications for wire rope. Plants are investing in more advanced filtration and monitoring to protect dies, stabilize surface finish, and improve consistency. Anping County Ansheng Wire Meshes Product Co., Ltd. is aligned with these shifts—offering controlled-aperture twill weave wire mesh, application guidance to hit target differential pressures, and customization that fits modern automated lines. With material options, documentation upon request, and value-added finishing, Ansheng helps manufacturers enhance both performance and sustainability outcomes without complicating supply chains.

Conclusion on twill weave mesh, twill weave wire mesh, twill mesh from Anping County Ansheng Wire Meshes Product Co., Ltd.

From filtration of drawing lubricants to protective screens and extrusion packs, twill weave mesh delivers strength, stability, and precision that wire rope manufacturers depend on. Anping County Ansheng Wire Meshes Product Co., Ltd. combines robust materials, tight tolerances, and practical customization to reduce downtime and elevate product quality. Ready to specify twill mesh for your line? Contact us: email: sales@anshengwiremesh.com. Visit our website: https://www.anshengfilterscreen.com

Post time: Oct . 06, 2025 00:15