Introduction

In the realm of industrial filtration and precision engineering, single-layer wire mesh discs have emerged as a cornerstone of reliability and performance. These discs, crafted with meticulous attention to detail, are designed to meet the rigorous demands of modern manufacturing, filtration, and material processing. This article delves into the advanced features, technical specifications, and real-world applications of these high-precision components, while also exploring the expertise of their manufacturer, Anping County Ansheng Wire Meshes Product Co., Ltd..

Key Features and Advantages

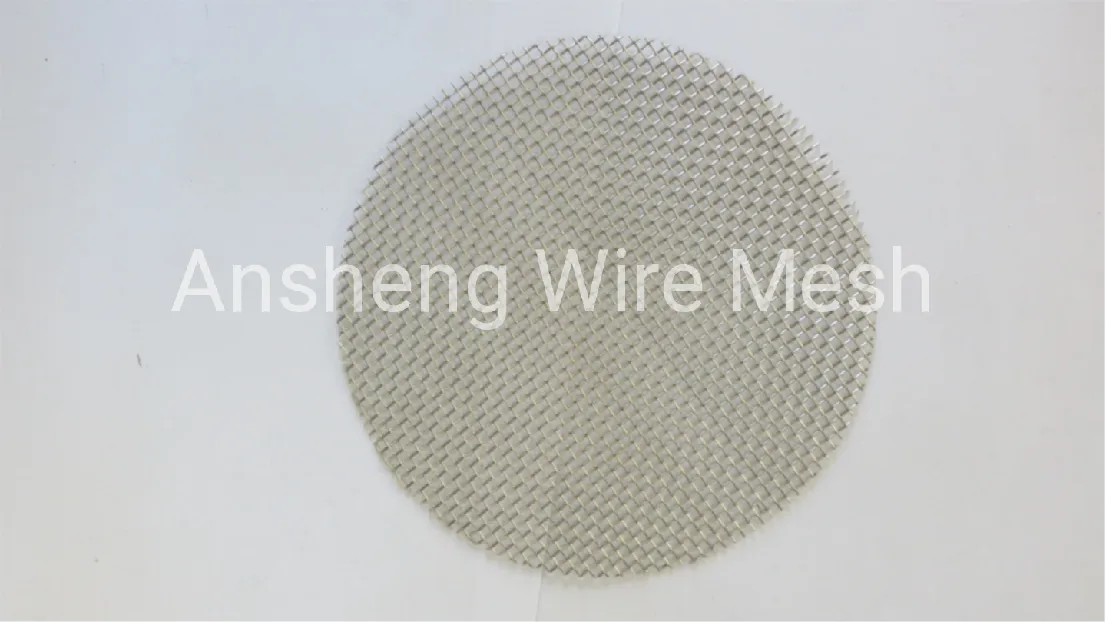

The single-layer wire mesh disc is engineered to deliver exceptional performance across a wide range of applications. Its defining characteristics include:

- Shape Regularity: The edges of the mesh are meticulously crafted to maintain a neat, undistorted form, ensuring seamless installation and long-term stability. This precision minimizes the risk of deformation during use, making it ideal for applications requiring consistent structural integrity.

- High-Quality Materials: The discs are manufactured using premium-grade materials such as stainless steel 304, 201, 316, and 316L, as well as nickel alloys and galvanized steel. These materials provide outstanding corrosion resistance, strength, and toughness, ensuring durability in harsh environments.

- Fine Weaving: The mesh is tightly and evenly woven, with uniform mesh sizes and no defects like skips or leaks. This ensures precise filtration accuracy and a visually appealing finish, critical for applications where aesthetics and functionality are equally important.

- Accurate Specifications: Dimensions such as length, width, and aperture are precisely controlled to meet design requirements. Deviations are kept within allowable ranges, allowing the discs to integrate seamlessly with other equipment or components.

By leveraging advanced CNC machining equipment and a team of experienced engineers, Anping County Ansheng Wire Meshes Product Co., Ltd. ensures that every product adheres to strict quality standards. This commitment to excellence not only saves time and costs for customers but also eliminates the need for rework, making installation more efficient and reliable.

Technical Specifications

| Specification | Details |

|---|---|

| Materials | Stainless steel 304, 201, 316, 316L, nickel N6, nickel 200, nickel N4, low-carbon steel, galvanized steel, and others. |

| Mesh Size Range | 1 to 635 mesh |

| Dimensional Range | 1 mm to 1 m |

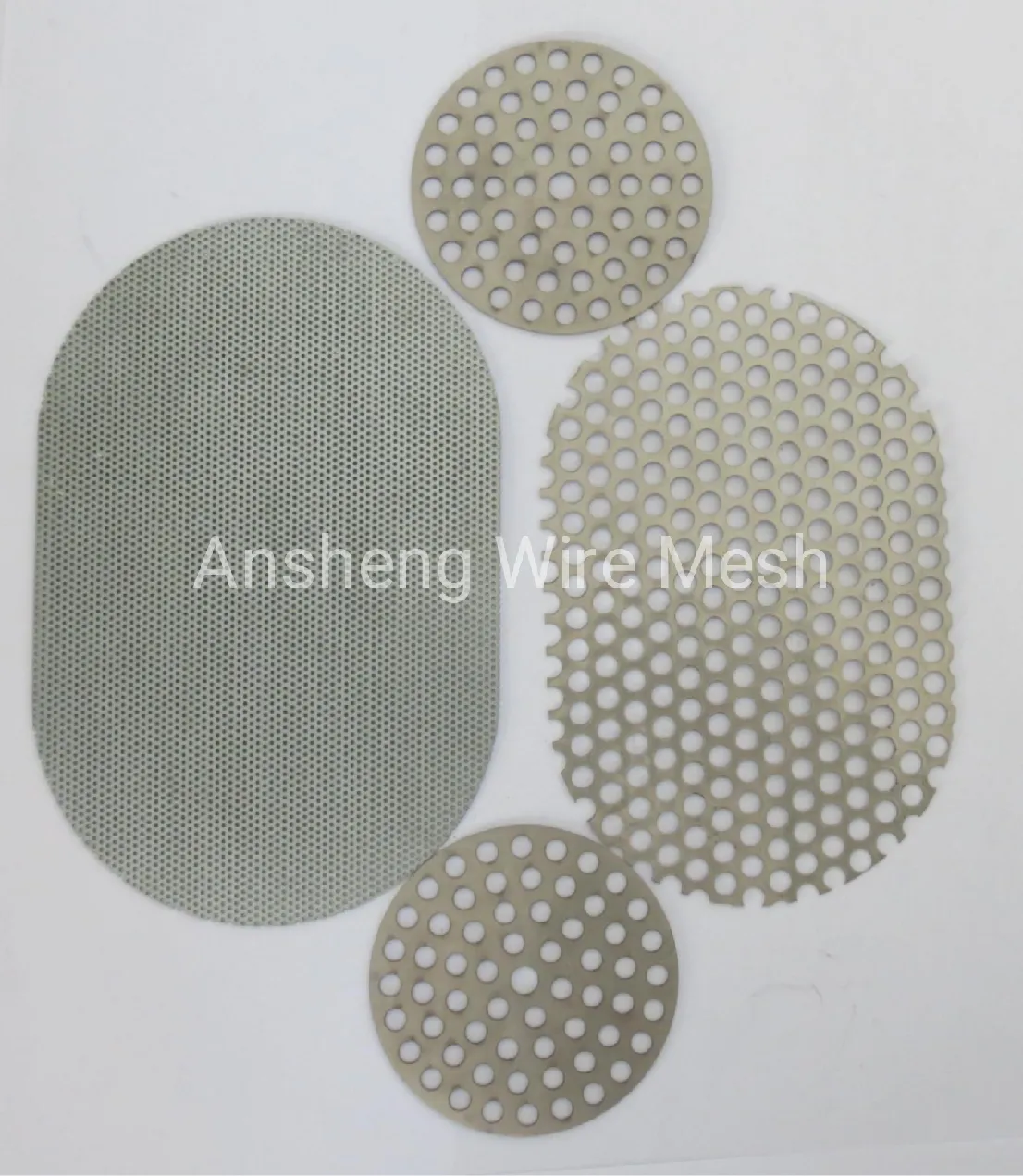

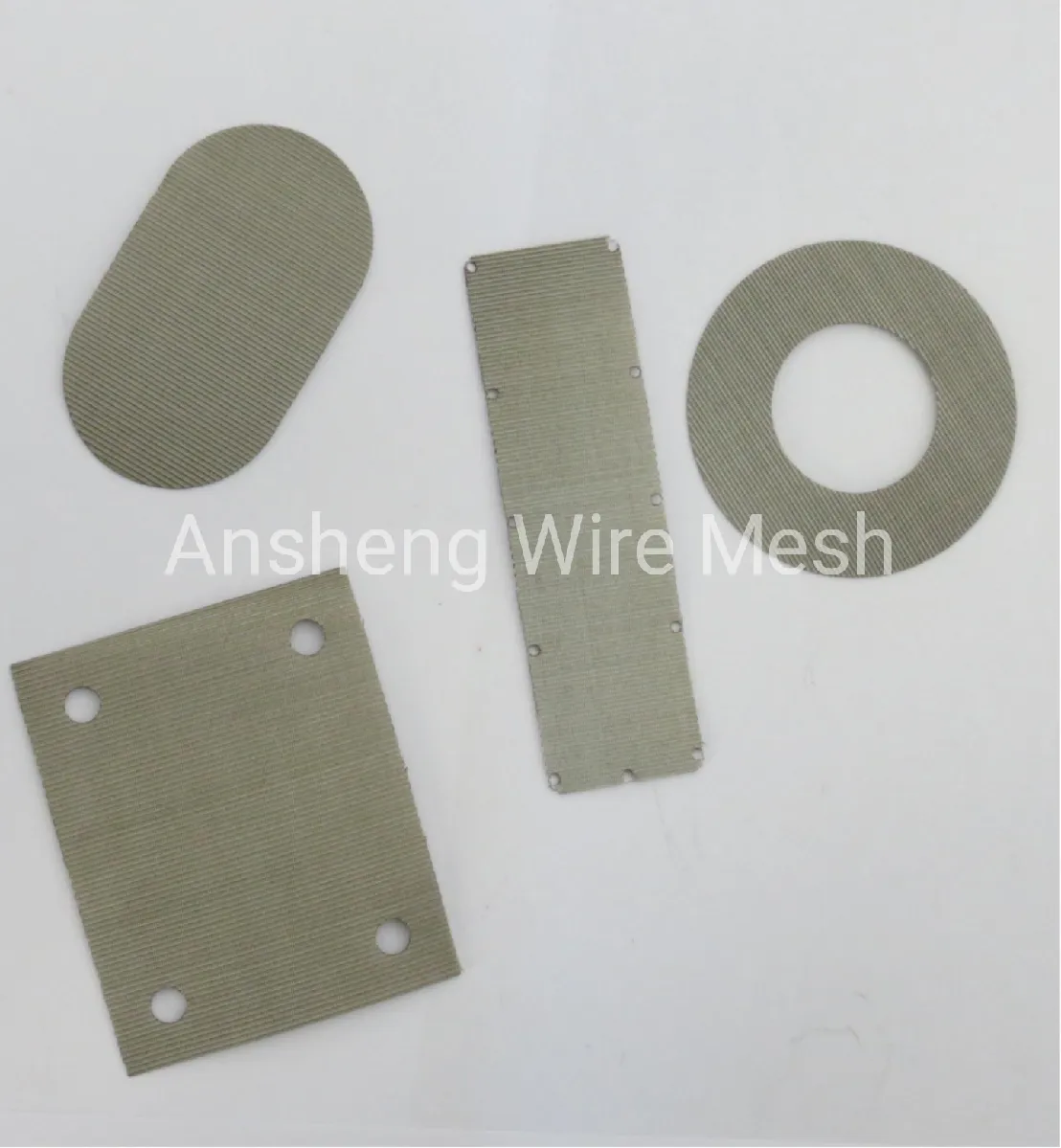

| Shapes | Circle, square, oval, kidney-shaped, rectangle, and irregular shapes. |

| Types | Woven wire mesh, perforated mesh, expanded metal mesh. |

| Surface Finish | Smooth edges, burr-free, and uniform mesh size. |

The versatility of these discs is further enhanced by their ability to be customized to specific requirements. Whether it’s a narrow mesh size for fine filtration or a large diameter for industrial applications, Anping County Ansheng Wire Meshes Product Co., Ltd. offers tailored solutions to meet diverse needs.

Applications in Industry and Beyond

The single-layer wire mesh disc finds applications in a multitude of industries, including:

- Filtration Systems: Used in air, liquid, and gas filtration to remove impurities and ensure product purity. Their precise mesh sizes make them ideal for pharmaceutical, food processing, and chemical industries.

- Material Processing: Employed in sieving, sorting, and separating materials in mining, agriculture, and construction. The durability of the mesh ensures long-term performance even under heavy use.

- Automotive and Aerospace: Integrated into components such as air filters, oil filters, and heat exchangers. The corrosion resistance of stainless steel grades like 316L makes them suitable for harsh environments.

- Electronics and Semiconductor Manufacturing: Utilized in precision cleaning and coating processes, where even the smallest impurities can compromise product quality.

According to the National Institute of Standards and Technology (NIST), "Precision in material specifications is critical for ensuring the reliability and performance of industrial components. Standards such as those developed by NIST provide a framework for manufacturers to achieve consistent quality and interoperability across global supply chains." This aligns with the high-precision manufacturing practices of Anping County Ansheng Wire Meshes Product Co., Ltd., which adheres to strict tolerances and quality control measures.

Why Choose Anping County Ansheng Wire Meshes Product Co., Ltd.?

As a leading manufacturer in the wire mesh industry, Anping County Ansheng Wire Meshes Product Co., Ltd. has built a reputation for innovation, quality, and customer-centric solutions. Here’s what sets them apart:

- Advanced Manufacturing Technology: The company employs state-of-the-art CNC machining equipment and automated production lines to ensure consistency and efficiency. This reduces waste and minimizes the need for manual adjustments, which can introduce errors.

- Customization Capabilities: Unlike bulk purchases of raw materials, which often result in significant waste due to cutting errors, Anping County Ansheng offers precision-cut discs tailored to exact specifications. This not only saves costs but also reduces logistics expenses by optimizing delivery based on actual needs.

- Comprehensive Quality Control: Every product undergoes rigorous testing to ensure compliance with international standards. From material selection to final inspection, the company maintains a stringent quality assurance process.

- Global Reach and Support: With a focus on customer satisfaction, the company provides technical support and after-sales services to ensure seamless integration of their products into existing systems.

By choosing Anping County Ansheng, customers benefit from a partner that prioritizes precision, reliability, and cost-effectiveness. As highlighted in a recent NIST report, "Manufacturers that invest in precision engineering and quality control not only enhance their competitive edge but also contribute to the advancement of global industrial standards."

Conclusion

The single-layer wire mesh disc is a testament to the power of precision engineering and innovative manufacturing. With its exceptional features, versatile applications, and the expertise of Anping County Ansheng Wire Meshes Product Co., Ltd., it has become an indispensable component in modern industry. Whether it’s for filtration, material processing, or specialized engineering applications, these discs deliver performance that meets the highest standards.

As the demand for precision and efficiency continues to grow, the role of high-quality wire mesh discs will only become more critical. By partnering with a trusted manufacturer like Anping County Ansheng, businesses can ensure they are equipped with the tools needed to thrive in an increasingly competitive landscape.

References

National Institute of Standards and Technology (NIST). (n.d.). Driving Innovation. Retrieved from https://www.nist.gov/.

Anping County Ansheng Wire Meshes Product Co., Ltd.. (n.d.). Single Layer Wire Mesh Discs. Retrieved from https://www.anshengfilterscreen.com/single-layer.html.

Post time: Sep . 28, 2025 10:15