Brass Wire Mesh: field notes, specs, and what buyers are actually asking

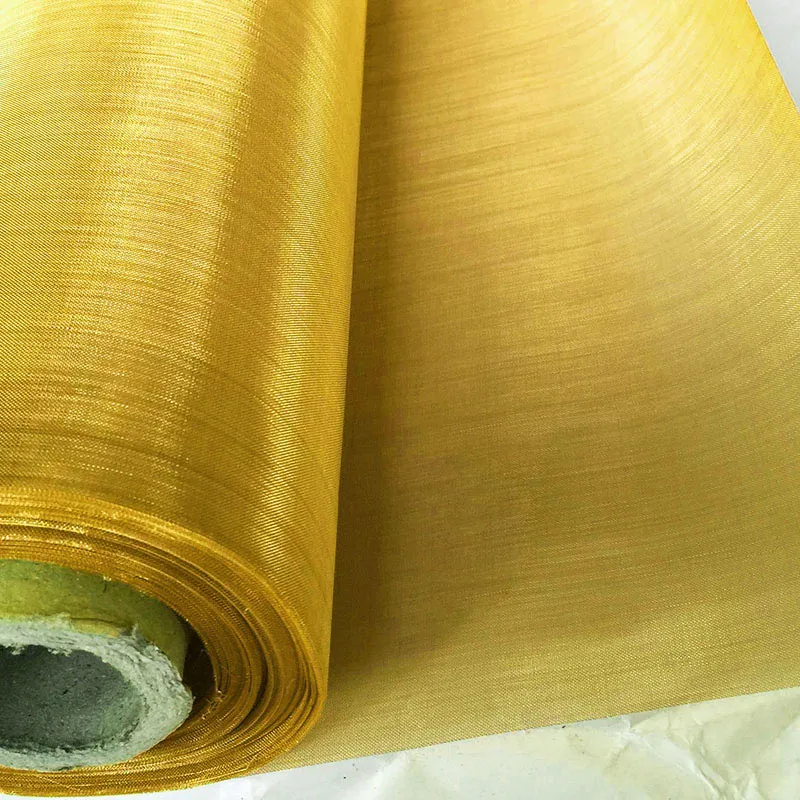

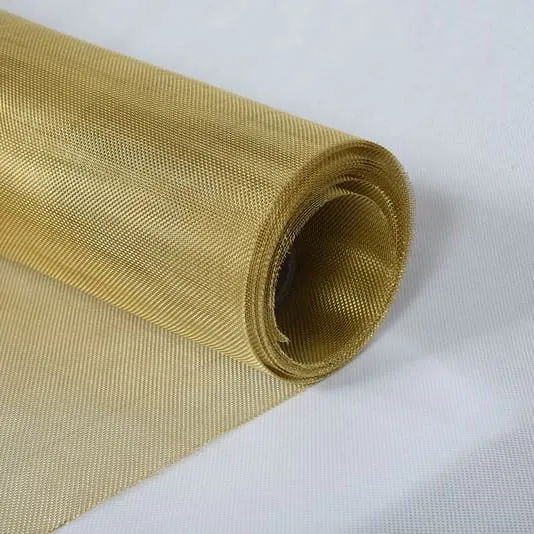

If you work with brass wire mesh, you already know the product lives in that sweet spot between conductivity, formability, and good looks. In the last 18 months, we’ve seen demand tick up in filtration, EMI/RFI shielding, and even boutique architecture. Honestly, it’s a mix of practical engineering and a touch of design flair. Prices did wobble with copper volatility, but not dramatically, and lead times stabilized again in Q2.

Specs that matter (and why they matter)

Brass wire mesh here usually means H65 or H80 alloy (cu-zn), non-magnetic, wear resistant, and nicely ductile for forming small-radius housings or filter inserts. Typical stock: 2–200 mesh, wire dia 0.025–1.0 mm, widths around 0.6–1.5 m, and 30 m rolls. Weaves? Plain for most filters; twill when you want tighter apertures with better stability.

| Parameter | Range / Options | Typical Tolerance | Notes |

|---|---|---|---|

| Mesh count | 2–200 mesh | ≈ ±3% | ASTM E2016 / ISO 9044 guidance |

| Wire diameter | 0.025–1.0 mm | ±0.003–0.01 mm | Depends on temper and mesh |

| Weave | Plain, Twill | — | Plain for flow; twill for finer filtration |

| Alloy | H65, H80 | Chem. per mill cert | Conductive, non-magnetic |

| Width | ≈0.6–1.5 m | ±2–4 mm | Custom widths available |

| Roll length | ≈30 m | ±0.5% | Real-world use may vary |

| Tensile strength | ≈350–600 MPa | Lot-based | Depends on temper & draw |

Process flow and testing (short version)

Materials: H65/H80 brass wire rod → multi-stage drawing → annealing (as required) → weaving (plain/twill) → flattening & tensioning → degreasing → inspection → roll/pack at No.346 Xinying East Street, Anping County, Hebei, China.

- Methods: precision shuttleless looms; calibrated mesh counters; optical aperture checks.

- Testing: mesh count per ASTM E2016; dimensional per ISO 9044; conductivity checks; salt-spray optional (24–96 h) for surface behavior.

- Service life: indoors 5–10 years; light outdoor 2–5 years; marine/saline shorter without coatings.

- Compliance: supplier RoHS/REACH declarations available upon request.

Where engineers use it

- Filtration: fuel pre-filters, plastic extrusion screens, lab sieving.

- EMI/RFI shielding: enclosures and ventilation panels—brass wire mesh balances shield and airflow.

- Architecture: speaker grilles, lamp diffusers, retail fixtures (yes, designers love that warm tone).

- Precision parts: battery tabs, sensor protection, insect screens in chemical plants.

Many customers say they prefer brass wire mesh over stainless for formability and conductivity, even if stainless wins on corrosion in harsher environments.

Vendor snapshot (quick compare)

| Vendor | MOQ | Lead Time | Customization | QC / Certs | Notes |

|---|---|---|---|---|---|

| Ansheng Filter Screen (Anping) | ≈1 roll | 7–15 days | Widths, mesh, cut panels | ISO standards, RoHS/REACH docs | Strong in custom small-batch |

| Importer A (EU) | 5–10 rolls | 2–4 weeks | Limited | CE paperwork, test reports | Convenient local stock |

| Mill B (APAC) | 10+ rolls | 3–6 weeks | OEM scale | Mill certs | Best for volume pricing |

Customization, QA and real-world feedback

Custom widths to 1.5 m, slitting to narrow tapes, cut-to-size panels, and framed screens are common. For brass wire mesh used in EMI vents, ask for measured shielding effectiveness (dB @ frequency) and flatness specs. Customers report fewer handling kinks when rolls ship with edge guards—simple fix, big difference.

Two quick case notes

- Battery lab screens: 120 mesh H65, plain weave; conductivity critical. Result: 2.5% lower contact resistance vs steel screens, per in-house DMM tests.

- Retail lighting grille: 30 mesh twill, antique finish. Result: reduced glare and a warmer visual—designer loved it, installer said it cut cleanly and formed easily.

Bottom line: if you want a balance of filtration precision, conductivity, and workability, brass wire mesh is a solid, versatile choice—just match alloy, weave, and diameter to the job, and verify against ASTM/ISO tolerances.

Authoritative citations

Post time: Oct . 05, 2025 22:35