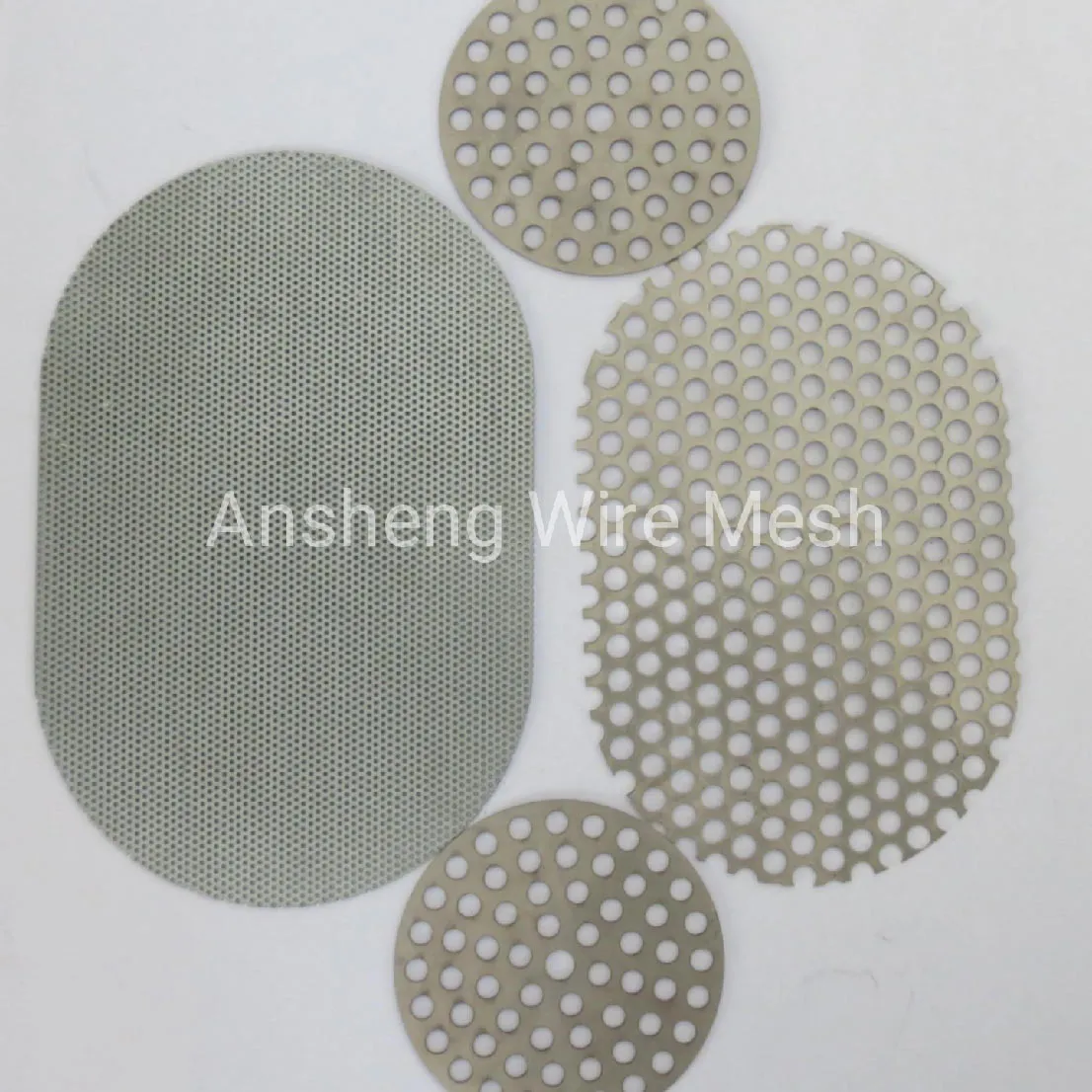

Wire mesh discs are essential components in a wide range of industrial and commercial applications, offering a combination of durability, precision, and adaptability. Whether used for filtration, screening, or structural support, these discs are engineered to meet exacting standards. This article explores the Single Layer Wire Mesh Discs produced by Anping County Ansheng Wire Meshes Product Co., Ltd., highlighting their advanced manufacturing processes, technical specifications, and real-world applications. Additionally, we reference authoritative standards from the National Institute of Standards and Technology (NIST) to underscore the importance of precision in industrial components.

Advanced Manufacturing and Material Quality

The Single Layer Wire Mesh Discs are crafted using high-purity raw materials, including stainless steel grades such as 304, 201, 316, and 316L, as well as nickel alloys and galvanized steel. These materials are selected for their corrosion resistance, strength, and longevity, ensuring the discs can withstand demanding environments. According to the NIST, material quality is a critical factor in the performance of industrial components, as even minor deviations can lead to failure under stress or over time.

The manufacturing process leverages advanced CNC machining equipment and a team of experienced technicians. This ensures that each disc adheres to strict tolerances, with deviations controlled within acceptable ranges. The result is a product that maintains dimensional accuracy, a key requirement for seamless integration with other machinery or systems.

Key Features and Benefits

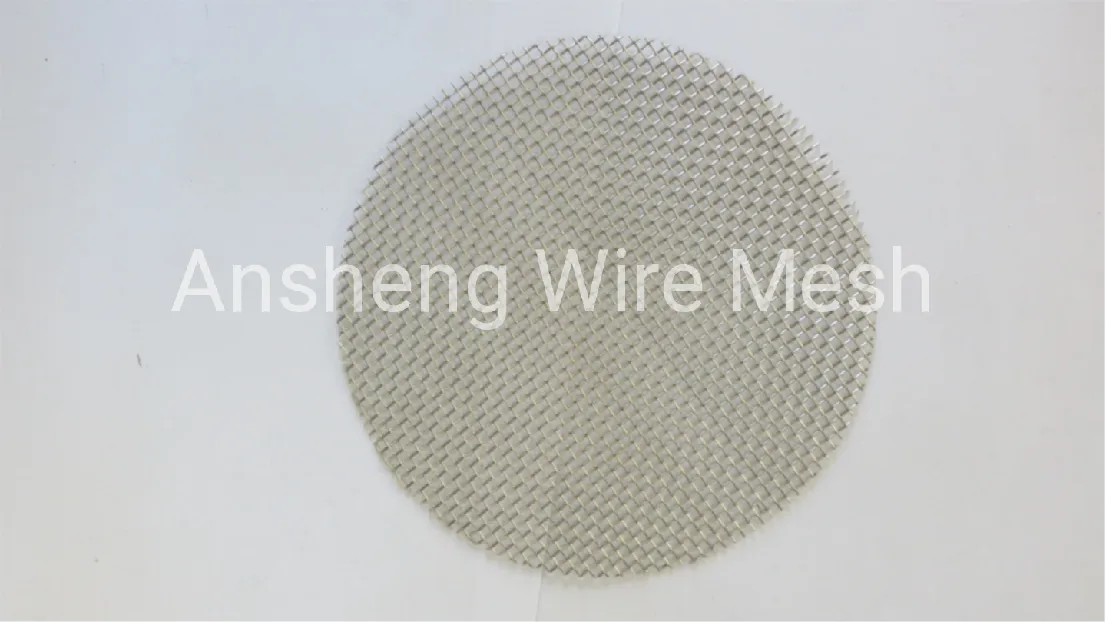

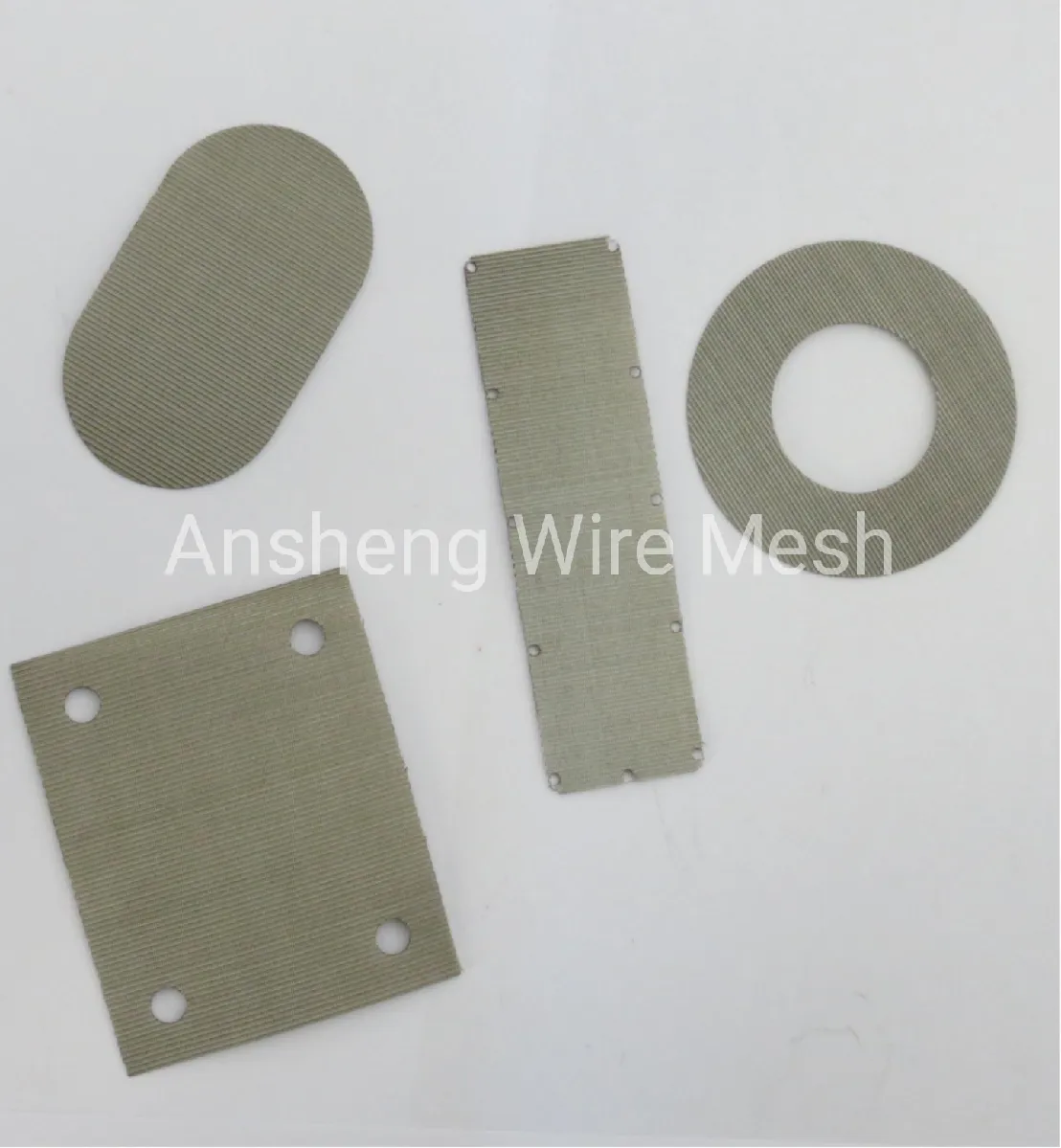

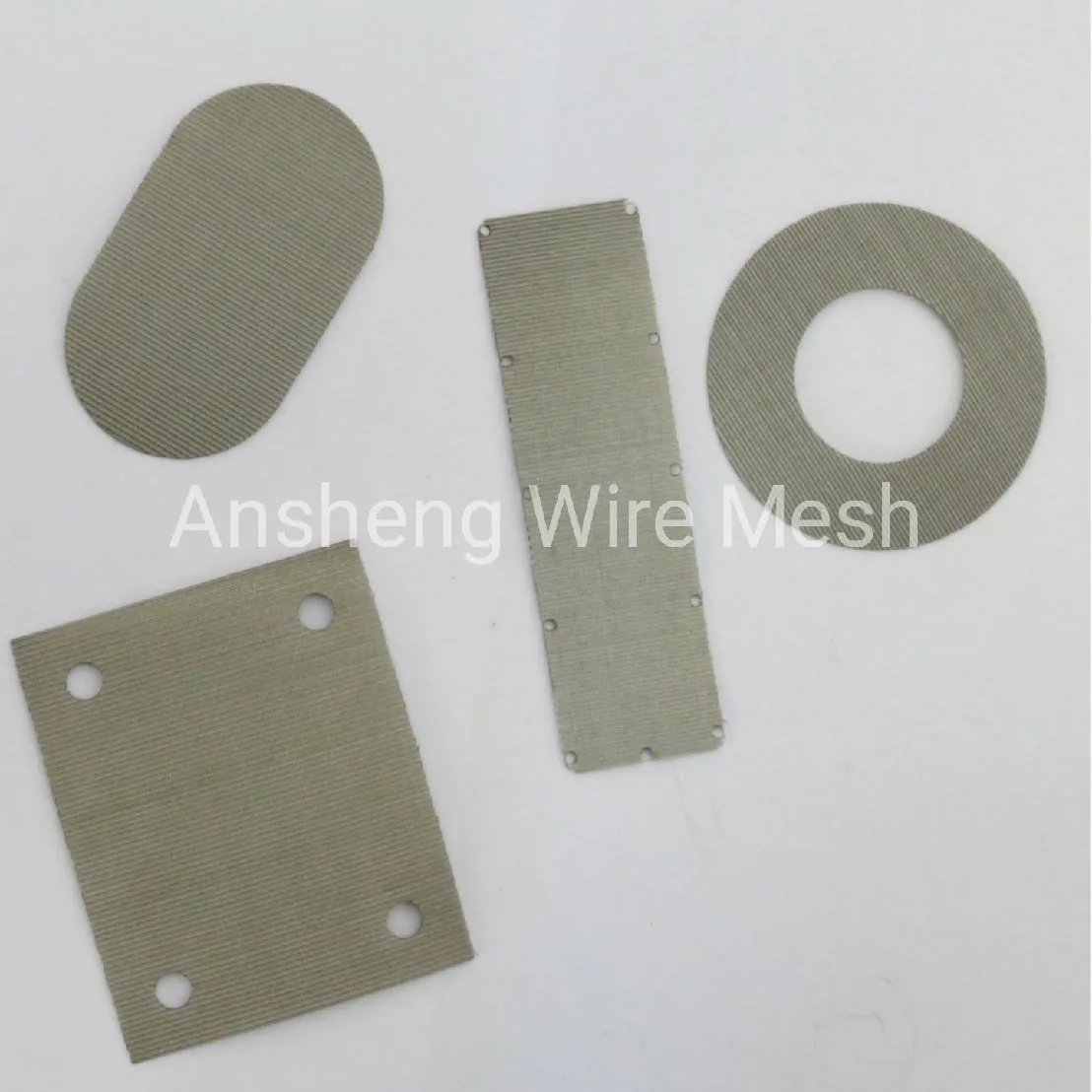

One of the standout features of these wire mesh discs is their shape regularity. The edges are meticulously finished to prevent distortion or deformation, ensuring a clean, uniform appearance. This not only enhances aesthetic appeal but also simplifies installation and reduces the risk of misalignment during use.

The fine weaving of the mesh ensures consistent mesh sizes and eliminates defects such as skipped threads or gaps. This precision is vital for applications requiring high filtration accuracy, such as in the pharmaceutical or food processing industries. NIST emphasizes that precise mesh sizes are essential for maintaining product quality and compliance with industry standards.

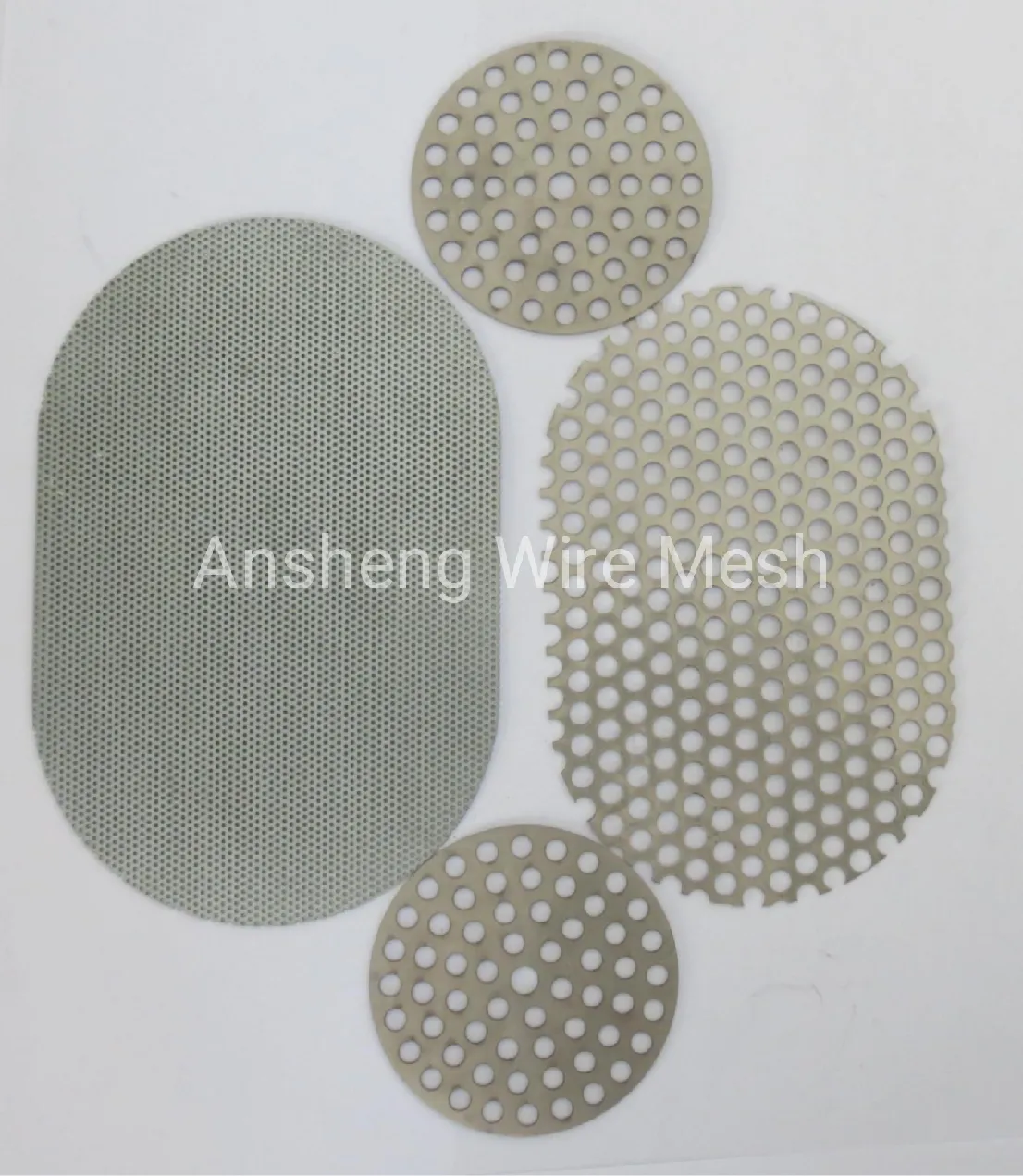

Customization is another major advantage. Unlike pre-cut rolls that may lead to material waste and higher costs, the company specializes in cutting discs to exact specifications. This approach minimizes material loss and reduces logistics expenses, as the discs are delivered directly to the customer’s needs. As noted by NIST, optimizing production and transportation processes can significantly lower costs while maintaining quality.

Technical Specifications

| Category | Details |

|---|---|

| Materials | Stainless Steel 304, 316, 316L; Nickel N6, Nickel 200; Low-Carbon Steel; Galvanized Steel |

| Mesh Sizes | 1 to 635 mesh |

| Dimensions | 1mm to 1m |

| Shapes | Circular, Square, Oval, Kidney-Shaped, Rectangular, Irregular |

| Types | Weave Wire Mesh, Perforated Mesh, Expanded Metal Mesh |

| Surface Finish | Smooth, Burr-Free Edges |

Applications Across Industries

The versatility of Single Layer Wire Mesh Discs makes them suitable for diverse applications. In the NIST-recognized field of precision engineering, these discs are used in filtration systems, where their uniform mesh size ensures effective separation of particles. For example, in the food and beverage industry, they help maintain product purity by filtering out contaminants.

In the automotive sector, the discs are employed in air and oil filtration systems, where their durability and resistance to corrosion are critical. Additionally, their ability to be customized for specific shapes and sizes makes them ideal for specialized machinery, such as in the manufacturing of electronic components or medical devices.

The mesh sanding discs variant is particularly useful in surface preparation tasks, where a consistent texture is required. This application aligns with NIST’s focus on precision in manufacturing, as even minor irregularities can affect the performance of finished products.

Company Background and Commitment to Quality

Anping County Ansheng Wire Meshes Product Co., Ltd. has established itself as a leader in the production of wire mesh solutions. With decades of experience, the company combines traditional craftsmanship with modern technology to deliver products that meet global standards. Their commitment to quality is evident in their rigorous testing processes and adherence to international specifications.

As highlighted by NIST, the importance of standardized manufacturing cannot be overstated. Anping County Ansheng’s focus on precise dimensions and material integrity ensures their products are compatible with a wide range of industrial systems, reducing the need for costly modifications or replacements.

Conclusion

The Single Layer Wire Mesh Discs from Anping County Ansheng Wire Meshes Product Co., Ltd. exemplify the perfect blend of innovation, quality, and customization. By leveraging advanced manufacturing techniques and high-quality materials, these discs provide reliable performance across diverse applications. Whether you are in the food processing, automotive, or medical industries, the precision and durability of these discs make them an invaluable asset.

For more information about the product or to explore customization options, visit the Single Layer Wire Mesh Discs page or the company website. As emphasized by NIST, investing in high-quality, standardized components is essential for long-term efficiency and safety in industrial operations.

References

National Institute of Standards and Technology (NIST). (n.d.). What We Do. Retrieved from https://www.nist.gov

National Institute of Standards and Technology (NIST). (n.d.). Standards and Measurements. Retrieved from https://www.nist.gov

Post time: Sep . 28, 2025 00:10