stainless welded wire mesh, stainless woven mesh, stainless screen mesh, stainless chicken wire, 1 4 stainless steel mesh is a key solution in the manufacturing industry, specifically within Fabricated metal products and Manufacturing of metal wire mesh. This article explores how Anping County Ansheng Wire Meshes Product Co., Ltd. supports professionals with durable, high-performance products, and explains why this product family is an ideal choice for businesses in these sectors.

Table of Contents

- stainless welded wire mesh, stainless woven mesh, stainless screen mesh, stainless chicken wire, 1 4 stainless steel mesh Overview

- Benefits & Use Cases of stainless welded wire mesh, stainless woven mesh, stainless screen mesh, stainless chicken wire, 1 4 stainless steel mesh in Manufacturing of metal wire mesh

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on stainless welded wire mesh, stainless woven mesh, stainless screen mesh, stainless chicken wire, 1 4 stainless steel mesh from Anping County Ansheng Wire Meshes Product Co., Ltd.

stainless welded wire mesh, stainless woven mesh, stainless screen mesh, stainless chicken wire, 1 4 stainless steel mesh Overview

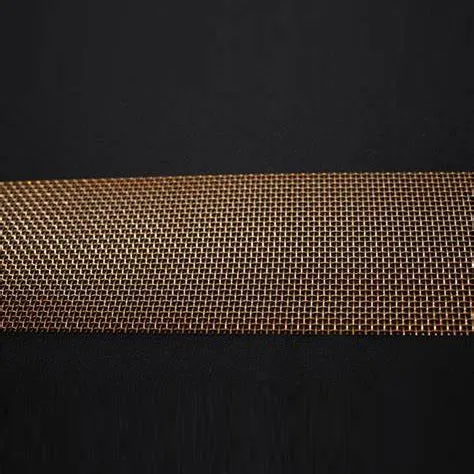

Stainless steel meshes encompass several engineered forms designed for strength, precision, and longevity across production environments. Stainless welded wire mesh is made by resistance-welding intersecting wires into a rigid, dimensionally stable grid ideal for guards, partitions, and structural reinforcement. Stainless woven mesh interlaces warp and weft wires in patterns such as plain, twill, and Dutch weave to deliver precise aperture control for screening and filtration. Stainless screen mesh is a performance category optimized for particle separation and sizing. Stainless chicken wire—typically a hexagonal weave—offers lightweight containment and ventilation with superior corrosion resistance compared with galvanized alternatives. For coarse screening and protective panels, 1 4 stainless steel mesh (1/4-inch opening) balances strength and airflow.

Typical grades include AISI 304 and 316/316L for enhanced corrosion resistance in chloride-rich or hygienic environments. Common specifications reference ISO 9044 and ASTM E2016, with wire diameters ranging from approximately 0.20 mm to 6.00 mm and mesh counts from 2 to 325. Surface finishing options such as pickling and passivation improve cleanliness and durability. Anping County Ansheng Wire Meshes Product Co., Ltd. manufactures to tight tolerances, supplying cut-to-size sheets, rolls, and fabricated assemblies to OEMs and plant operators who require repeatability, flatness, and traceability in demanding applications.

Benefits & Use Cases of stainless welded wire mesh, stainless woven mesh, stainless screen mesh, stainless chicken wire, 1 4 stainless steel mesh in Manufacturing of metal wire mesh

In process industries, stainless woven mesh and stainless screen mesh are integral to filtration, sieving, and grading—whether in food and beverage, pharmaceuticals, petrochemicals, or battery materials. Fine-weave screens maintain tight particle size distribution, while Dutch weaves deliver high-strength filtration with stable differential pressure handling. For plant safety and material flow, stainless welded wire mesh provides robust machine guarding, cage systems, and pallet separation with minimal deflection. The 1 4 stainless steel mesh format is commonly specified for intake screens, HVAC plenums, ventilation guards, and aggregate sizing where airflow and visibility are crucial. For containment and biosecurity around sensitive areas, stainless chicken wire offers corrosion-proof, easy-to-clean barriers.

Key advantages include superior corrosion resistance, stable aperture geometry, high temperature tolerance, and cleanability—critical for GMP and HACCP-regulated facilities. Compared with carbon or galvanized alternatives, stainless meshes reduce contamination risk, repainting, and frequent replacement. Anping County Ansheng Wire Meshes Product Co., Ltd. supports these use cases with application-driven selection (grade, weave pattern, wire diameter), edge finishing, framing and stamping, and rapid prototyping. Their process control and inspection—from wire drawing to weaving/welding to finishing—help ensure consistent mesh count, tensile strength, burr-free edges, and weld integrity, leading to fewer fit-up issues and faster commissioning on site.

Cost, Maintenance & User Experience

Total cost of ownership favors stainless steel in mid-to-long duty cycles. Although the initial purchase price can be higher than carbon steel or galvanized alternatives, stainless welded wire mesh and stainless woven mesh typically extend service life, reduce downtime for repainting or replacement, and maintain hygienic compliance without coatings. In wet, caustic, or chloride environments, 316/316L often outperforms coated substrates by resisting pitting and underfilm corrosion—lowering unplanned maintenance and line stoppages. For coarse applications, 1 4 stainless steel mesh resists deformation, which preserves aperture accuracy and throughput over time.

Maintenance is straightforward: routine rinsing, compatible alkaline detergents, and periodic passivation help keep stainless screen mesh clean and within specification. Customers in fabricated metal products report consistent flatness, tight dimensional tolerances, and reliable weld penetration—attributes that reduce in-field adjustments and scrap. For sanitary processing, stainless chicken wire and woven panels can be steam-cleaned or CIP-washed, aiding compliance. Anping County Ansheng Wire Meshes Product Co., Ltd. packages meshes to minimize transport damage and supplies documentation to support traceability and quality audits, contributing to predictable ROI across multi-year operating horizons.

Sustainability & Market Trends in manufacturing

Stainless steel is recyclable and often produced with significant recycled content, making stainless welded wire mesh and stainless woven mesh a responsible choice for sustainability-minded operations. By eliminating paint systems and reducing replacement frequency, stainless meshes can help lower lifecycle environmental impact. Additionally, precision stainless screen mesh supports higher filtration efficiency and material recovery, which aligns with waste minimization initiatives and stricter emissions and hygiene regulations across food, pharma, and advanced materials.

Market trends point to finer mesh counts for battery powders and cathode/anode processing, demand for higher-strength screens in critical minerals, and hygienic design in food-grade and cleanroom equipment. Architectural and industrial users increasingly specify stainless chicken wire and 1 4 stainless steel mesh for durable, low-maintenance infill panels and guards. Anping County Ansheng Wire Meshes Product Co., Ltd. embraces these trends with application engineering, energy-conscious production practices, and material traceability. Their focus on quality consistency supports customers seeking to meet evolving standards while achieving measurable gains in uptime, product purity, and sustainability metrics.

Conclusion on stainless welded wire mesh, stainless woven mesh, stainless screen mesh, stainless chicken wire, 1 4 stainless steel mesh from Anping County Ansheng Wire Meshes Product Co., Ltd.

From precision screening to durable guards and hygienic barriers, stainless welded wire mesh, stainless woven mesh, stainless screen mesh, stainless chicken wire, and 1 4 stainless steel mesh deliver reliability, cleanability, and long-term value across fabricated metal products and the manufacturing of metal wire mesh. Backed by engineering support, consistent quality, and responsive service, Anping County Ansheng Wire Meshes Product Co., Ltd. is a dependable partner for B2B decision makers seeking performance and lifecycle savings.

Contact us: email: sales@anshengwiremesh.com

Visit our website: https://www.anshengfilterscreen.com

Post time: Oct . 05, 2025 23:05