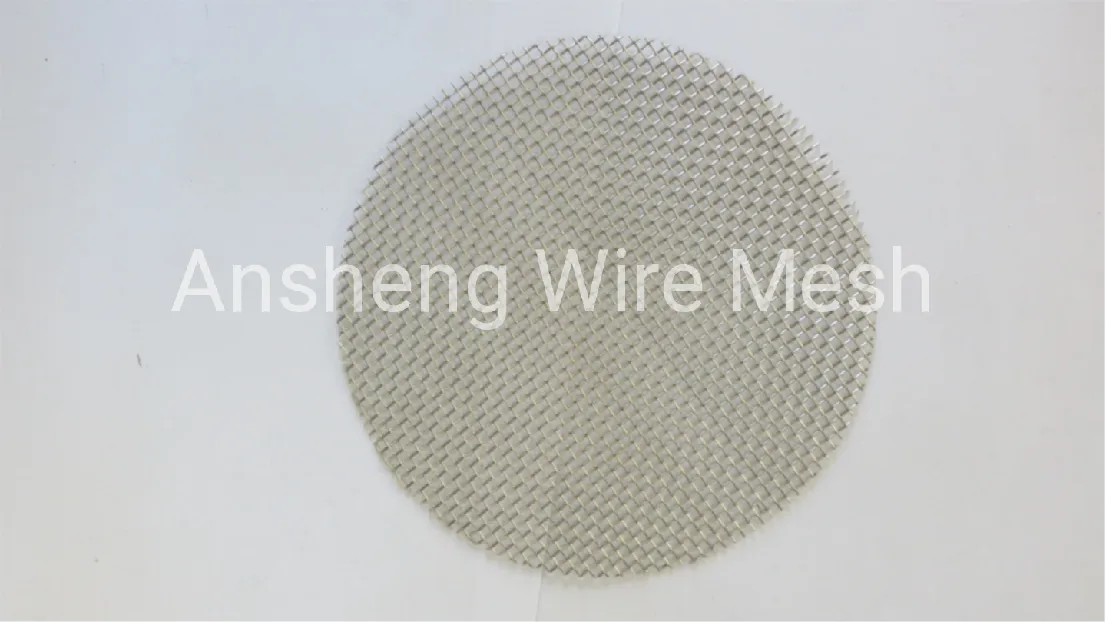

Discover the advanced engineering behind Single Layer Wire Mesh Discs, a product designed to meet the exacting demands of modern industrial and commercial applications. These discs combine precision manufacturing, high-quality materials, and customizable specifications to deliver unmatched performance and reliability. Whether you're involved in filtration, sanding, or industrial screening, this article explores the features, advantages, and technical details that make these wire mesh discs a superior choice.

Key Features of Single Layer Wire Mesh Discs

The Single Layer Wire Mesh Discs are engineered with meticulous attention to detail, ensuring they meet the highest standards of quality and functionality. Here are the core features that define their excellence:

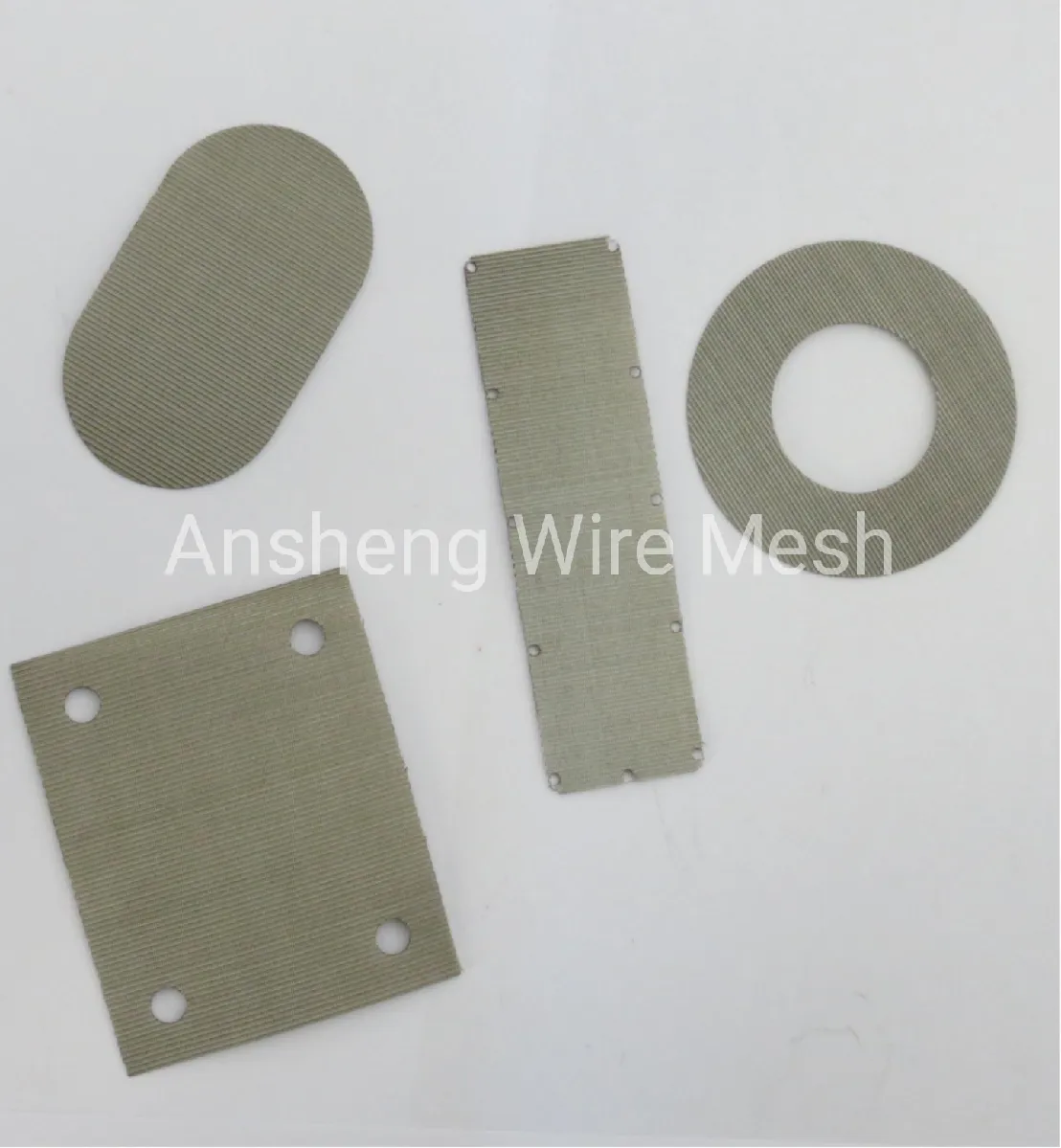

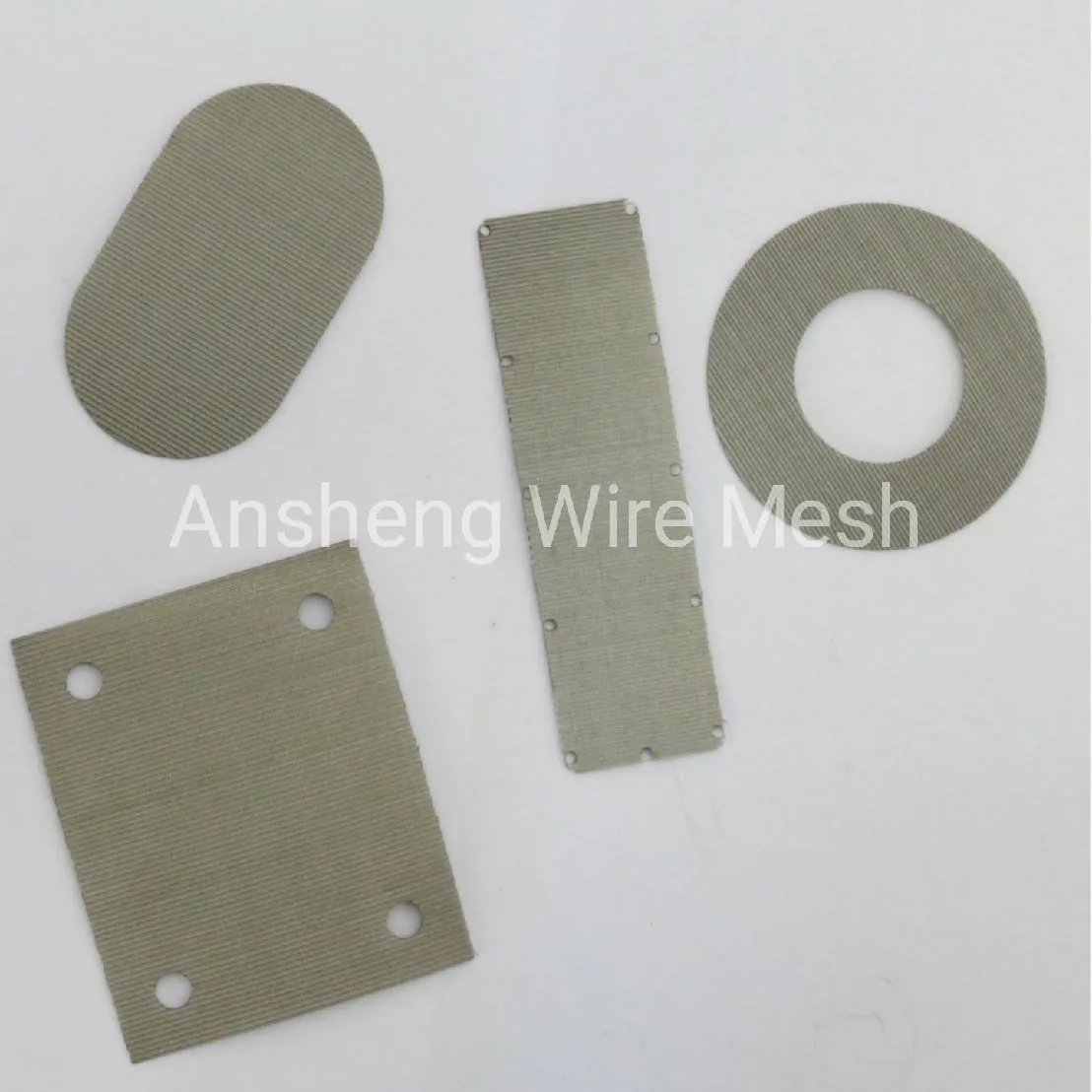

- Shape Regularity: The edges of the mesh are precisely crafted to maintain a neat, distortion-free shape, ensuring seamless integration into machinery and equipment. This design enhances stability during operation and simplifies installation.

- High-Quality Materials: Constructed from premium materials such as stainless steel 304, 316, and galvanized iron, these discs offer exceptional corrosion resistance, strength, and durability. The choice of materials ensures longevity even in harsh environments.

- Fine Weaving: The mesh is tightly and evenly woven, with consistent mesh sizes and no defects like skipping or leakage. This precision guarantees accurate filtration and a visually appealing finish.

- Accurate Specifications: Dimensions such as length, width, and aperture are meticulously controlled to meet design requirements. This precision ensures seamless compatibility with other components and equipment.

Advantages of Customized Wire Mesh Discs

Choosing customized wire mesh discs offers significant benefits over traditional methods of purchasing and cutting materials. Here’s why:

- Cost Efficiency: By eliminating the need for self-cutting, the risk of material waste and rework is drastically reduced. The factory’s precision cutting technology ensures zero waste, lowering material costs and saving time.

- Logistics Optimization: Customized discs are delivered according to your exact requirements, reducing transportation costs and minimizing the environmental impact of shipping large rolls of material.

- Enhanced Performance: The advanced CNC machining equipment and experienced technical team ensure that every disc meets stringent quality standards, guaranteeing reliable performance in critical applications.

Technical Specifications

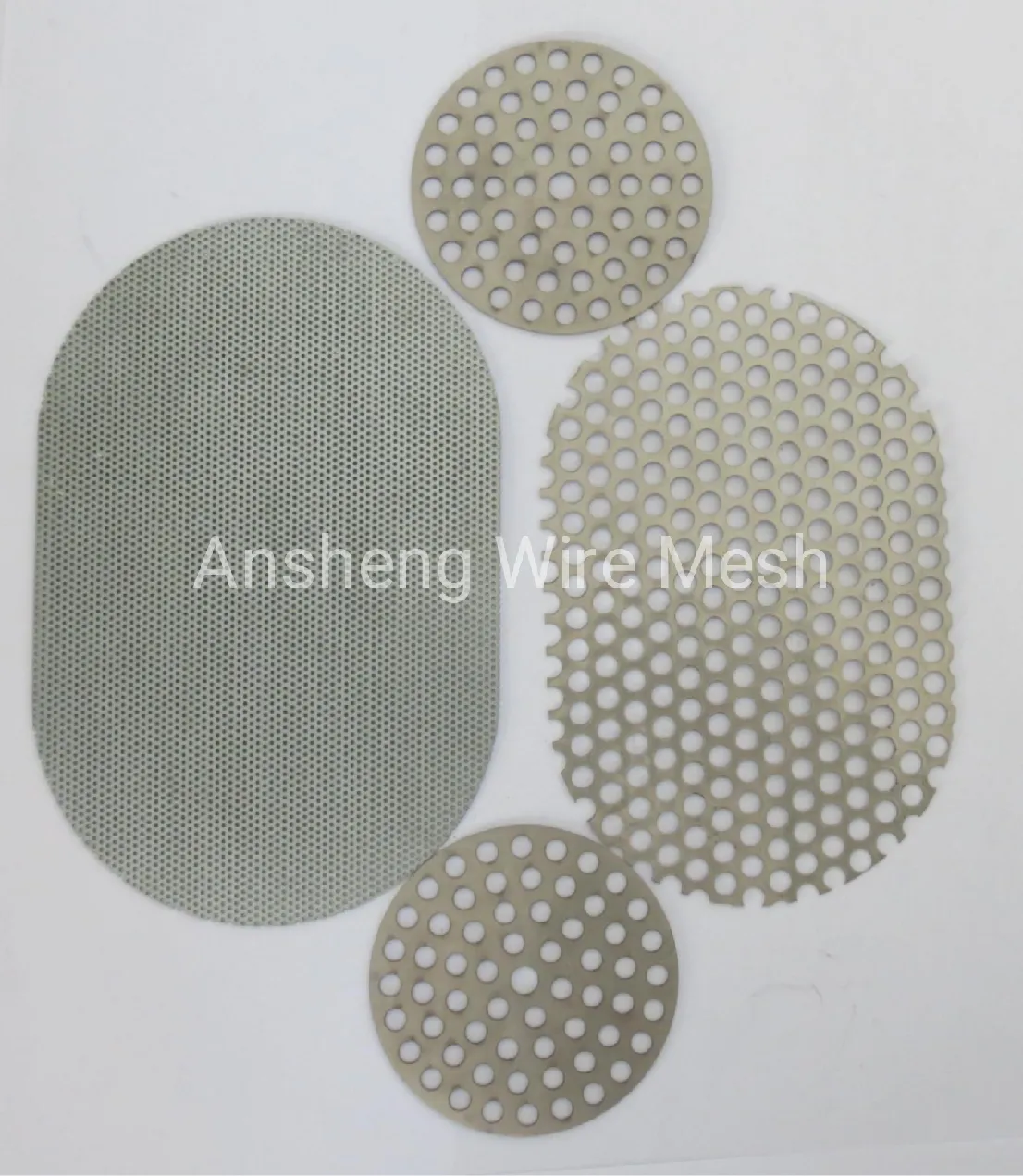

The Single Layer Wire Mesh Discs are available in a wide range of specifications to suit diverse applications. Below is a detailed overview of their technical parameters:

| Parameter | Details |

|---|---|

| Materials | Stainless Steel 304, 201, 316, 316L, Nickel N6, Nickel 200, Low-Carbon Steel, Galvanized, and Others |

| Mesh Size Range | 1-635 Mesh |

| Size Range | 1mm - 1m |

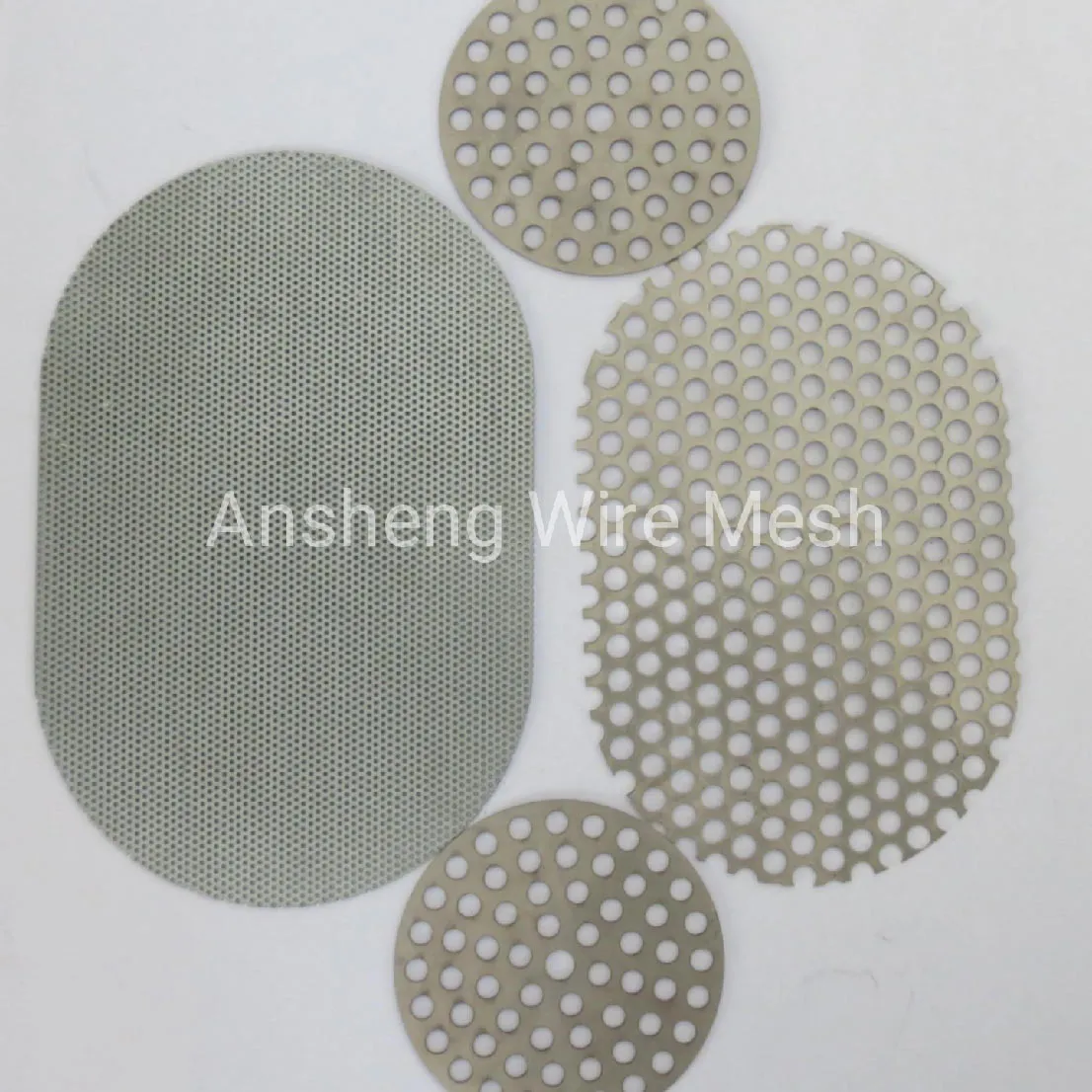

| Shapes | Circular, Square, Oval, Kidney-Shaped, Rectangular, and Irregular Shapes |

| Types | Woven Wire Mesh, Perforated Mesh, Expanded Metal Mesh |

| Surface Finish | Smooth Edges, Burr-Free, and Uniform Mesh Size |

Applications and Use Cases

These wire mesh discs are versatile and find applications in a variety of industries. Some common use cases include:

- Filtration Systems: The precise mesh size and high-quality materials make them ideal for liquid and gas filtration in chemical, pharmaceutical, and water treatment industries.

- Sanding and Polishing: The mesh sanding discs provide consistent abrasion resistance and durability, making them suitable for industrial sanding applications.

- Industrial Screening: The accurate specifications and robust construction ensure reliable performance in screening and separating materials in manufacturing processes.

- Automotive and Aerospace: The discs are used in components requiring high strength and corrosion resistance, such as filters and ventilation systems.

Company Background: Anping County Ansheng Wire Meshes Product Co., Ltd.

Founded in 2005, Anping County Ansheng Wire Meshes Product Co., Ltd. is a leading manufacturer of wire mesh products, specializing in precision-engineered solutions for global markets. The company’s commitment to innovation and quality is evident in its state-of-the-art facilities and rigorous production standards.

With over 15 years of experience, Anping County Ansheng Wire Meshes Product Co., Ltd. has established itself as a trusted partner for industries requiring high-performance mesh products. The company’s advanced CNC machining equipment and skilled technical team ensure that every product meets the highest standards of quality and accuracy.

The company’s dedication to customer satisfaction is reflected in its customizable solutions, which eliminate the need for rework and reduce costs. By focusing on precision, efficiency, and sustainability, Anping County Ansheng Wire Meshes Product Co., Ltd. continues to set benchmarks in the wire mesh industry.

Ensuring Quality Through Industry Standards

The Single Layer Wire Mesh Discs are designed and manufactured in compliance with international standards for material testing and measurement. For instance, the National Institute of Standards and Technology (NIST) provides critical guidelines for material properties and measurement accuracy. These standards ensure that the discs meet the required specifications for strength, durability, and performance.

According to NIST’s research on material testing, the use of high-purity materials and precise manufacturing techniques is essential for achieving consistent quality in industrial components. Anping County Ansheng Wire Meshes Product Co., Ltd. adheres to these principles, ensuring that its products align with the latest advancements in material science and engineering.

Conclusion

The Single Layer Wire Mesh Discs exemplify the perfect blend of precision, quality, and customization. With their advanced manufacturing processes, high-quality materials, and adherence to industry standards, these discs are an ideal solution for a wide range of applications. Whether you need filtration components, sanding discs, or industrial screening solutions, Anping County Ansheng Wire Meshes Product Co., Ltd. delivers products that exceed expectations.

For more information about the Single Layer Wire Mesh Discs or to explore other products, visit Anping County Ansheng Wire Meshes Product Co., Ltd..

Product Images

References

National Institute of Standards and Technology (NIST). (n.d.). Retrieved from https://www.nist.gov/

Post time: Jul . 30, 2025 03:40