Perforated Metal For Sale is a key solution in the manufacturing industry, specifically within Fabricated metal products and Manufacturing of metal screen mesh. This article explores how Anping County Ansheng Wire Meshes Product Co., Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Perforated Metal For Sale Overview

- Benefits & Use Cases of Perforated Metal For Sale in Manufacturing of metal screen mesh

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on Perforated Metal For Sale from Anping County Ansheng Wire Meshes Product Co., Ltd.

Perforated Metal For Sale Overview

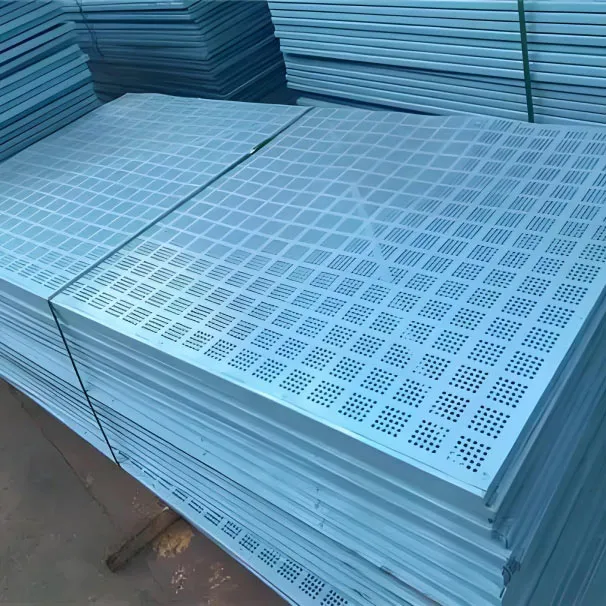

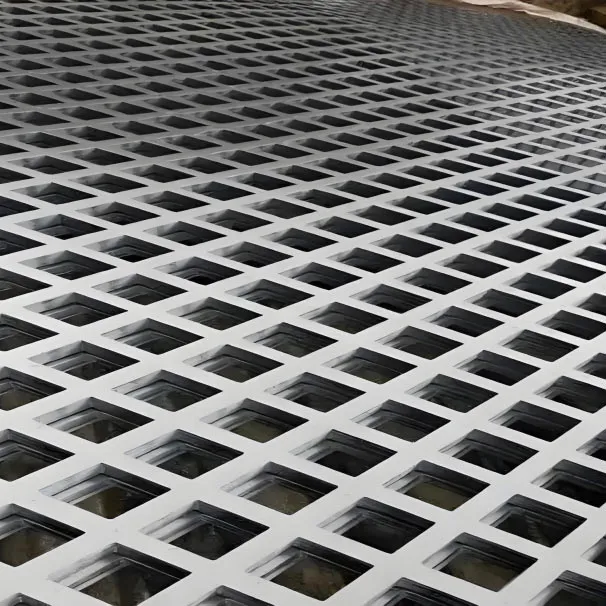

Perforated metal—often called perforated metal mesh, perforated mesh, or perforated metal sheet—is created by punching precise hole patterns into coil or sheet materials such as stainless steel, galvanized steel, aluminum, and copper. In fabricated metal products and the Manufacturing of metal screen mesh, these engineered openings enable controlled flow of air, light, liquids, and sound while maintaining high structural integrity. For B2B buyers, the value lies in repeatable tolerances, predictable open-area percentages, and formability for downstream processes like rolling, bending, and welding.

Typical specifications include thicknesses from 0.3–6.0 mm, hole diameters from 0.5–50 mm, open area from 10–60%+, and patterns such as round, square, slotted, hexagonal, and decorative variants. Surface options include mill, hot-dip galvanized, anodized, or powder-coated finishes. Anping County Ansheng Wire Meshes Product Co., Ltd. supplies tight-pitch, burr-controlled sheets produced on high-speed presses with CNC tooling for consistent sheet flatness and edge quality. In a recent production run for an industrial ventilation customer, a 1.2 mm aluminum sheet with 3 mm round holes and 40% open area delivered optimal airflow while meeting weight and corrosion-resistance targets—illustrating how tailored specs can meet performance KPIs.

Benefits & Use Cases of Perforated Metal For Sale in Manufacturing of metal screen mesh

In metal screen manufacturing, perforated metal is the backbone of filtration, separation, protection, and ventilation systems. Common applications include pre-filters and support layers in multi-stage filters, crusher and sifter screens in aggregates, intake guards for HVAC and compressors, acoustic panels for noise attenuation, machine guards and safety partitions, and architectural facades where airflow and aesthetics intersect. The engineered open area and pattern geometry allow designers to tune pressure drop, particle retention, sound absorption, and stiffness to spec.

- Performance advantages: high strength-to-weight ratio, dimensional stability, and consistent open area for predictable flow and filtration efficiency.

- Manufacturing benefits: excellent formability for deep-drawing or rolling, weldability for frames, and compatibility with coatings.

- Competitive edge: broad die library for common hole patterns plus custom tooling for unique geometries, enabling fast sampling and scale-up.

With decades of category experience, Anping County Ansheng Wire Meshes Product Co., Ltd. helps engineers choose the right perforated metal mesh configuration—balancing alloy, thickness, hole shape, pitch, and open area to meet durability and throughput goals while controlling cost per square meter.

Cost, Maintenance & User Experience

Total cost of ownership for perforated metal sheet hinges on material selection, pattern complexity, sheet size, and finishing. Stainless grades and tighter pitches cost more upfront but can extend lifecycle in corrosive or high-load environments. Many buyers realize ROI through longer service intervals, reduced blinding due to optimized open area, and faster changeouts thanks to flat, burr-free edges. Ansheng’s controlled tolerances reduce downstream rework and scrap—key for lean operations.

- Cost drivers: alloy (SS/aluminum/galvanized), thickness, hole diameter and pitch, open area, sheet or coil format, and secondary processes (leveling, coating, forming).

- Maintenance: smooth surfaces and uniform apertures ease cleaning; corrosion-resistant finishes reduce downtime in wet or chemical environments.

- User feedback: buyers in fabricated metal products report fewer installation issues, better panel fit-up, and consistent airflow/throughput across production lots.

From packaging that prevents edge damage to reliable lead times, Anping County Ansheng Wire Meshes Product Co., Ltd. is set up for repeat orders and scalable delivery—helping procurement teams lock in predictable costs and performance across multi-site programs.

Sustainability & Market Trends in manufacturing

Perforated metal aligns naturally with sustainability goals. Steel and aluminum contain significant recycled content and are fully recyclable at end of life, supporting circularity and potential green building credits. Optimizing open area reduces material mass without compromising strength, enabling lighter assemblies and lower transport emissions. In regulated sectors, buyers increasingly seek materials and coatings that align with RoHS/REACH and low-VOC finishing practices.

Market trends favor higher precision, greater automation, and supply chain transparency. Tighter tolerances, digital QC records, and consistent coil-to-sheet conversion are becoming standard expectations. Anping County Ansheng Wire Meshes Product Co., Ltd. invests in modern punching and leveling equipment, prioritizes material yield, and supports documentation needs on request—helping B2B stakeholders de-risk sourcing while meeting ESG priorities. For applications from acoustic control to solar shading and filtration, demand for high-quality perforated metal mesh continues to grow with the push for energy efficiency and lighter, more durable designs.

Conclusion on Perforated Metal For Sale from Anping County Ansheng Wire Meshes Product Co., Ltd.

From filtration and screening to ventilation and protection, Perforated Metal For Sale delivers predictable performance, long service life, and design flexibility across the manufacturing value chain. Leveraging precise tooling, material expertise, and responsive service, Anping County Ansheng Wire Meshes Product Co., Ltd. is a reliable partner for B2B decision makers seeking quality perforated metal, perforated metal sheet, and custom perforated mesh solutions. Contact us: email: sales@anshengwiremesh.com. Visit our website: https://www.anshengfilterscreen.com.

Post time: Oct . 30, 2025 09:10