Nickel Plain Weave Wire Mesh: an insider’s field note

If you’re speccing filtration or catalysis equipment in 2025, chances are you’ve bumped into Nickel Wire Mesh more than once. To be honest, it’s everywhere now—from battery plants to chlor-alkali, from lab furnaces to precision EMI cages. The buzz isn’t hype: pure nickel meshes handle heat, alkalis, and reducing atmospheres with a calm that stainless sometimes can’t match. Below is what buyers keep asking me, plus what fabricators quietly optimize behind the scenes.

Quick specs (real-world, not just brochure)

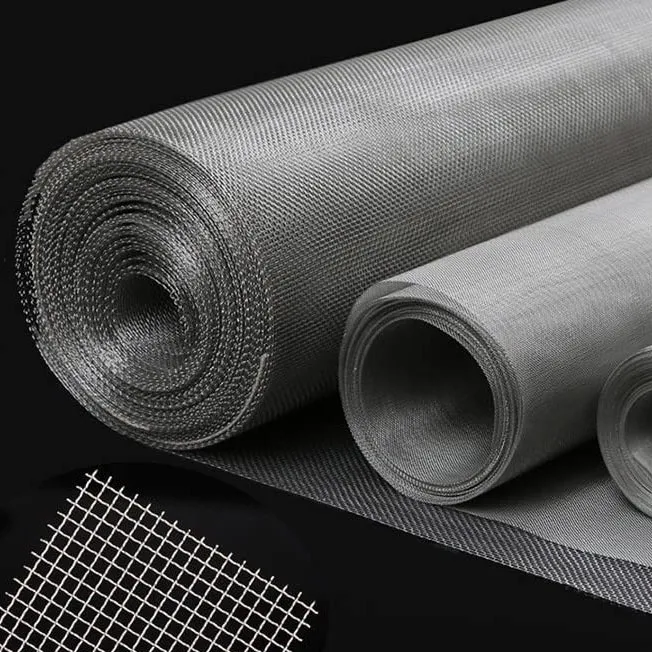

Product: Nickel Plain Weave Wire Mesh. Materials: N6, N4, Nickel 200 (UNS N02200). Weaves: plain and twill for higher strength or tighter openings. Many customers say the consistency in 200–400 mesh is what wins projects.

| Parameter | Typical Range / Note |

|---|---|

| Mesh count | 1–600 mesh (≈5–25,000 μm aperture; real-world may vary) |

| Wire diameter | 0.02–8.0 mm |

| Roll width | Usually 1–2 m; custom widths available |

| Roll length | Standard 30 m; up to 350 m on request |

| Alloy | N6 / N4 / Nickel 200 (high-purity) |

| Tolerances | Per ISO 9044 / ASTM E2016, project-specific |

What’s driving demand

Battery-grade chemicals, green hydrogen, and stricter EMI rules. Actually, the surprise uptick is in high-temp lab furnaces—engineers tell me Nickel Wire Mesh holds its geometry better above 600°C than their previous alloys.

Process flow (how it’s really made)

- Materials: Electrolytic nickel feed → melt & cast → hot/cold drawn to wire (ASTM B160 guidance).

- Weaving: Plain or twill on shuttle looms; tight tension control to stabilize aperture.

- Heat-treatment: Stress relief/anneal for formability and low spring-back (especially 200–400 mesh).

- Finishing: Flattening (if needed), ultrasonic cleaning, oil-free packaging.

- Testing: Aperture/diameter (ISO 9044), chemistry (GB/T 2054), tensile (ASTM E8), flatness checks.

Performance notes and test data

Resistivity ≈0.099 Ω·mm²/m at 20°C; thermal limit ~1455°C melting point; solid oxidation resistance in dry atmospheres. In 168 h neutral salt spray (ASTM B117) most plain-weave Nickel 200 meshes show no red rust; immersion tests (ASTM G31) in mild alkali yield low mass loss—numbers vary with pH and chloride. Practical service life: 2–8 years in alkaline filtration, months to years in hot acids (application-specific, honestly).

Where it’s used (and why)

- Chlor-alkali diaphragms, caustic filtration: Nickel Wire Mesh resists alkali attack.

- Catalyst supports in hydrogenation: clean surface chemistry, stable at temp.

- Battery slurry sieving and conductive paths: decent conductivity, non-sparking.

- EMI/RFI shielding rooms: twill weaves give tighter shielding effectiveness.

- Lab furnaces and thermal baskets: creep resistance and predictable softening.

Feedback? Many customers say assembly scrap dropped when switching to annealed twill around 300 mesh—less breakage on fold lines.

Mini case studies

- A Southeast Asian cathode plant replaced 316L with Nickel Wire Mesh (200 mesh, 0.05 mm). Downtime from blinding fell ≈18% over two quarters, reportedly due to finer yet stable apertures.

- In a pilot PEM electrolyzer rig, twill 100×0.1 mm nickel survived thermal cycling to 450°C with minimal distortion—operator called it “boringly reliable,” which is a compliment.

Vendor snapshot (what to look for)

| Vendor | Strengths | Watch-outs |

|---|---|---|

| Ansheng (Anping, China) | Wide spec range (1–600 mesh), long rolls ≤350 m, fast custom widths | Confirm anneal state per batch |

| EU Mill | Tight tolerances, documentation depth | Lead times, premium pricing |

| Generic Trader | Low MOQs, price | Traceability and QC can vary |

Customization, docs, origin

Custom weaves, calendering, edge trimming, and slit rolls are routine. Typical certificates requested: ISO 9001, material test report (chemistry), RoHS/REACH statements. Ship-from: No.346 Xinying East Street, Anping County, Hebei, China. Lead time for non-stock: around 2–3 weeks for common meshes.

Standards to reference

- ASTM B160 – Nickel rod, bar, and wire specification.

- ASTM E2016 – Industrial woven wire cloth standard.

- ISO 9044 – Industrial wire screens and cloth tolerances.

- ASTM G31 / B117 – Lab corrosion tests (immersion, salt spray).

Post time: Nov . 06, 2025 18:35