2023 Global Market Size: $4.5 Billion (Source: Statista, 2023).

Top Demand Sectors: Water treatment (28%), Oil & Gas (19%), Construction (15%), Food Processing (10%), Metallurgy (8%), Others (20%).

| Parameter | Stainless Steel Mesh Fabric | Stainless Woven Wire Mesh | Stainless Steel Grid Mesh |

|---|---|---|---|

| Material Grade | SS304, SS316, SS316L | SS304, SS316 | SS304, SS316, Duplex SS |

| Typical Mesh Count (per inch) | 4–400 | 8–300 | 1.5–50 |

| Wire Diameter | 0.02–2.0 mm | 0.03–1.2 mm | 1.5–5.0 mm |

| Surface Finish | Annealed, Polished | Polished, Unpolished | Mill Finish, Painted |

| Corrosion Resistance | EXCELLENT | EXCELLENT | Good – Excellent |

| ISO/ANSI Compliance | ISO 9044, ANSI/AWS | ISO 4783, ASTM E2016 | ISO 16120, EN 10223 |

| Operating Temp. Range | -200 ~ 600°C | -150 ~ 550°C | -100 ~ 480°C |

| Customization | Yes | Yes | Yes |

(High-purity stainless/nickel wires) → Wire Drawing

(CNC, laser-controlled gauges) → Weaving/Twilling

(Automated shuttle loom) → Heat Treatment

(Annealing, stress relief) → Surface Finishing

(Ultrasonic cleaning, passivation) → Quality Inspection

(ISO, ANSI certified) → Packaging & Shipping

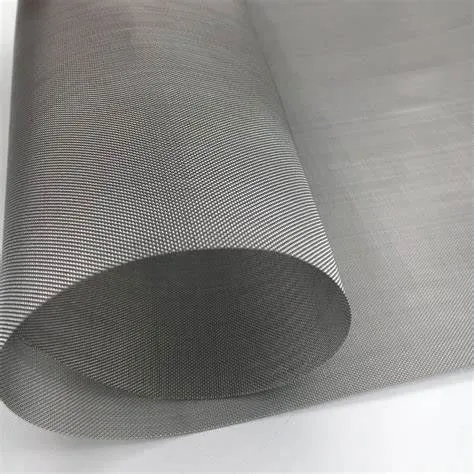

Fig.1: CNC weaving of stainless steel mesh fabric

- Material: Nickel alloys, SS304, SS316, and custom duplex grades for enhanced corrosion resistance.

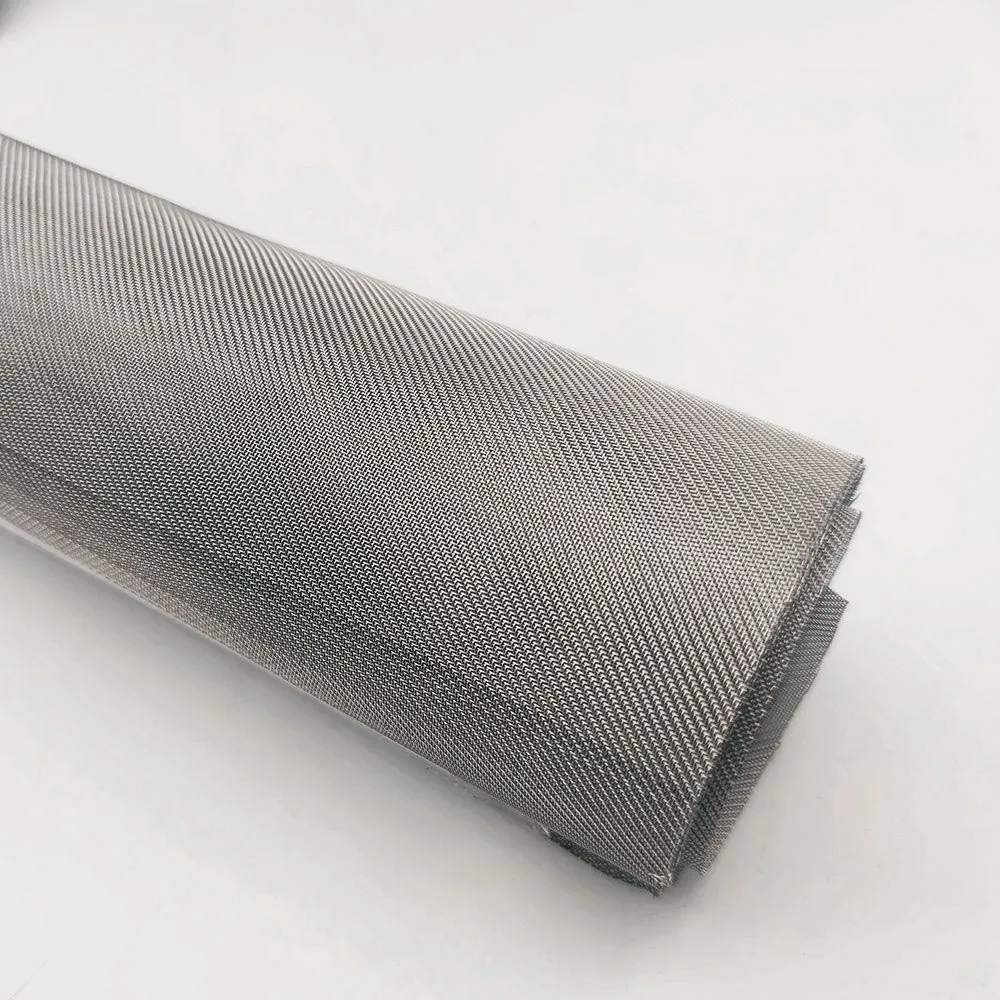

- Process: Twill weave allows tight apertures with increased flexibility and strength, critical for high-precision filtration.

- Inspection: 100% lot-wise tested under ISO 9044, with optional ANSI and FDA compliance on request.

Product URL: https://www.anshengfilterscreen.com/nickel-twill-weave-wire-mesh.html

| Property | Nickel Twill Weave Wire Mesh | Standard Stainless Woven Mesh |

|---|---|---|

| Alloy | Nickel 200/201, NiCr alloys | SS304, SS316 |

| Weave Type | Twill Weave | Plain, Twill, Dutch |

| Mesh Count (per inch) | 10–400 | 4–400 |

| Wire Diameter | 0.025–1.2 mm | 0.02–1.0 mm |

| Corrosion Resistance | Superior (Alkali, Acid, Chloride) | Excellent to Moderate |

| Operating Temperature | -196°C ~ 900°C | -200°C ~ 600°C |

| ISO/ANSI Compliance | ISO 9044, ASTM E2016 | ISO 4783, ASTM E2016 |

| Custom Form Factors | Rolls, Discs, Pleated Elements | Rolls, Panels |

| Sample Delivery | 7–10 days | 10–15 days |

- Petrochemical filtration, inline screens, demister pads (anti-corrosion, up to 900°C)

- Pharmaceutical, food processing (FDA & EU-compliant mesh available)

- Desalination, municipal water supply, brewing filtration

Fig.2: Surface detail of stainless steel mesh fabric (Nickel Twill Weave)

Fig.2: Surface detail of stainless steel mesh fabric (Nickel Twill Weave)

(Higher is Better)

Nickel Twill Weave delivers unmatched corrosion resistance, stable tensile strength at high temperatures, and proven dominance in demanding liquid filtration sectors.

- Longevity & Durability: Up to 20 years of service in industrial applications, reducing lifecycle costs.

- Corrosion Protection: Nickel-enriched alloys outperform conventional stainless steel, especially in chloride/acidic media (resistance up to 98%).

- Precision Filtration: Meshes from 5 μm to 4000 μm, supporting microfiltration to structural screening.

- Certification: Full traceability, ISO 9044, ASTM, ANSI, and—on demand—FDA/EN 1935 compliance for food/pharma sectors.

- Eco-friendly: 100% recyclable, low VOC manufacturing; supports sustainable engineering initiatives.

| Vendor/Product | Main Alloy | ISO/FDA Cert. | Customization | Lead Time* | After-sales |

|---|---|---|---|---|---|

| Ansheng Nickel Twill | Nickel 200, NiCr/SS316 | ISO 9044 / FDA on request | Full (mesh/roll/disk) | 7–14 days | Global 24/7 |

| Competitor A (EU) | SS316, NiCr | ISO 4783 | Limited | 15–30 days | Business hours only |

| Competitor B (US) | SS304, SS316 | ASTM, FDA | Moderate | 18–25 days | Business hours |

Available Customizations:

- Mesh count: 5–400 (micron support as low as 5μm)

- Weave: Plain, twill, Dutch, reverse Dutch

- Alloy: Nickel 200/201, SS304, SS316, Monel, Inconel

- Width/Length: Up to 2.5m width, 100m coils, or custom cut panels/discs

- Finishing: Passivated, polished, painted (for grid mesh)

- Certification: ISO, ASTM, EN, or FDA as needed

Warranty & Support: 1–3 years standard warranty, prompt technical support, and traceable batch QA records.

●Problem: Standard meshes corroded in saline, high-temp conditions.

●Solution: Nickel Twill Weave Wire Mesh deployed (mesh size 40μm, Nickel 201), fully ISO 9044 tested.

●Result: 400% increase in operational lifespan, zero corrosion over 24 months, reduced maintenance downtime by 56%.

●Problem: Frequent mesh fouling & breakdown under acid mist.

●Solution: Custom Nickel Twill mesh with enhanced twill pattern, post-annealed for added durability.

●Impact: Production efficiency up 19%, unscheduled line stops cut by 80%.

●Application: High-volume beverage filtration requiring FDA compliance and easy wash-down.

●Configuration: Nickel Stainless Twill, 85μm, ultrasonic cleaned, FDA/EN certified.

●Result: Stable flow rate, non-contaminating, passed all local food safety tests.

- Certifications: ISO 9044 (Mesh Specification), ISO 9001:2015 (Quality), FDA/EN 1935 (Food Contact) as required.

- Leading Partners: Sinopec, Veolia, Bayer, Tetra Pak, and international EPC contractors.

- Service History: Over 30 years in wire mesh & industrial filtration; 10,000+ global engineering deployments.

- Authoritative Recognition: Cited in Chemical Engineering Progress (AIChE), Filtration+Separation, and ISO/ASTM annual reviews.

Frequently Asked Technical Questions

Production & QA: Full traceability, ISO/ASTM batch testing, video-inspected shipments.

Delivery: Global air/sea logistics—average lead 2~4 weeks.

Warranty: 1–3 years (specifications dependent).

Customer Support: 24/7 hotline, remote video tech support, spare part readiness, ongoing performance monitoring available.

- Statista. (2023) “Global market size of stainless steel mesh fabric” – Source

- ISO 9044:2016 “Industrial wire cloth — Technical requirements and test methods” – ISO Download

- Filtration+Separation Journal, Vol.59, 2021: "Advances in Stainless Woven Filtration Media" – Read Journal

- Forum: Engineering Stack Exchange – “Comparative corrosion resistance of nickel and stainless meshes” – Read Discussion

- Chemical Engineering Progress (AIChE), Oct 2022, "Wire Mesh Innovations for Filtration"

- ASTM E2016-20, “Standard Specification for Industrial Woven Wire Cloth” – ASTM

- Food Contact Materials: FDA 21 CFR 177.2910 Specification

Post time: Aug . 02, 2025 13:00