Introduction

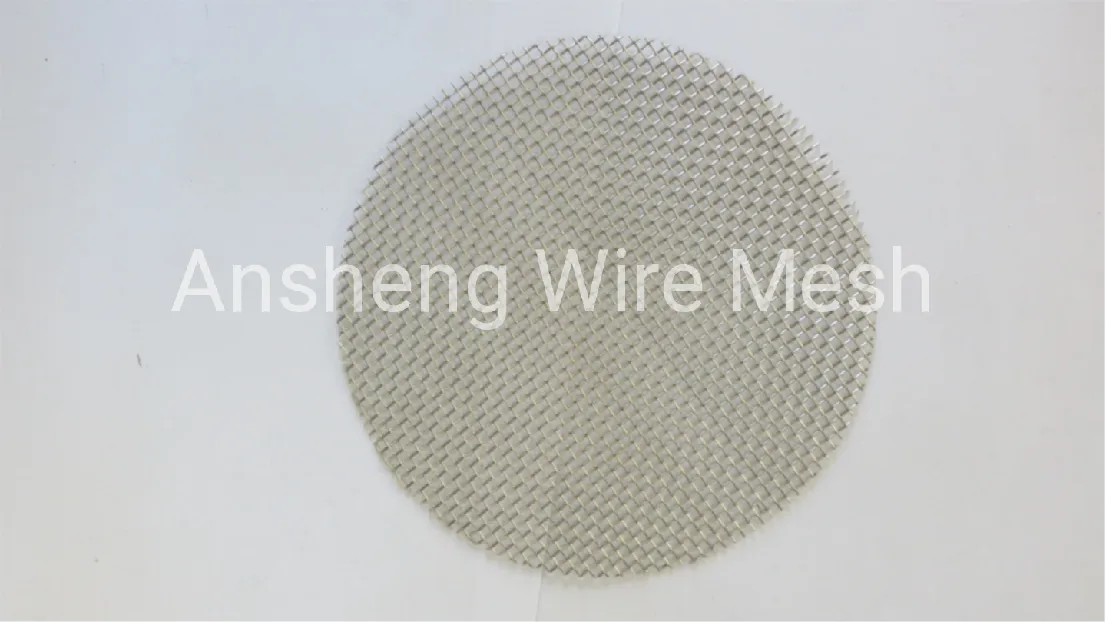

At **Anping County Ansheng Wire Meshes Product Co., Ltd.**, we specialize in manufacturing **wire mesh discs** that combine advanced technology with meticulous craftsmanship. Our **single-layer mesh discs** are engineered to deliver exceptional performance in a wide range of applications, from industrial filtration to precision engineering. This article delves into the **key features**, **technical specifications**, **applications**, and **company background** of our products, ensuring you gain a comprehensive understanding of their value and reliability.

For more information about our **wire mesh discs**, visit our product page.

Product Features and Advantages

Our **single-layer wire mesh discs** are designed to meet the most demanding requirements. Here are the core features that set our products apart:

1. Shape Regularity and Precision

The edges of our mesh discs are meticulously crafted to maintain a regular shape, free from distortion or deformation. This ensures seamless installation and long-term stability during use. The accurate specifications of our mesh discs allow for precise fitting in equipment and systems, minimizing the risk of misalignment or operational inefficiencies.

Learn more about our wire mesh discs.

2. High-Quality Materials

We use premium-grade materials such as **stainless steel 304, stainless steel 201, stainless steel 316, stainless steel 316L, nickel N6, nickel 200, nickel N4, low-carbon steel, and galvanized** options. These materials ensure exceptional corrosion resistance, strength, and toughness, making our mesh discs suitable for harsh environments. The high-quality material selection guarantees longevity and performance under challenging conditions.

Discover our mesh sanding discs.

3. Fine Weaving and Uniformity

Our mesh discs are woven with precision to ensure a consistent mesh size and a defect-free surface. The fine weaving of mesh eliminates issues like skipping or leakage, maintaining filtration accuracy and aesthetic appeal. This level of detail is critical for applications requiring high precision, such as chemical processing or pharmaceutical manufacturing.

Explore our wire mesh discs.

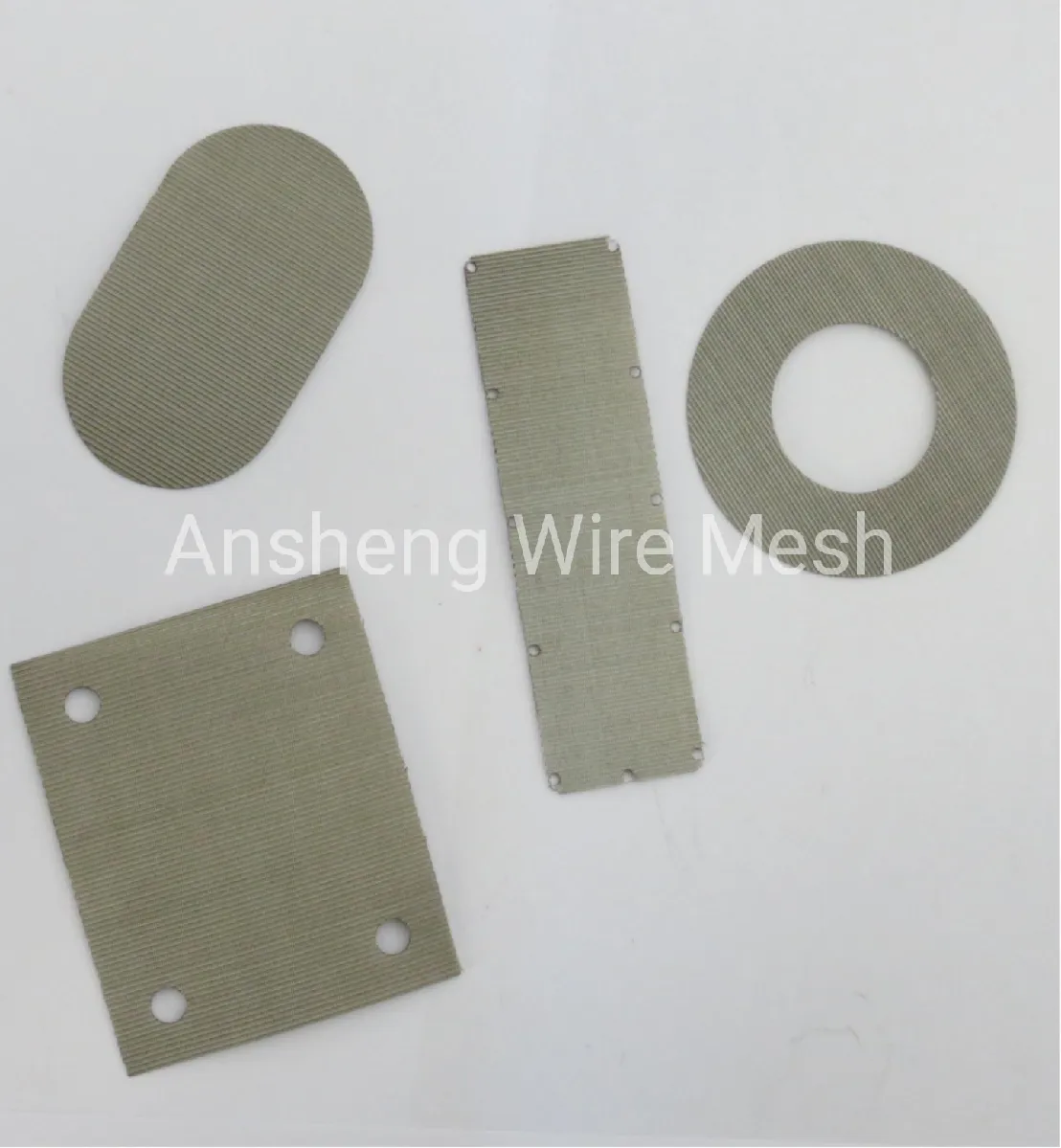

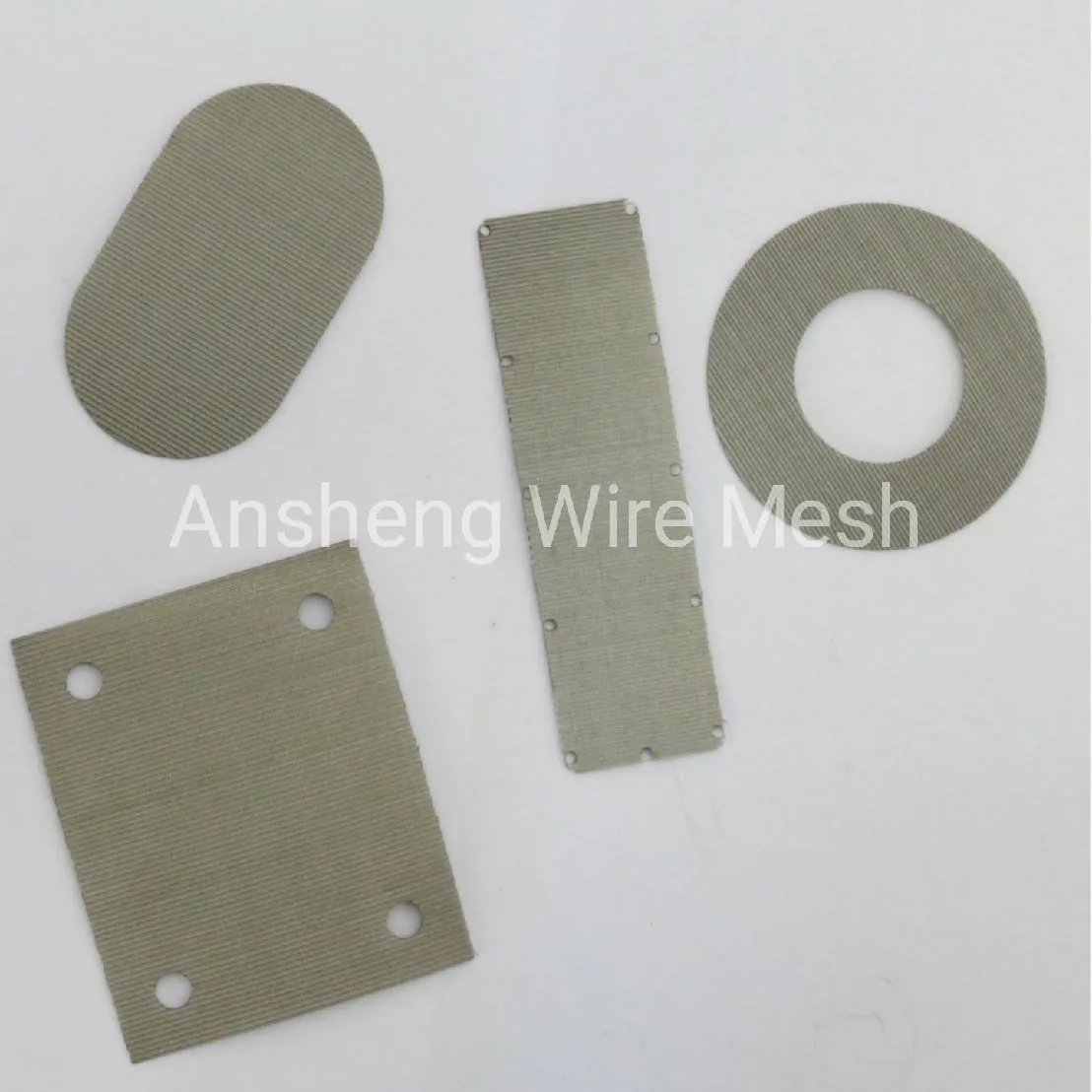

4. Customization and Cost-Efficiency

By leveraging advanced **CNC machining equipment** and a dedicated technical team, we offer tailored solutions to meet specific project requirements. Custom-cutting reduces material waste and lowers costs compared to self-cutting. Our customized mesh ensures optimal resource utilization and minimizes logistics expenses through efficient delivery planning.

Technical Specifications

| Parameter | Details |

|---|---|

| Materials | Stainless steel 304, 201, 316, 316L; Nickel N6, 200, N4; Low-carbon steel; Galvanized |

| Mesh Size Range | 1-635 mesh |

| Dimensions | 1mm-1m (Customizable) |

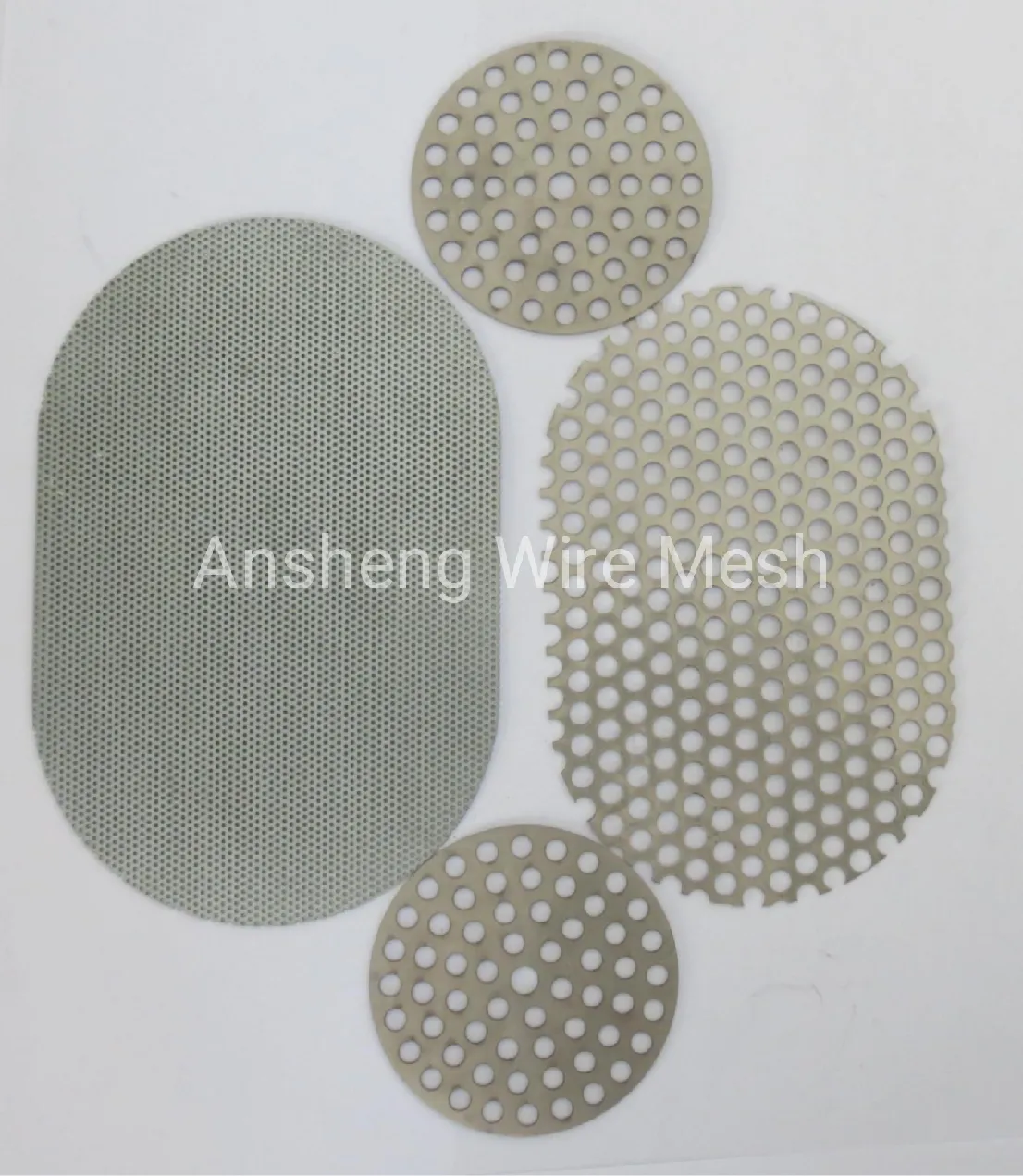

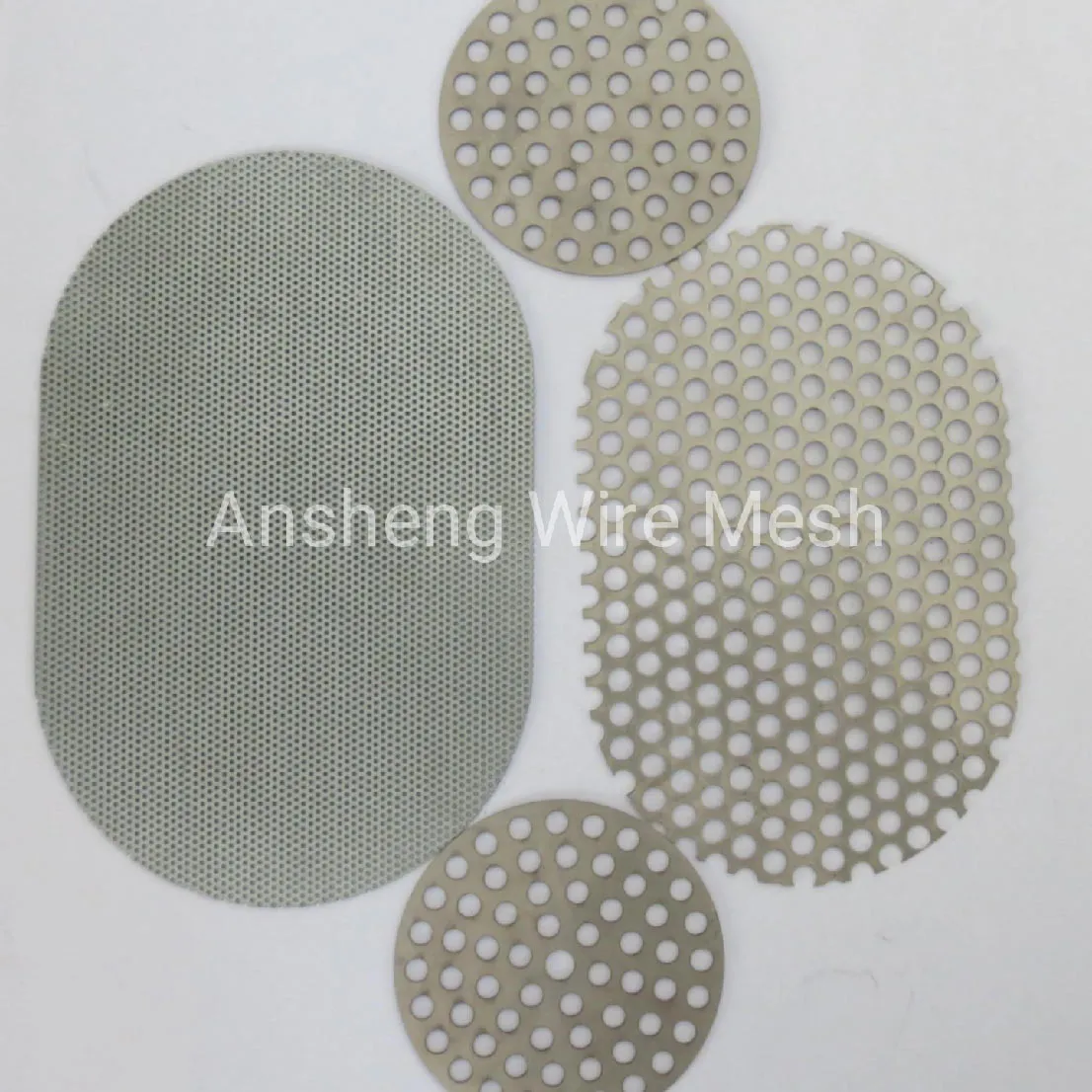

| Shapes | Circular, Square, Oval, Kidney-shaped, Rectangular, Irregular |

| Types | Woven wire mesh, Perforated mesh, Expanded metal mesh |

| Surface Finish | Smooth edges, burr-free, uniform mesh size |

Applications and Industries

Our **single-layer wire mesh discs** are widely used across diverse industries due to their versatility and reliability. Key applications include:

1. Industrial Filtration

Perfect for separating solids from liquids or gases in chemical processing, food and beverage production, and water treatment systems. The accurate specifications of our mesh discs ensure precise filtration, reducing contamination risks.

2. Construction and Manufacturing

Used in concrete sieving, metalworking, and structural components. The high-quality material selection ensures durability in high-stress environments.

3. Automotive and Aerospace

Employed in air and fuel filtration systems, where precision and reliability are critical. The fine weaving of mesh guarantees consistent performance under extreme conditions.

4. Electronics and Semiconductor

Used in dust control and component protection during manufacturing processes. The uniform mesh size prevents particle contamination, safeguarding sensitive equipment.

Company Background

Anping County Ansheng Wire Meshes Product Co., Ltd. is a leading manufacturer of **wire mesh discs** and related products, with a strong commitment to quality and innovation. Based in Anping County, Hebei Province, China, the company leverages advanced production technologies and a skilled workforce to deliver products that meet international standards.

Our customized mesh solutions are designed to address the unique needs of clients, ensuring cost-effectiveness and operational efficiency. By integrating strict production standards and rigorous testing processes, we guarantee that every product meets the highest quality benchmarks.

For more details about our company, visit our official website.

Why Choose Anping County Ansheng Wire Meshes Product Co., Ltd.?

Our products are trusted by industries worldwide for their precision, durability, and cost-efficiency. Here’s why we stand out:

- Advanced Manufacturing: Utilize CNC machining and automated systems for precision and consistency.

- Custom Solutions: Tailored to your specific requirements, reducing waste and saving costs.

- Comprehensive Support: From design to delivery, our team ensures seamless project execution.

- Global Reach: Products are exported to over 50 countries, backed by reliable logistics and customer service.

Industry Standards and Certifications

Our products adhere to international standards for quality and performance. For example, the National Institute of Standards and Technology (NIST) plays a pivotal role in establishing measurement standards that ensure the accuracy and reliability of industrial materials. While our products are not directly referenced in NIST publications, the principles of precision and quality control we uphold align with NIST’s mission to advance technology through rigorous measurement science.

For more information on NIST’s role in standards development, visit the NIST website.

Conclusion

Anping County Ansheng Wire Meshes Product Co., Ltd. offers **single-layer wire mesh discs** that combine cutting-edge technology, premium materials, and precise engineering. Whether you need mesh sanding discs for industrial applications or filter discs for specialized processes, our products are designed to deliver exceptional performance and value. By choosing our solutions, you gain access to a reliable partner committed to innovation, quality, and customer satisfaction.

Explore our full range of products and services at Anping County Ansheng Wire Meshes Product Co., Ltd..

Product Images

References

NIST (National Institute of Standards and Technology). (n.d.). https://www.nist.gov/

Post time: Aug . 03, 2025 06:20