At Anping County Ansheng Wire Meshes Product Co., Ltd., we specialize in delivering high-precision wire mesh discs that meet the exacting demands of modern industrial applications. Our Single Layer Wire Mesh Discs are engineered to combine durability, accuracy, and versatility, making them an essential component in filtration, sieving, and industrial separation processes. This article explores the advanced features, technical specifications, and real-world applications of our products, while highlighting the company's commitment to quality and innovation.

Product Overview

Our Single Layer Wire Mesh Discs are designed to provide exceptional performance in a wide range of industrial environments. Whether used in mesh sanding discs or as filter discs, these products are crafted to meet the highest standards of precision and reliability. The manufacturing process involves advanced CNC machining, expert craftsmanship, and rigorous quality control to ensure every disc meets the required specifications.

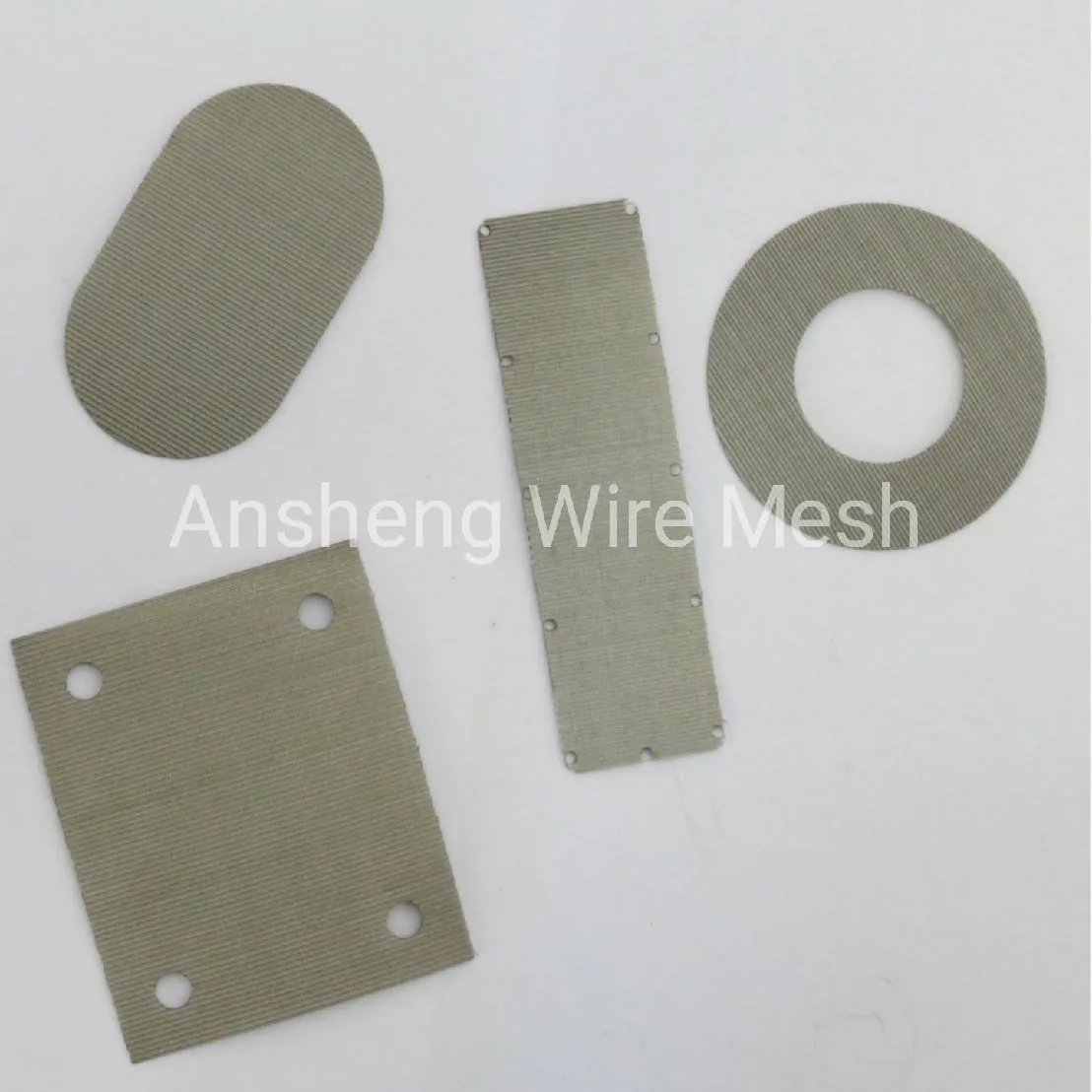

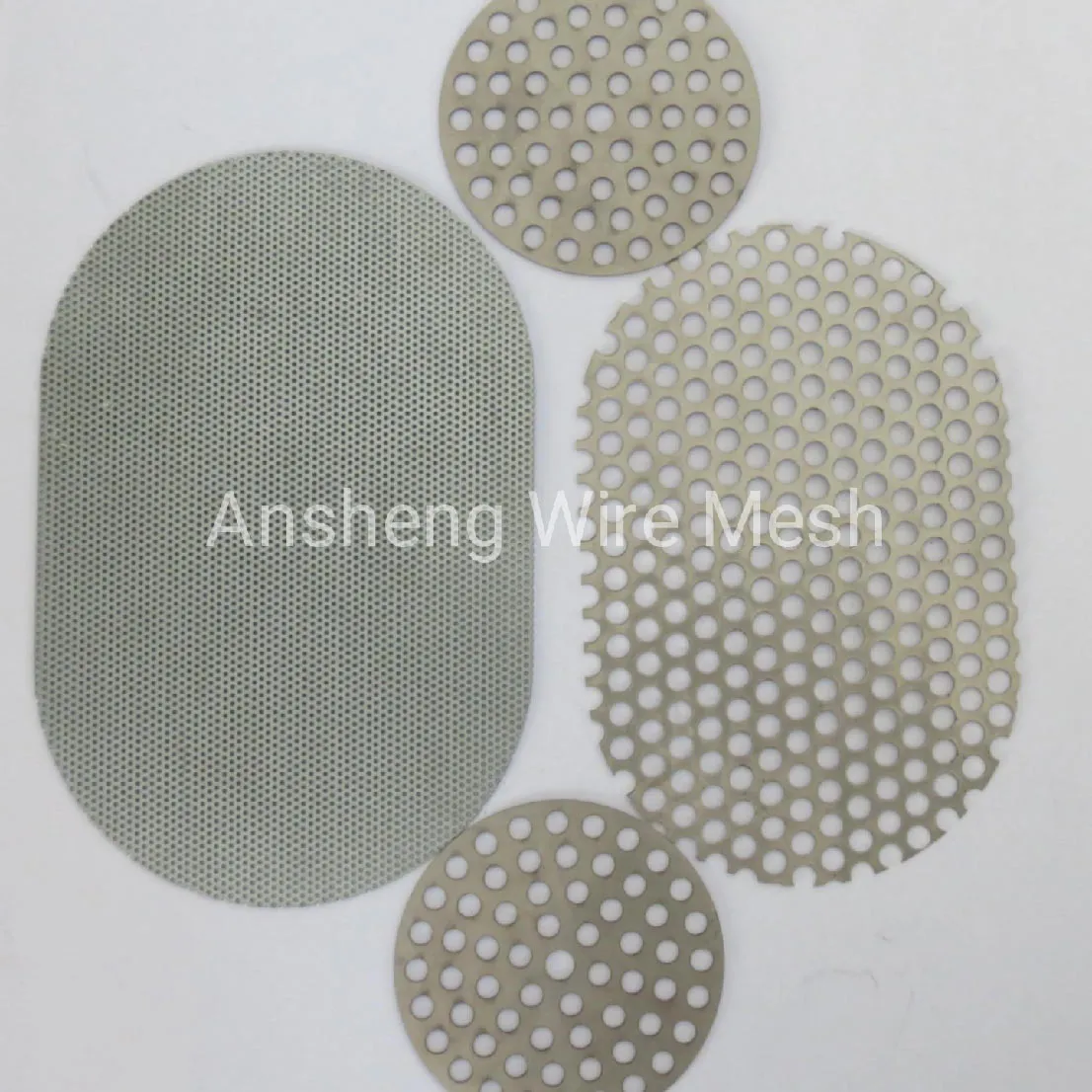

Product showcase of the Single Layer Wire Mesh Discs

Key Features and Advantages

1. Shape Regularity and Structural Integrity

One of the standout features of our wire mesh discs is their shape regularity. The edges are meticulously crafted to be neat, free from distortion or deformation, ensuring a consistent and stable structure. This design not only simplifies installation but also enhances the disc's performance during operation. The regular shape allows for seamless integration with other equipment, reducing the risk of misalignment or instability.

2. High-Quality Materials for Enhanced Durability

We use high-purity raw materials such as stainless steel 304, stainless steel 201, stainless steel 316, stainless steel 316L, nickel N6, nickel200, nickel N4, low-carbon steel, and galvanized materials. These materials are selected for their corrosion resistance, strength, and toughness, ensuring the discs can withstand harsh industrial environments. The use of premium materials also extends the product's lifespan, reducing the need for frequent replacements.

High-quality materials ensure durability and performance

3. Fine Weaving for Precision Filtration

The fine weaving of our mesh discs ensures a tightly and evenly woven structure with consistent mesh sizes. This precision minimizes defects such as skipping or leaking, guaranteeing filtration accuracy and overall aesthetics. Whether used in mesh sanding discs or filter discs, the uniform mesh size ensures reliable performance in critical applications.

4. Accurate Specifications for Seamless Integration

Our Single Layer Wire Mesh Discs are manufactured to meet precise dimensional requirements. The length, width, and aperture are controlled within allowable tolerances, ensuring accurate installation in predefined positions. This level of precision allows the discs to work harmoniously with other components, reducing the risk of operational inefficiencies or equipment damage.

Precision engineering ensures accurate specifications

Technical Specifications

| Parameter | Details |

|---|---|

| Materials | Stainless steel 304, stainless steel 201, stainless steel 316, stainless steel 316L, nickel N6, nickel200, nickel N4, low-carbon steel, galvanized |

| Mesh Size Range | 1-635 mesh |

| Dimension Range | 1mm-1m |

| Shapes | Circle, Square, Oval, Kidney-shaped, Rectangle, Irregular shape |

| Types | Woven wire mesh, perforated mesh, expanded metal mesh |

| Surface Finish | Smooth edges, burr-free |

Applications in Industrial and Commercial Sectors

The versatility of our wire mesh discs makes them suitable for a wide range of applications. Some of the key use cases include:

- Filtration Systems: Used in filter discs to separate particles from liquids or gases, ensuring clean and efficient operation.

- Industrial Sieving: Ideal for sorting and grading materials in industries such as food processing, pharmaceuticals, and mining.

- Surface Preparation: Employed in mesh sanding discs for surface finishing and polishing tasks.

- Architectural and Decorative Uses: The aesthetic appeal of the discs makes them suitable for design applications where both functionality and visual appeal are important.

Company Background: Anping County Ansheng Wire Meshes Product Co., Ltd.

Anping County Ansheng Wire Meshes Product Co., Ltd. is a leading manufacturer of wire mesh discs and related products, with a reputation for excellence in quality and innovation. Located in Anping County, Hebei Province, China, the company has been serving the global market for over a decade, providing customized solutions to meet the unique needs of its clients.

Our commitment to precision engineering is reflected in our advanced CNC machining equipment and experienced technical team. We adhere to strict production standards and testing protocols to ensure that every product meets the highest quality benchmarks. By focusing on customization and cost-efficiency, we help clients reduce material waste, lower transportation costs, and streamline their operations.

As highlighted by the National Institute of Standards and Technology (NIST), "Precision and accuracy are critical in industrial applications, as they directly impact the reliability and performance of equipment and processes." This principle aligns with our approach to manufacturing, where every wire mesh disc is crafted to meet exacting standards.

Why Choose Our Customized Solutions?

While purchasing raw mesh rolls and cutting them in-house may seem cost-effective, it often leads to significant material waste and increased costs. Our customized wire mesh discs are precision-cut in-house, eliminating waste and ensuring optimal use of materials. Additionally, our logistics planning helps reduce shipping costs, making our solutions more economical and environmentally friendly.

By partnering with Anping County Ansheng Wire Meshes Product Co., Ltd., you gain access to a reliable supplier that prioritizes quality, efficiency, and customer satisfaction. Our products are designed to enhance productivity, reduce downtime, and deliver long-term value.

Conclusion

The Single Layer Wire Mesh Discs from Anping County Ansheng Wire Meshes Product Co., Ltd. represent the pinnacle of precision engineering and industrial innovation. With their accurate specifications, high-quality materials, and versatile applications, these discs are an indispensable asset for industries that demand reliability and performance. Whether you're involved in filtration, sieving, or surface preparation, our products are designed to meet your needs with unmatched quality and efficiency.

For more information about our wire mesh discs and Anping County Ansheng Wire Meshes Product Co., Ltd., visit our official website or contact our team of experts today.

References

National Institute of Standards and Technology (NIST). (n.d.). Driving Innovation. Retrieved from https://www.nist.gov.

Post time: Jul . 29, 2025 20:20