Nickel Wire Mesh is a key solution in the manufacturing industry, specifically within Fabricated metal products and Manufacturing of metal wire mesh. This article explores how Anping County Ansheng Wire Meshes Product Co., Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Nickel Wire Mesh Overview

- Benefits & Use Cases of Nickel Wire Mesh in Manufacturing of metal wire mesh

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on Nickel Wire Mesh from Anping County Ansheng Wire Meshes Product Co., Ltd.

Nickel Wire Mesh Overview

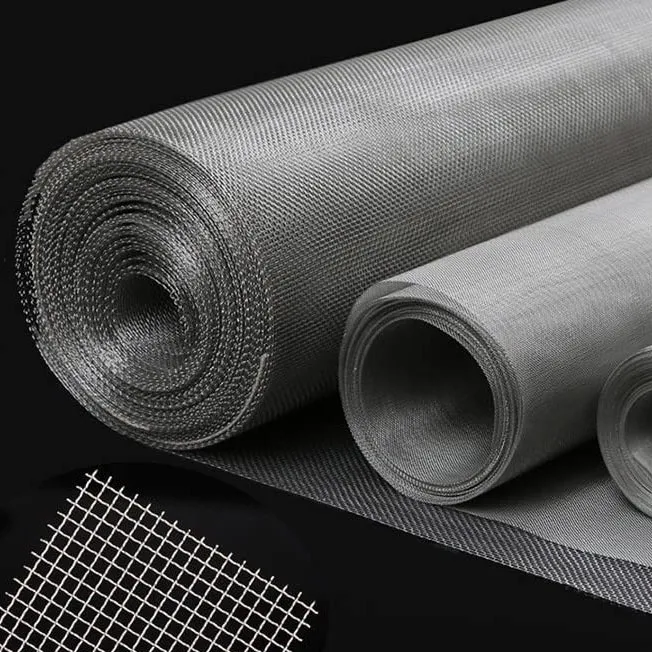

Nickel Wire Mesh is a precision-woven mesh fabricated from commercially pure nickel (Nickel 200/201), engineered for applications where corrosion resistance, electrical/thermal conductivity, and high-temperature stability are mission-critical. In the Fabricated metal products segment and across the Manufacturing of metal wire mesh value chain, pure nickel wire mesh is preferred for aggressive chemical media, alkaline processes, electrolytic cells, battery fabrication, and high-temperature filtration. Anping County Ansheng Wire Meshes Product Co., Ltd. offers plain-weave nickel mesh with tight aperture control, supported by rigorous inspection and material traceability.

Typical specifications include mesh counts from 5–400 mesh, wire diameters from 0.02–2.0 mm, and roll widths of 1000–1220 mm (custom cuts and discs available). Nickel’s melting point is approximately 1455°C; in service, it provides excellent oxidation resistance in air to around 600°C and even higher stability in reducing atmospheres. The plain weave delivers a stable structure, consistent flow, and reliable mechanical integrity during forming, deep drawing, or spot welding. For B2B decision-makers, this translates into predictable performance and fewer process disruptions. Ansheng’s experienced weaving, annealing, and slitting teams help OEMs and processors specify the right mesh count and wire diameter for target permeability, pressure drop, and particle retention.

Benefits & Use Cases of Nickel Wire Mesh in Manufacturing of metal wire mesh

Across chemical processing, energy, and electronics, Nickel Wire Mesh solves tough challenges that stainless steel cannot. In chlor-alkali systems and caustic recovery, nickel stands up to strong alkalis and many neutral salts, ensuring longer filter life. As electrode substrates, current collectors, and gas diffusion layers, it offers outstanding conductivity for electrolyzers, fuel cells, and battery production lines. In high-temperature filtration and catalytic reactors, nickel’s creep resistance and formability maintain aperture stability under thermal cycling. EMI/RFI shielding and precision sieving are additional areas where pure nickel wire mesh excels due to its conductivity and uniform weave.

- Competitive advantages: superior alkali corrosion resistance, high electrical/thermal conductivity, weldability, and stable plain-weave geometry for consistent flow rates.

- Application highlights: electrolytic cells, catalyst supports, hot-gas filtration, battery current collectors, EMI shielding, and acid/alkali media screening.

- Ansheng expertise: custom mesh counts, annealed or bright finishes, precision slitting and disc cutting, quick sampling, and quality documentation for industrial audits.

Cost, Maintenance & User Experience

While Nickel Wire Mesh can carry a higher initial price than common stainless grades, the total cost of ownership often trends lower in corrosive or high-temperature environments. Longer service intervals, fewer unplanned shutdowns, and stable electrical/thermal performance contribute to measurable ROI. Many processors extend changeout intervals by 1.5–3x versus conventional alternative meshes, depending on media chemistry and duty cycle. For B2B operations, that translates into reduced labor time, minimized inventory carrying costs, and improved line uptime.

- Durability and maintenance: nickel’s resistance to pitting and stress corrosion simplifies cleaning. Mesh can often be backflushed, ultrasonically cleaned, or chemically cleaned within compatible media to restore flow.

- User feedback: customers in fabricated metal products and chemical processing note more consistent differential pressure and fewer premature blockages when switching to pure nickel wire mesh with tighter tolerance control.

- Ansheng support: pre-annealed options for easy forming, tailored roll lengths to reduce scrap, and packaging that protects aperture integrity in transit. Technical assistance helps select mesh counts balancing capture efficiency and pressure drop.

Sustainability & Market Trends in manufacturing

Sustainability is reshaping material choices across manufacturing. Nickel is highly recyclable, and pure nickel wire mesh can be reclaimed and reprocessed at end of life, supporting circular material flows. Demand growth in batteries, hydrogen, and advanced chemical processing is accelerating adoption due to nickel’s conductivity, corrosion resistance, and stable performance at elevated temperatures. Regulatory frameworks such as REACH and RoHS, along with customer ESG goals, are pushing suppliers to deliver traceable, low-waste, long-life components that reduce total environmental impact.

- Ansheng’s approach: rigorous raw-material qualification, lot traceability, and scrap recycling programs that recover and return nickel to the supply chain, minimizing waste.

- Market trends: finer mesh counts for precision filtration, tighter tolerance windows supported by digital inspection, and custom cut-to-size parts that reduce on-site trimming and scrap.

- Forward-thinking manufacturing: investment in quality control and application engineering ensures that each Nickel Wire Mesh specification aligns with process efficiency and sustainability targets.

Conclusion on Nickel Wire Mesh from Anping County Ansheng Wire Meshes Product Co., Ltd.

For B2B decision-makers in fabricated metal products and the Manufacturing of metal wire mesh, Nickel Wire Mesh offers dependable corrosion resistance, conductivity, and thermal stability that lower TCO and elevate process reliability. Anping County Ansheng Wire Meshes Product Co., Ltd. combines precise weaving, material traceability, and responsive engineering support to deliver consistent, application-ready mesh—whether you need standard plain weave or custom-cut pure nickel wire mesh parts.

- Recap: an ideal choice for aggressive media, high-temperature service, and electrically demanding duties.

- Reputation: trusted quality control, fast turnaround, and comprehensive documentation from Ansheng.

- Strong CTA: Contact us: email: sales@anshengwiremesh.com — Visit our website: https://www.anshengfilterscreen.com

Post time: Nov . 10, 2025 08:30