Top Wire Mesh Manufacturers from China at Wire & Tube Düsseldorf: Driving Innovation in Filtration

The global industrial sector converges annually at Wire & Tube Düsseldorf, a colossal event that sets the benchmark for innovation in the wire, cable, and tube industries. For B2B decision-makers, this exhibition is an indispensable platform, particularly for those seeking advanced wire mesh and cutting-edge filtration solutions. It’s here that the pulse of the industry is felt, where manufacturers showcase breakthroughs that promise enhanced efficiency, durability, and performance.

The value of Wire & Tube Düsseldorf for the wire mesh industry cannot be overstated. It serves as a vital arena for discovering novel applications, exploring new materials, and forging strategic partnerships that drive future growth. This year, the spotlight shines brightly on Chinese manufacturers, who have consistently demonstrated their capability to deliver high-quality, precision-engineered products – including specialized wire mesh discs, versatile mesh discs, and essential filter discs – to a global clientele. Their blend of technological prowess, extensive production capacities, and competitive pricing makes them crucial partners in a rapidly evolving market.

Industry Trend Spotlight: Precision, Performance, and Sustainable Solutions

The wire mesh industry is currently undergoing a significant transformation, propelled by a global demand for higher precision, enhanced durability, and sustainable manufacturing practices. A critical trend gaining global attention is the escalating need for high-precision woven wire mesh for fine filtration. Industries like pharmaceuticals, petrochemicals, aerospace, and food & beverage processing require filtration media capable of micron-level separation, ensuring product purity and process integrity. This includes an increasing reliance on meticulously crafted wire mesh discs and advanced filter discs, often multi-layered, to meet these stringent requirements.

Another pivotal development is the demand for enhanced corrosion-resistant materials. Applications in aggressive environments, such as chemical processing, marine engineering, and oil & gas exploration, necessitate materials that can withstand extreme temperatures, pressures, and corrosive agents. This has led to widespread adoption of advanced alloys like Duplex stainless steel, Super Duplex stainless steel, and various nickel alloys (e.g., Inconel, Monel, Hastelloy) in wire mesh production. These materials significantly extend the lifespan of components, reducing maintenance costs and improving safety. Simultaneously, the construction and automotive sectors are increasingly utilizing lightweight and strong expanded metal for its superior strength-to-weight ratio, versatility in design, and cost-effectiveness in applications ranging from protective barriers to aesthetic cladding.

The integration of technology is also transforming the sector, with a growing focus on integrated smart filtration systems for IoT applications. These intelligent systems leverage sensors and data analytics to provide real-time performance monitoring, predictive maintenance alerts, and seamless integration into broader industrial IoT ecosystems. This digital transformation optimizes operational efficiency, minimizes downtime, and supports more agile and responsive manufacturing processes.

Market Dynamics & Future Outlook:

The global wire mesh market is projected for robust and steady growth. This expansion is primarily fueled by accelerating industrialization across developing economies, increasingly stringent environmental regulations (which elevate the demand for advanced filtration solutions), and significant global infrastructure development projects. Analysts estimate a Compound Annual Growth Rate (CAGR) of approximately 4-6% over the next five years, underscoring the vital and expanding role of wire mesh across diverse industrial, commercial, and consumer applications.

Key Emerging Focus Areas:

- Sustainable Manufacturing Processes: A growing emphasis on energy-efficient production, waste reduction, and the integration of recyclable or sustainably sourced materials in wire mesh manufacturing, aligning with global environmental goals.

- High-Performance Alloys and Composites: Continued research and development into novel materials that can withstand even more extreme conditions, critical for next-generation applications in aerospace, energy, and advanced manufacturing.

- Automation and AI in Mesh Production: Implementing advanced robotics, artificial intelligence, and machine learning to optimize weaving, welding, cutting, and fabrication processes. This enhances precision, reduces labor costs, and speeds up the production of complex components like intricate wire mesh discs and custom mesh sanding discs.

- Customized Design Solutions: The ability to engineer highly bespoke wire mesh products to meet unique client specifications, covering everything from specific pore sizes and material compositions to specialized geometries for filter disc assemblies in niche applications.

Profiles of Leading Wire Mesh Innovators at Wire & Tube Düsseldorf

Wire & Tube Düsseldorf serves as a global stage where the wire mesh industry's titans and innovators present their latest advancements. Among the diverse array of exhibitors, a few companies consistently stand out for their leadership, commitment to quality, and forward-thinking solutions.

Featured Innovator: Anping County Ansheng Wire Meshes Product Co., Ltd.

Hailing from Anping County, globally recognized as the "Hometown of Wire Mesh," Anping County Ansheng Wire Meshes Product Co., Ltd. stands as a beacon of excellence in the manufacturing sector. With an impressive legacy spanning over 30 years of manufacturing experience, Ansheng has honed its craft, emerging as a trusted name synonymous with high-quality and reliable wire mesh products.

Ansheng's extensive product range is designed to cater to a vast spectrum of industrial needs, showcasing their versatility and deep technical expertise:

- Stainless Steel Wire Mesh: Offering unparalleled corrosion resistance, high tensile strength, and durability for demanding environments.

- Woven Wire Mesh: Available in an array of weave patterns (plain, twill, Dutch) and precise mesh counts, essential for fine screening, separation, and filtration applications.

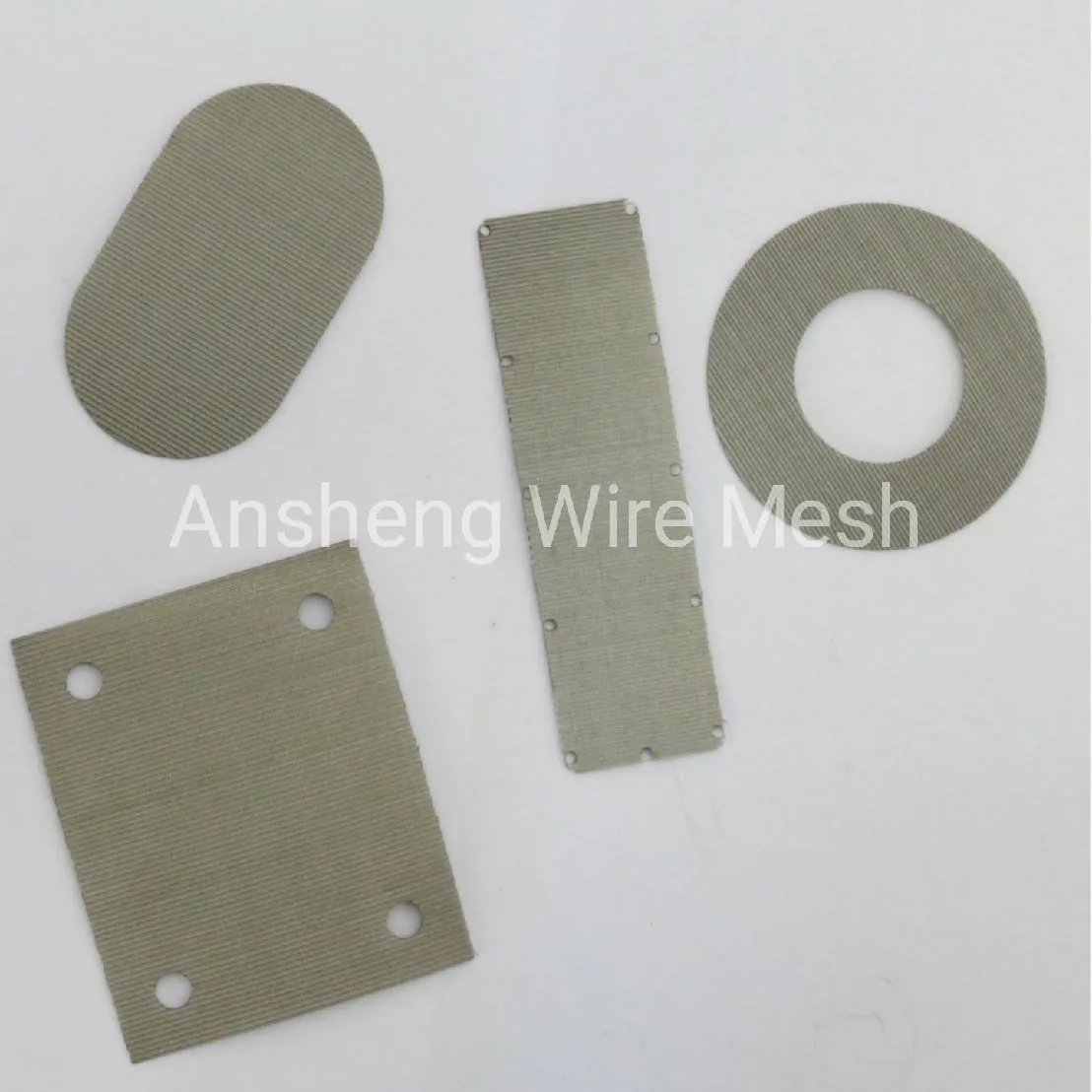

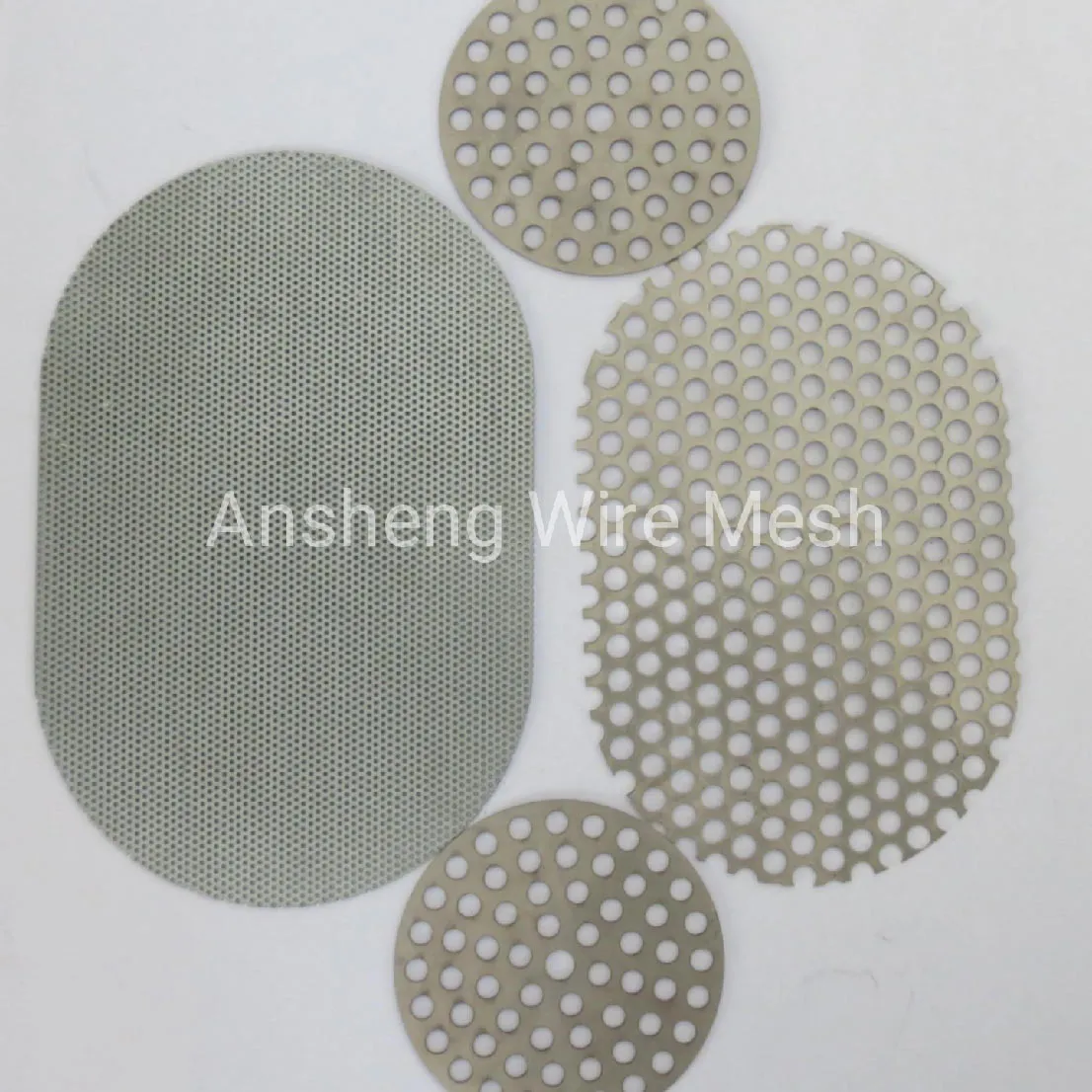

- Filter Meshes & Discs: Specializing in precision-engineered filtration media, including single-layer and multi-layer wire mesh discs, custom-sized mesh discs, and robust filter discs designed for superior efficiency and extended operational life. They also produce specialized mesh sanding discs for surface preparation.

- Perforated Metal: Customized for both functional and aesthetic purposes, utilized in architectural design, sound dampening, and industrial screening.

- Expanded Metal: Valued for its unique strength-to-weight ratio, offering secure and versatile solutions for guarding, flooring, and reinforcement.

A cornerstone of Ansheng's operational philosophy is their robust quality control processes. From the meticulous selection of raw materials to sophisticated in-process monitoring and comprehensive final product inspections, every stage of manufacturing adheres to stringent international standards. This unwavering commitment ensures that each wire mesh disc or filter disc leaving their facility delivers consistent performance, reliability, and precision. This dedication to quality has been instrumental in fostering their strong export capabilities to global markets, solidifying their reputation as a trusted international supplier.

Moreover, Ansheng distinguishes itself through its expertise in customized solutions for diverse industrial applications. Understanding that off-the-shelf products often fall short of highly specific requirements, their engineering team collaborates closely with clients. This bespoke approach allows them to design and manufacture tailored wire mesh products – whether it’s a unique `mesh disc` geometry, specific micron ratings for `filter discs`, or a specialized material combination – ensuring optimal functionality and integration into complex systems.

Examples of Anping County Ansheng Wire Meshes Product Co., Ltd.'s high-precision wire mesh discs and filter discs, demonstrating quality and customization.

Other Global Leaders in Wire Mesh Manufacturing:

- Bekaert (Belgium): A world-leading independent producer of steel wire products, Bekaert is renowned for its advanced materials science and coating technologies. They offer an extensive portfolio of wire mesh for various industrial, agricultural, and construction applications, emphasizing durability and innovative solutions.

- TWP Inc. (USA): A prominent supplier known for its vast inventory of wire mesh and custom fabrication services. TWP Inc. caters to a broad range of industries, providing high-quality mesh in diverse materials and specifications, including precision-cut wire mesh discs and `filter disc` configurations.

- Hebei Jinhai Wire Mesh Co., Ltd. (China): Another significant Chinese manufacturer with a comprehensive product line that spans stainless steel wire mesh, galvanized wire mesh, and various fence products. They are recognized for their commitment to quality, cost-effectiveness, and strong presence in both domestic and international markets.

- GKD – Gebr. Kufferath AG (Germany): A global leader specializing in technical weaves and architectural meshes. GKD is celebrated for its highly specialized woven metal meshes used in demanding filtration, processing, and architectural projects, embodying precision German engineering and innovative textile structures.

Market Outlook & Opportunities: Navigating Tomorrow's Industrial Demands

The future trajectory of the wire mesh industry is marked by dynamic shifts in buyer demand and the emergence of transformative technological paradigms. Forward-thinking buyers are increasingly prioritizing not only high-performance materials but also holistic solutions that offer superior efficiency, extended longevity, and seamless adaptability to evolving operational landscapes. This trend points towards a strong demand for suppliers who can deliver bespoke solutions, from specialized wire mesh discs to comprehensive integrated filtration units, that can be perfectly tailored to their unique requirements.

Substantial opportunities are unfolding within the domains of automation, smart manufacturing, and digital integration. The incorporation of advanced robotics, artificial intelligence, and sophisticated sensor technology into wire mesh production lines is set to revolutionize precision, minimize human error, and dramatically accelerate production cycles. For intricate products like multi-layered `filter disc` assemblies or highly specific `mesh sanding discs`, automation ensures unparalleled consistency and quality. This paradigm shift also extends to the application of wire mesh, where smart filtration systems, powered by IoT capabilities, can continuously monitor performance, anticipate maintenance needs, and dynamically optimize operational parameters in real-time. Such advancements lead to significant cost savings, reduced downtime, and enhanced regulatory compliance.

Sustainability has transcended its role as a niche concern to become a central pillar driving innovation across the industry. Manufacturers who can demonstrate responsible sourcing, eco-friendly production processes, and offer products with extended lifespans or robust recyclability will undoubtedly gain a decisive competitive advantage. This includes pioneering the development of wire mesh from recycled materials and designing `filter disc` solutions that inherently minimize waste generation and energy consumption throughout their lifecycle. The accelerating demand for green technologies and environmentally responsible processes will continue to steer the industry towards more sustainable practices, creating new market segments and fostering long-term resilience.

Buyer & Business Takeaways: Strategic Partnerships for Enduring Success

For B2B decision-makers, the act of investing in high-quality wire mesh products and sophisticated filtration solutions transcends a mere procurement decision; it represents a strategic commitment to optimizing operational efficiency, ensuring product integrity, and securing long-term profitability. Whether the requirement is for a delicate wire mesh disc crucial for precision filtration or a robust expanded metal for critical structural reinforcement, the selection of the right manufacturing partner profoundly impacts overall performance and cost efficiency.

Tips for Strategic Partnerships with Chinese Manufacturers:

- Prioritize Quality Assurance & Certifications: Beyond competitive pricing, prioritize manufacturers who demonstrate rigorous quality control, hold international certifications (e.g., ISO 9001), and have a verifiable track record of delivering consistent product quality. This is especially crucial for mission-critical components like precision filter discs.

- Leverage Customization Capabilities: Many leading Chinese manufacturers, including Anping County Ansheng, offer extensive customization services. Clearly articulate your precise specifications for specialized `wire mesh discs` or unique `mesh sanding discs` to ensure the final product perfectly aligns with your application's demands.

- Assess Communication & Support Infrastructure: Opt for partners who provide clear, proactive communication channels and robust pre-sales and after-sales support. Effective, transparent communication is essential for bridging geographical distances and ensuring successful project execution.

- Evaluate Long-Term Value & Innovation Capacity: While initial cost-effectiveness is a significant advantage, assess the overall value proposition, including product lifespan, minimal maintenance requirements, and the supplier's ongoing investment in R&D and innovation.

- Engage at Industry Trade Fairs: Events like Wire & Tube Düsseldorf offer an invaluable opportunity to meet manufacturers face-to-face, physically inspect product quality, discuss technical requirements in detail, and cultivate personal business relationships.

To truly future-proof your procurement and operational strategies within the rapidly evolving wire mesh market, consider integrating these strategic approaches:

- Embrace Continuous Innovation: Actively stay informed about advancements in materials science, cutting-edge manufacturing techniques, and emerging smart technologies. Partner with manufacturers who are dedicated to R&D and can offer innovative solutions to your most complex challenges, such as next-generation `mesh disc` designs.

- Prioritize Sustainability: Systematically integrate environmental considerations into your entire procurement process. Choosing sustainable wire mesh solutions not only enhances your corporate brand image but also ensures compliance with increasingly stringent global environmental regulations.

- Diversify Your Supply Chain for Resilience: While Chinese manufacturers offer substantial advantages in terms of capability and cost-effectiveness, fostering a diversified supply chain enhances resilience against potential geopolitical, logistical, or economic disruptions.

- Seek Value-Added Services: Look for manufacturing partners who offer more than just physical products. Prioritize those who provide comprehensive engineering support, rapid prototyping for custom `wire mesh discs`, and robust logistical solutions to streamline your operations.

Conclusion: Your Gateway to Wire Mesh Excellence

Wire & Tube Düsseldorf undeniably stands as an unparalleled global benchmark for the wire mesh market. It offers a unique convergence of groundbreaking innovation, profound industry expertise, and invaluable business opportunities. It is at this prestigious event where the future trajectory of industrial filtration and advanced material solutions is charted, and where crucial, long-lasting partnerships are meticulously forged. The prominent presence and advanced manufacturing capabilities of leading Chinese manufacturers, particularly specialized producers like Anping County Ansheng Wire Meshes Product Co., Ltd., unequivocally highlight their pivotal role in supplying high-quality, customized, and cost-effective solutions tailored to meet the intricate and evolving demands of today's diverse industries.

Regardless of your specific requirements – whether it's for ultra-precision wire mesh discs, robust filter discs, specialized `mesh sanding discs`, or any other sophisticated wire mesh product – Wire & Tube Düsseldorf powerfully underscores the global interconnectedness of the industry and the wealth of innovative options readily available. By proactively engaging with these leading manufacturers, B2B decision-makers can confidently ensure they are equipped with the most advanced materials and cutting-edge technologies to drive their own organizational success and maintain a competitive edge in a dynamic global marketplace.

Ready to elevate your filtration and material solutions with precision-engineered wire mesh products?

Discover the comprehensive range of high-quality single-layer filter discs and other advanced wire mesh products from Anping County Ansheng Wire Meshes Product Co., Ltd.

Visit Ansheng's Filter Disc Product PagePost time: Sep . 27, 2025 05:45