- Introduction to Perforated Aluminum: More Than Just Holes in Metal

- Engineering Excellence: Technical Advantages Driving Industry Adoption

- Data Impact: Quantifying the Benefits of Perforated Aluminum Solutions

- Manufacturer Comparison: Key Players and Product Offerings

- Customization Options: Tailoring Perforated Solutions to Your Needs

- Real-World Applications: From Architecture to Industrial Innovation

- The Future of Perforated Aluminum Materials: Sustainable and Innovative Trends

(perforated aluminum mesh)

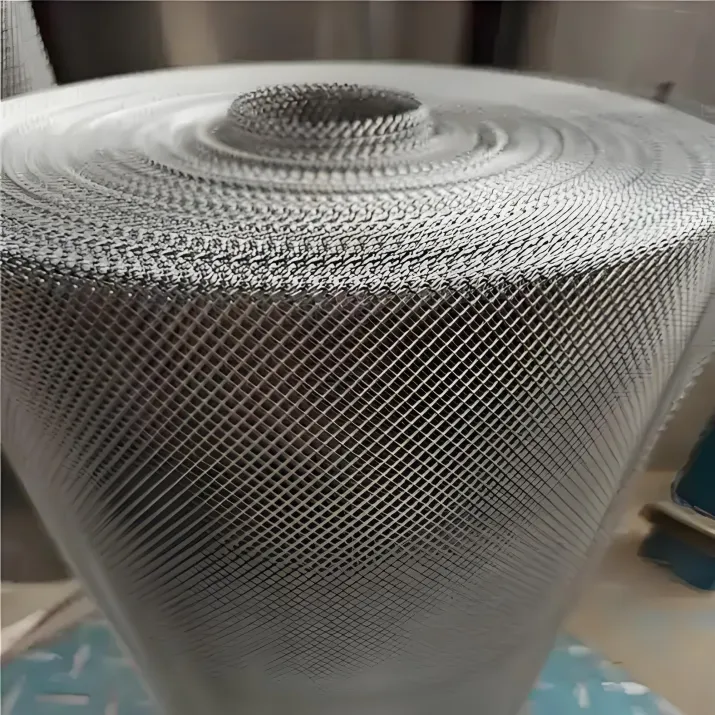

Introduction to Perforated Aluminum Mesh

Modern construction and manufacturing increasingly depend on perforated aluminum mesh

for its unique combination of strength and functionality. This engineered material features precisely punched patterns that transform solid sheets into versatile architectural and industrial components. Unlike traditional solid panels, the perforation process creates materials with tailored airflow, light diffusion, and acoustic properties while maintaining structural integrity.

The manufacturing process begins with high-grade aluminum alloys being fed through CNC punching machines capable of achieving tolerances within ±0.1mm. These machines create hole patterns ranging from micro-perforations at 0.5mm diameter to larger 10mm openings, with open area ratios adjustable from 15% to 70% depending on application requirements. Surface treatments including anodizing, powder coating, or PVDF finishes provide corrosion resistance, maintaining performance in harsh environments from coastal facilities to chemical plants.

Engineering Excellence: Technical Advantages Driving Industry Adoption

Perforated aluminum delivers exceptional strength-to-weight ratios that outperform solid steel alternatives. With typical densities between 2.70-2.80 g/cm³, aluminum mesh achieves structural capacities comparable to carbon steel at just one-third the weight. This advantage translates directly to reduced structural support requirements and simplified installation processes. The precision perforations enhance material properties rather than compromising them - properly engineered patterns increase panel rigidity through optimized load distribution.

Material engineers value the enhanced fire safety characteristics of perforated aluminum composite panels. The aluminum core melts at approximately 660°C (1220°F), significantly higher than many polymer-based alternatives. When perforated and combined with mineral cores, these panels achieve fire ratings up to A2-s1,d0 under European classifications, restricting flame spread while minimizing smoke emission. Thermal performance remains impressive even with open areas exceeding 40%, with conductivity measured between 130-150 W/m·K depending on alloy composition.

Data Impact: Quantifying the Benefits of Perforated Aluminum Solutions

Measurable performance advantages make perforated aluminum solutions cost-effective despite premium material costs. Architectural projects demonstrate 25-40% reduction in HVAC energy consumption due to optimized natural ventilation when compared with fully enclosed structures. Facility managers report 15-18dB noise reduction using perforated acoustic panels, equivalent to decreasing perceived loudness by 60% in industrial settings.

| Performance Metric | Perforated Aluminum Mesh | Perforated Steel | Solid Composite Panel |

|---|---|---|---|

| Weight (kg/m²) | 3.8-7.2 | 9.4-15.7 | 5.9-9.8 |

| Corrosion Resistance Rating | Class A1 (3000hrs) | Class B2 (1000hrs) | Class A2 (1500hrs) |

| Light Transmission (%) | Adjustable 10-85% | Adjustable 5-70% | Fixed 0% |

| Cost Per Square Meter | $95-$185 | $55-$115 | $120-$310 |

| Lifecycle (Years) | 30-50+ | 15-25 | 20-35 |

Project lifecycle analyses consistently demonstrate 15-22% lower total ownership costs over 30 years when specifying perforated aluminum solutions. This cost advantage emerges from minimal maintenance requirements and extended service life exceeding 40 years in most environmental conditions. Unlike painted steel alternatives, aluminum forms a protective oxide layer that self-repairs minor surface damage.

Manufacturer Comparison: Key Players and Product Offerings

Leading suppliers provide distinct advantages in specialized markets. European manufacturers excel in high-precision architectural applications, with companies like Alucobond offering bespoke perforated composite panels featuring digital printing capabilities. North American producers dominate industrial supply chains with offerings like McNICHOLS' extensive perforated aluminum catalog, stocking over 80 standard patterns with same-day shipping on core products.

Specialized applications benefit from niche manufacturers focusing on particular sectors. Manufacturers serving aerospace applications typically provide micro-perforated variants meeting stringent MIL-SPEC standards, while architectural suppliers emphasize aesthetic flexibility with custom patterns mimicking natural textures. Quality differentials become apparent in consistency of hole spacing (industry standard ±0.2mm tolerance), edge finishing quality, and coating adhesion ratings exceeding 10MPa in premium offerings.

Customization Options: Tailoring Perforated Solutions to Your Needs

The true versatility of perforated aluminum emerges in limitless customization possibilities. Pattern design considerations begin with functional requirements: circular holes maximize open area percentages, slot patterns optimize directional airflow, and complex geometric designs serve architectural statements. Designers manipulate variables including hole size (0.5-30mm diameter), spacing arrangements (staggered, straight, or radial), and open area percentage to achieve specific performance metrics.

Material thickness options range from ultra-thin 0.5mm meshes for decorative applications to heavy-duty 6mm sheets for structural cladding. Leading manufacturers maintain digital pattern libraries with over 150 proven designs while offering custom tooling for unique project requirements. Secondary processes transform perforated sheets into three-dimensional forms using press-braking to create curved facades or complex folded assemblies. Recent advances in digital fabrication allow direct translation from CAD models to finished components without traditional tooling constraints.

Real-World Applications: From Architecture to Industrial Innovation

Innovative architectural projects demonstrate perforated aluminum panel capabilities beyond functional requirements. The Beijing Daxing Airport features over 80,000m² of custom-perforated cladding designed with varied hole sizes that modulate daylight while maintaining structural weatherproofing. Each panel underwent computational fluid dynamics analysis to optimize aerodynamic performance around the curved terminal structure.

Industrial applications leverage the material's durability in demanding conditions. Petrochemical facilities use perforated corrugated aluminum walkways that provide slip resistance while allowing corrosive liquids to pass through the surface. Material handling systems incorporate aluminum mesh for conveyor belts where its non-sparking properties and 500kg/m² load capacity ensure safety in explosive environments. Agricultural installations employ perforated aluminum siding offering 65% airflow for natural ventilation while resisting corrosion from ammonia-rich atmospheres.

The Future of Perforated Aluminum Materials

Emerging research focuses on enhancing multi-functional characteristics of perforated aluminum solutions. Nanotechnology surface treatments under development promise self-cleaning properties using photocatalytic coatings that break down organic deposits when exposed to UV light. Material scientists are creating composite structures with embedded phase-change materials within panel cavities to increase thermal mass without compromising the lightweight advantage.

Digital manufacturing advances will transform specification processes through parametric design interfaces. Future clients will manipulate performance requirements - such as target airflow coefficients or structural load capacities - with algorithms instantly generating optimized patterns. Production innovations include laser ablation techniques capable of creating tapered holes that control light diffusion directionally. As industries pursue circular economy principles, new recycling protocols achieve 95% closed-loop material recovery without downgrading aluminum quality.

Perforated aluminum mesh continues demonstrating remarkable adaptability across sectors. Its evolution from industrial screening to sophisticated architectural material illustrates how basic material innovation can transform built environments. With ongoing advances in manufacturing precision and surface engineering, these materials offer solutions to increasingly complex design challenges.

(perforated aluminum mesh)

FAQS on perforated aluminum mesh

Q: What is perforated aluminum mesh used for in architecture?

A: Perforated aluminum mesh serves as a versatile cladding and screening solution. It provides sun shading, ventilation control, and aesthetic appeal for facades. Architects also utilize it for interior design elements and security applications.

Q: How do perforated aluminum composite panels differ from solid panels?

A: Perforated aluminum composite panels feature precision-punched holes through both aluminum layers and core. This significantly reduces weight while maintaining structural rigidity. The perforations also create unique light diffusion effects and improved acoustic properties compared to solid panels.

Q: What advantages does perforated corrugated aluminum offer for industrial applications?

A: Perforated corrugated aluminum delivers exceptional strength-to-weight ratio with its ribbed profile. The added perforations enhance drainage, airflow, and debris filtration. These properties make it ideal for machine guards, walkways, and agricultural building enclosures.

Q: Can perforated aluminum mesh patterns be customized?

A: Absolutely, perforated aluminum mesh allows extensive customization. Hole shapes (round, square, decorative), sizes, spacing, and sheet dimensions can all be tailored. This enables unique designs for specific aesthetic, acoustic, or functional requirements.

Q: How weather-resistant are perforated aluminum facade materials?

A: All perforated aluminum variants offer excellent corrosion resistance. They withstand extreme temperatures, UV exposure, and moisture when properly treated with powder coatings or anodization. Aluminum's natural oxide layer provides additional protection against environmental degradation.

Post time: Jun . 09, 2025 13:48