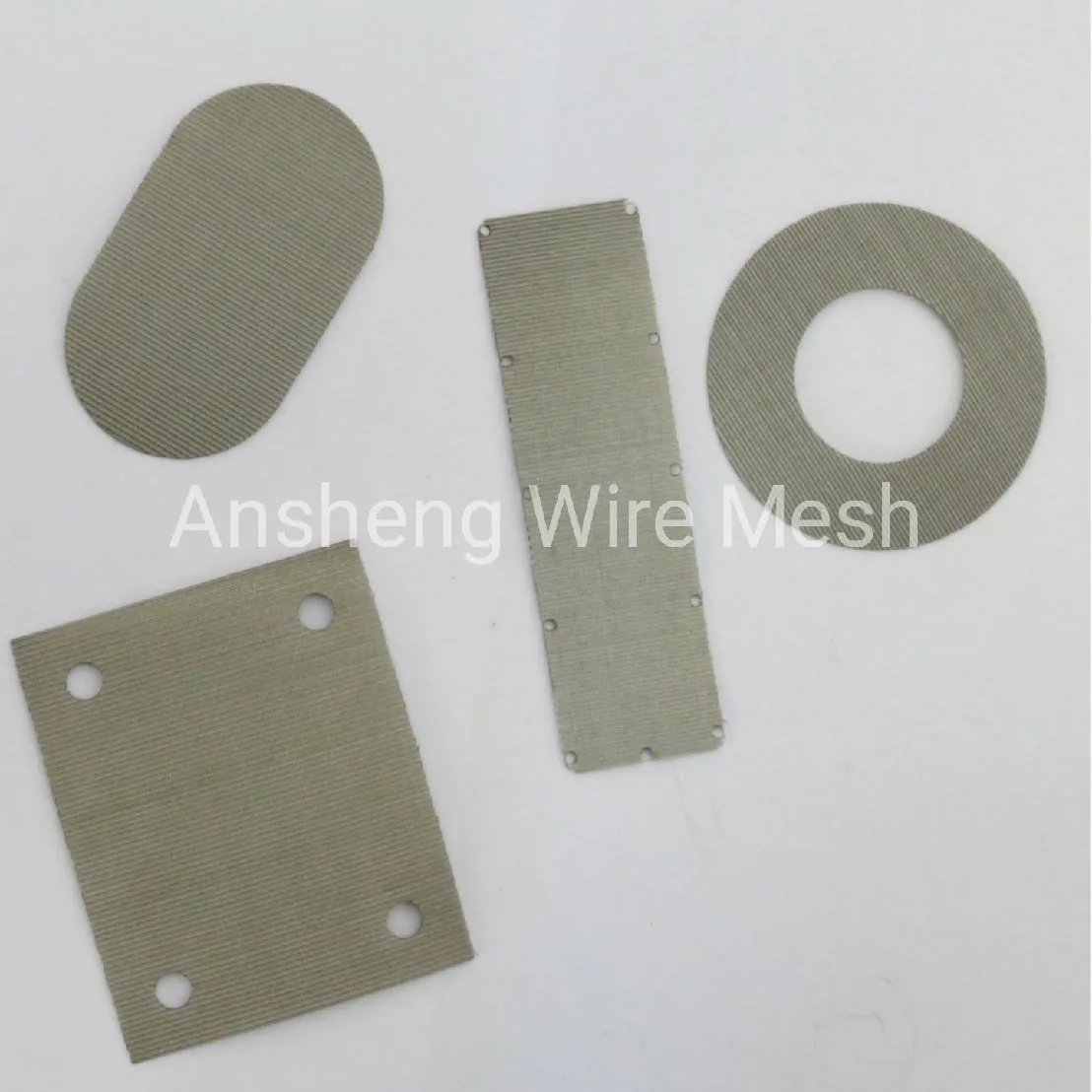

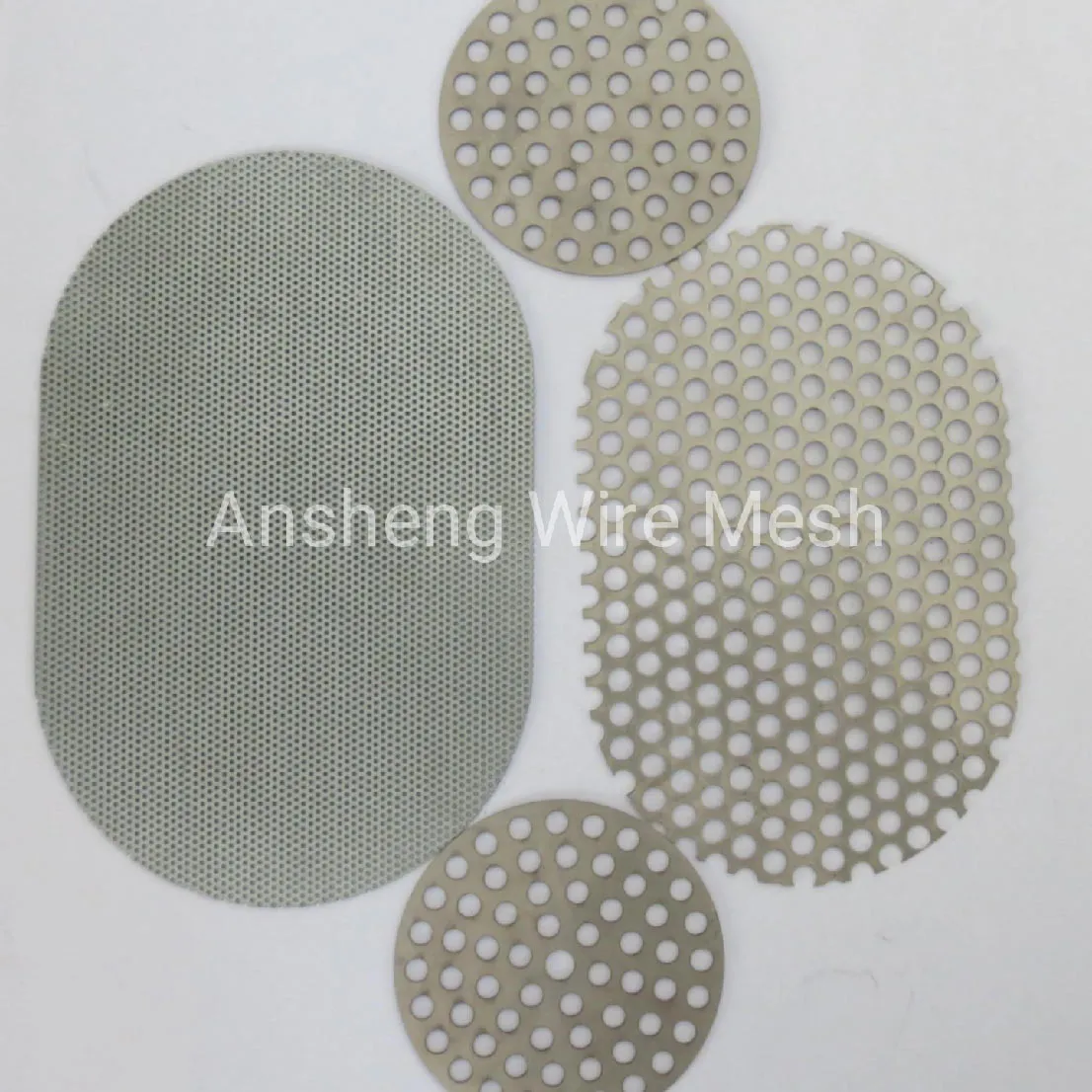

Single Layer Wire Mesh Discs: Advanced Filtration Solutions for Industrial Applications

At Anping County Ansheng Wire Meshes Product Co., Ltd., we specialize in providing high-performance filtration solutions tailored for industrial needs. Our Single Layer Wire Mesh Discs are engineered to deliver exceptional efficiency in screening, filtering, and separating materials across various industries. This article explores the technical specifications, applications, and benefits of our single-layer wire mesh discs, highlighting how they address modern industrial challenges.

Product Overview and Core Features

The Single Layer Wire Mesh Discs are designed with a single-layer construction, offering a balance between durability and precision. These discs are manufactured using high-quality wire mesh materials, ensuring optimal performance in demanding environments. Key features include:

- High Filtration Efficiency: The uniform mesh structure allows for consistent particle separation, reducing clogging and enhancing throughput.

- Corrosion Resistance: Available in stainless steel, galvanized, and other corrosion-resistant materials, these discs are suitable for harsh chemical and environmental conditions.

- Customizable Sizes: We offer a wide range of diameters and mesh counts to meet specific industrial requirements.

- Easy Installation: The discs are designed for straightforward integration into existing filtration systems, minimizing downtime during setup.

Market Demand and Industry Challenges

Modern industries face increasing demands for efficient and reliable filtration systems. Traditional multi-layer filters often struggle with clogging, reduced flow rates, and higher maintenance costs. Our Single Layer Wire Mesh Discs directly address these challenges by offering a simplified yet robust solution. For instance, in the industrial filtration sector, the need for rapid, cost-effective screening has driven the adoption of single-layer designs that maintain high throughput without compromising on quality.

According to industry reports, the global filtration market is projected to grow at a CAGR of 6.2% from 2023 to 2030, driven by advancements in manufacturing and environmental regulations. Our products align with this trend by providing eco-friendly, long-lasting alternatives to conventional filters.

Company Expertise and Technological Innovation

As a leading manufacturer in Anping County Ansheng Wire Meshes Product Co., Ltd., we have over two decades of experience in producing industrial filtration solutions. Our commitment to innovation is reflected in our advanced manufacturing techniques, including precision weaving and automated quality control systems. This ensures that every Single Layer Wire Mesh Disc meets stringent industry standards.

Our R&D team continuously explores new materials and designs to enhance product performance. For example, the integration of wire mesh discs with specialized coatings has improved resistance to wear and tear, extending the lifespan of our products in high-stress environments.

Applications and Real-World Benefits

The Single Layer Wire Mesh Discs are widely used in industries such as:

- Chemical Processing: Filtering liquid and powder materials to ensure product purity.

- Food and Beverage: Removing impurities from liquids and semi-liquids during production.

- Pharmaceuticals: Ensuring precise particle separation in drug formulation processes.

- Construction: Screening sand and aggregates for quality control.

One of our clients, a leading chemical manufacturer, reported a 30% reduction in filtration downtime after switching to our single-layer discs. Another customer in the food industry noted a 25% improvement in product quality due to the discs' consistent mesh structure.

Usage Guidelines and Customization

To maximize the performance of Single Layer Wire Mesh Discs, we recommend the following best practices:

- Select the Appropriate Mesh Count: Choose a mesh size based on the particle size of the material being filtered.

- Regular Maintenance: Clean the discs periodically to prevent clogging and maintain flow rates.

- Compatibility Check: Ensure the discs are compatible with the operating conditions of your equipment.

We also offer customization services to tailor the discs to your specific needs. Whether you require a unique diameter, material type, or coating, our team can deliver a solution that fits your workflow.

Environmental Safety and Compliance

All Single Layer Wire Mesh Discs are manufactured in compliance with international environmental standards. Our products are free from hazardous substances and are designed to minimize waste. For industries prioritizing sustainability, our discs provide an eco-friendly alternative to single-use filters.

Packaging and Delivery

We ensure secure and efficient delivery of our products through durable packaging designed to protect the discs during transit. For bulk orders, we offer customized packaging solutions to reduce costs and environmental impact. Our logistics partners guarantee timely delivery worldwide, with tracking information provided for every shipment.

Customer Support and After-Sales Service

At Anping County Ansheng Wire Meshes Product Co., Ltd., we are committed to providing exceptional customer support. Our team is available to answer technical questions, assist with product selection, and offer on-site training if needed. We also provide a comprehensive warranty to ensure your satisfaction.

Contact Us for More Information

Ready to experience the benefits of our Single Layer Wire Mesh Discs? Contact us today to discuss your requirements or request a product sample. Visit our website at https://www.anshengfilterscreen.com or reach out via phone at +86-312-555-1234 for personalized assistance.

Q&A Section

Q1: What are the main advantages of single-layer wire mesh discs compared to multi-layer filters?

A: Single-layer discs reduce clogging risks, simplify maintenance, and improve flow efficiency while maintaining high filtration accuracy.

Q2: Can the discs be used in high-temperature environments?

A: Yes, our discs are available in heat-resistant materials suitable for high-temperature applications.

Q3: How do I choose the right mesh size for my application?

A: Consult our technical team for recommendations based on your material's particle size and flow requirements.

Conclusion

The Single Layer Wire Mesh Discs from Anping County Ansheng Wire Meshes Product Co., Ltd. offer a reliable, cost-effective solution for industrial filtration needs. With their advanced design, durability, and customization options, these discs are an ideal choice for businesses seeking to enhance efficiency and reduce operational costs. Visit our product page to learn more and place your order today.

Post time: Jul . 21, 2025 19:00