Plain Weave Mesh is a key solution in the manufacturing industry, specifically within Fabricated metal products and Manufacturing of metal wire ropes and their products. This article explores how Anping County Ansheng Wire Meshes Product Co., Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Plain Weave Mesh Overview

- Benefits & Use Cases of Plain Weave Mesh in Manufacturing of metal wire ropes and their products

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on Plain Weave Mesh from Anping County Ansheng Wire Meshes Product Co., Ltd.

Plain Weave Mesh Overview

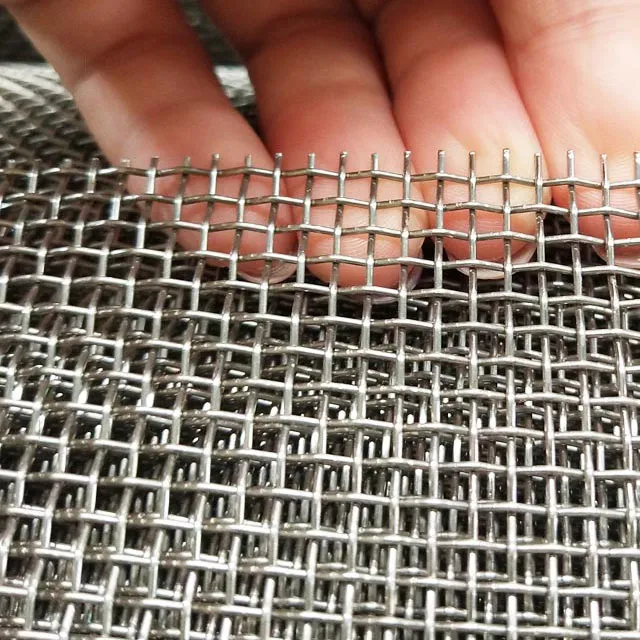

Plain weave mesh, also called plain mesh, is the most fundamental weaving pattern in industrial wire cloth: each warp wire alternates over and under each weft wire, producing a stable, uniform aperture. In fabricated metal products and the manufacturing of metal wire ropes and their products, this geometry delivers dependable filtration, screening, and separation—especially where process consistency, pressure resistance, and repeatable flow rates are critical. Typical specifications range from 2–400 mesh with wire diameters from approximately 0.018–2.0 mm, available in stainless steels (304, 316/316L for corrosion resistance) and carbon steel for cost-optimized plain steel wire mesh needs. Standard widths up to 1.5–2.0 m and roll lengths around 30 m are common; custom sheets, discs, and cut-to-size pieces are widely supplied.

Anping County Ansheng Wire Meshes Product Co., Ltd. manufactures plain weave wire mesh to tight tolerances aligned with ASTM E2016 and ISO 9044 guidelines, ensuring consistent open area and pore size. With advanced looms, precision slitting, and QC inspection at every stage, Ansheng delivers repeatability across batches—vital for B2B buyers running extrusion lines, plating shops, and high-throughput stranding operations. Whether you require plain steel mesh for temporary guards or stainless steel plain weave wire mesh for fine filtration, Ansheng’s engineering support helps you match mesh count, wire diameter, and alloy to your operating pressure, media, and temperature.

Benefits & Use Cases of Plain Weave Mesh in Manufacturing of metal wire ropes and their products

Across wire rope production, plain weave mesh supports multiple mission-critical steps. In wire drawing, stainless steel plain weave wire mesh is used to filter lubricants and emulsions, reducing die wear and improving surface finish. During galvanizing or coating, baskets and strainers made from plain steel wire mesh withstand thermal shock and enable reliable drainage. For polymer sheathing of ropes and strands, multi-layer screen packs built from fine plain weave mesh stabilize melt flow, removing gels and contaminants to minimize line defects. Plants also employ mesh for shot media separation in shot-peening, coolant filtration on stranding machinery, air intake protection, and safety guarding.

The competitive advantages stem from the weave’s dimensional stability, predictable permeability, and ease of fabrication. Plain weave mesh cuts cleanly, forms well, and spot-welds into discs or cylinders with minimal distortion. Stainless 316L options add chemical resistance in pickling environments, while carbon-based plain steel mesh offers a cost-effective choice for non-corrosive service. Anping County Ansheng Wire Meshes Product Co., Ltd. brings deep application expertise—supplying calibrated mesh packs, edge-welded discs, and calendered cloth for enhanced strength—so B2B decision-makers can standardize SKUs, reduce variability, and improve overall equipment effectiveness (OEE).

Cost, Maintenance & User Experience

Total cost of ownership for plain weave mesh hinges on service life, changeover time, and product yield. By selecting the right mesh count, alloy, and pack configuration, plants typically extend on-stream life and reduce unplanned stoppages. Stainless steel plain weave mesh can be back-flushed, ultrasonically cleaned, or solvent-cleaned to enable multiple reuse cycles, spreading the initial purchase cost over more production hours. For non-corrosive duties, plain steel mesh provides compelling value, especially in guard screens, trays, and batch baskets where longevity and low replacement cost matter.

Customers in the fabricated metal products sector report smoother start-ups and fewer screen swaps when transitioning to tightly tolerated cloth from Anping County Ansheng Wire Meshes Product Co., Ltd. Consistency roll-to-roll means extrusion heads and filters can be standardized, trimming setup variance and scrap. Ansheng supports kitted deliveries (e.g., pre-stacked screen packs, labeled by mesh and alloy) to accelerate maintenance. The result is measurable ROI through reduced downtime, stabilized quality, and simplified inventory—advantages that procurement and operations teams can quantify in OEE and cost-per-ton calculations.

Sustainability & Market Trends in manufacturing

Sustainability priorities in metal manufacturing emphasize durability, recyclability, and cleaner operations. Plain weave mesh supports these goals: stainless steel is highly recyclable, and the mesh’s reusability reduces waste in filtration-heavy processes. Compliance with common directives like RoHS and REACH, coupled with documentation for ISO 9001/14001 management systems, helps wire rope producers satisfy customer audits and regulatory demands. As offshore, construction, and lifting markets expand, demand grows for corrosion-resistant meshes (notably 316/316L) and finer cloths that enhance polymer and fluid filtration efficiency.

Anping County Ansheng Wire Meshes Product Co., Ltd. positions itself as a forward-thinking partner by offering material traceability, recyclable packaging options, and engineering guidance that optimizes mesh selection to extend service intervals—lowering energy and consumable usage per output unit. The company’s capability to deliver custom cuts, quick-turn samples, and steady lead times aligns with the market’s push for agile, eco-conscious supply chains. As B2B buyers rationalize suppliers, these attributes make Ansheng a reliable source of plain mesh across global manufacturing hubs.

Conclusion on Plain Weave Mesh from Anping County Ansheng Wire Meshes Product Co., Ltd.

Plain weave mesh—whether specified as plain weave wire mesh, plain steel wire mesh, or stainless steel plain weave cloth—underpins quality and efficiency in fabricated metal products and the manufacturing of metal wire ropes and their products. With consistent apertures, robust strength, and flexible fabrication, it delivers dependable performance from filtration to protection. Anping County Ansheng Wire Meshes Product Co., Ltd. combines precise weaving, tight tolerances, and application know-how to help B2B teams improve uptime and yield.

- Contact us: email: sales@anshengwiremesh.com

- Visit our website: https://www.anshengfilterscreen.com

- Learn more about our product here: Stainless Steel Plain Weave Wire Mesh

Post time: Nov . 14, 2025 09:35