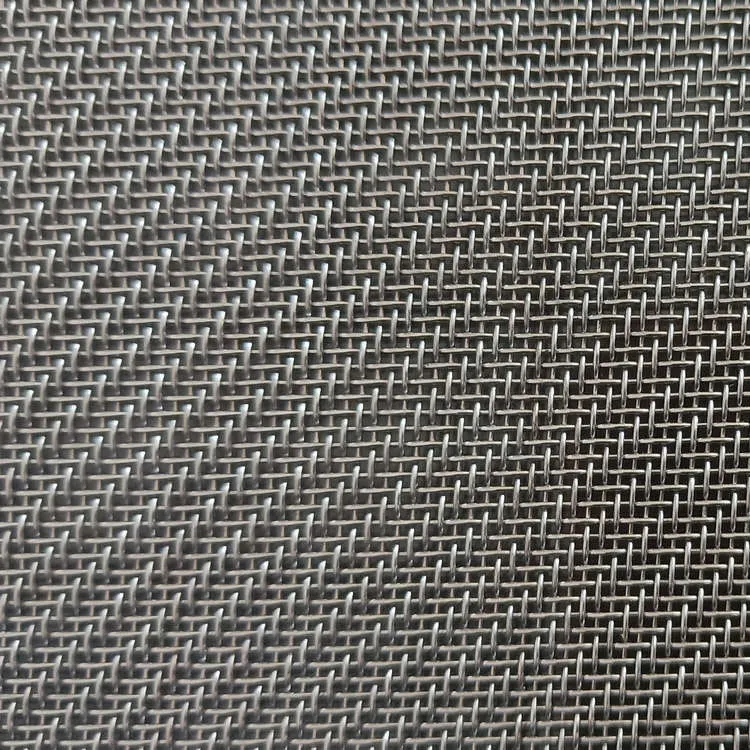

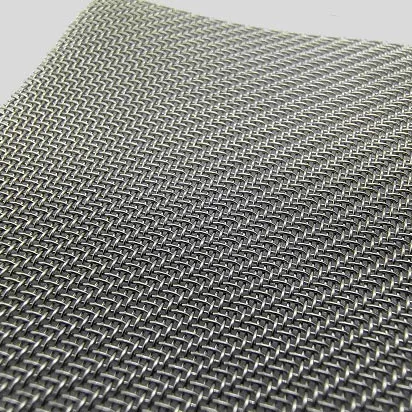

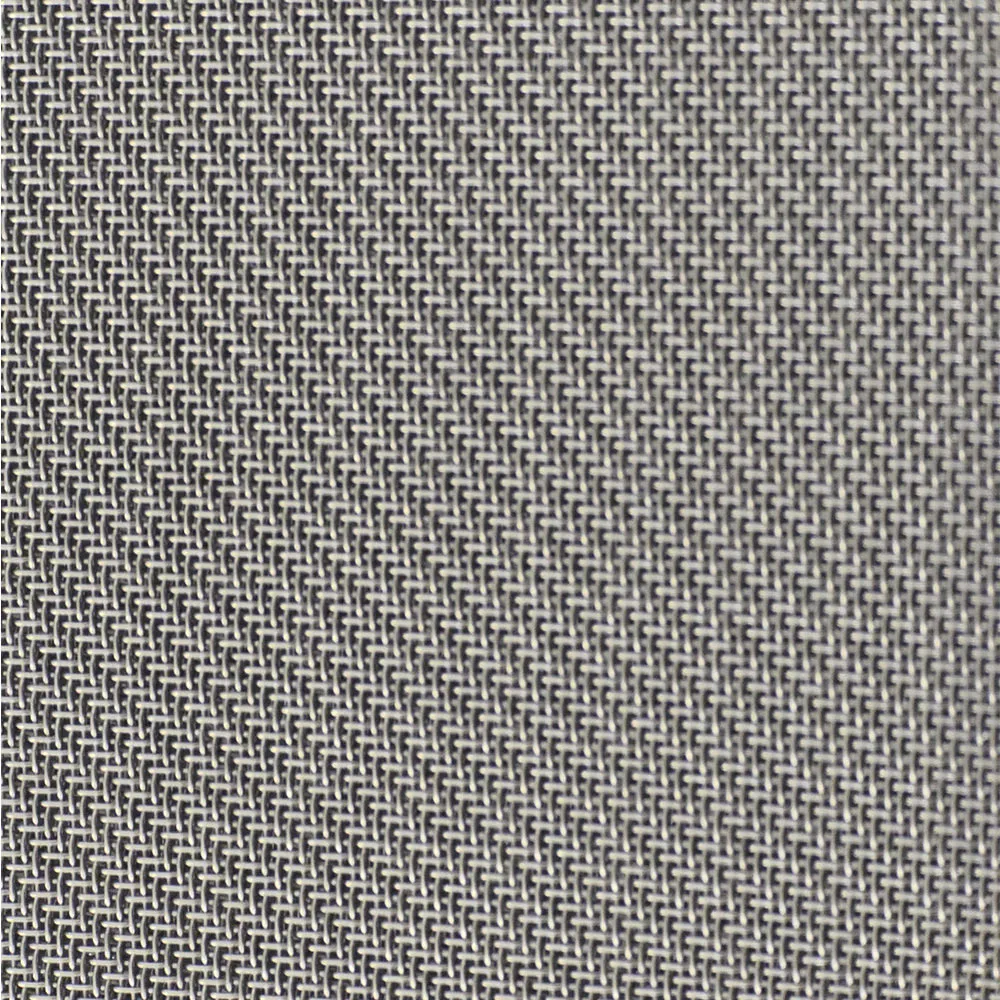

Stainless Steel Twill Weave Wire Mesh: field notes from the factory floor

If you work in filtration or screening, you’ve probably heard the buzz around twill weave mesh. To be honest, the surge isn’t hype—it’s practical. Twill’s diagonal pattern lets you run thicker wires and tighter openings without the cloth becoming brittle. That’s why engineers in chemicals, battery slurry, food refining, and even aerospace keep asking for it. And yes, the price-performance balance in 304/316/316L has been surprisingly stable this year.

At-a-glance product specs

| Product Name | Stainless Steel Twill Weave Wire Mesh (a.k.a. wire cloth, screen, gauze) |

| Materials | 201, 304, 316, 316L (wire per ASTM A580/A580M) |

| Mesh Range | 1–635 mesh |

| Wire Diameter | 1.0 mm – 0.001 mm (≈1000–1 micron wire) |

| Width | 0.915–2.0 m standard; custom on request |

| Roll Length | ≈30 m (real-world may vary ±2%) |

| Weaves | Plain, twill weave mesh, herringbone, dutch, reverse dutch |

| Standards | ISO 9044, ASTM E2016; QC to ISO 9001 |

Process flow, testing, and why twill matters

From No.346 Xinying East Street, Anping County, Hebei (a mesh town if there ever was one), coils arrive, get drawn to target gauge, heat-treated, then woven on digital looms. The diagonal interlacing lets the wires “seat” without over-stressing, so twill weave mesh handles higher differential pressures. Aperture and wire-diameter checks follow ISO 9044; dimensional tolerances follow ASTM E2016. For marine or caustic environments, 316L is popular; samples often run 96–240 h salt spray per ISO 9227 or ASTM B117. Service life? In neutral pH, indoor duty, I’ve seen 5–10 years. Aggressive chemicals: plan maintenance at 12–24 months, depending on ΔP and CIP chemistry.

Where it’s used (and what users say)

- Refining and edible oil polish filtration (≤25 µm cut with twill weave mesh stacks)

- Battery slurry, cathode/anode materials—stable under abrasive shear

- Pharma/API: pre-filtration before sintered media; easy to validate and clean

- Petrochemical screens and demisters where plain weave sags, twill stays put

- EMI shielding and vent panels—low pressure loss with sturdy form

Customer feedback? Many buyers mention fewer ruptures during backflush compared to plain weave. One maintenance manager told me, “We dropped unplanned shutdowns by half after switching to 316L twill weave mesh.” Not a lab study, but it tracks with what we see.

Mini case files

Food oil refinery (SE Asia): 316L twill, 200 mesh, held a steady ΔP profile; roll change intervals extended from 6 to 10 months. Battery plant (EU): 325 mesh twill in slurry prep, 0.035 mm wire, reported 18% fewer screen swaps month-over-month, presumably due to better abrasion tolerance.

Vendor comparison (real-world procurement notes)

| Vendor | Lead Time | Tolerance (aperture) | Standards/Certs | Notes |

|---|---|---|---|---|

| Ansheng (Hebei) | 7–15 days typical | ≈ ±3% (mesh ≥100) | ISO 9044, ASTM E2016, ISO 9001 | Solid weaving range; responsive on custom widths |

| Importer A | 15–30 days | ≈ ±5% | Claims ASTM; limited QC docs | Lower cost, variable lot-to-lot |

| Importer B | 10–20 days | ≈ ±4% | Basic factory CoC | Limited high-mesh capability |

Customization checklist

- Alloys: 201/304/316/316L; passivation or electropolish on request

- Widths up to 2 m; slitting to strips; framed screens ready-to-install

- Mesh 1–635; multi-layer laminates for tighter cuts using twill weave mesh

- Test packs: aperture maps, wire certs, salt spray, tensile per project spec

Origin: No.346 Xinying East Street, Anping County, Hebei, China.

Final tip: when you spec twill weave mesh, pair mesh count with wire diameter, not just micron rating. It keeps pressure drop predictable and avoids over-tight cloth that’s a pain to clean.

Authoritative citations

- ISO 9044: Industrial wire screens and cloth — Technical requirements and tests.

- ASTM E2016/E2016M: Standard Specification for Industrial Wire Cloth.

- ASTM A580/A580M: Standard Specification for Stainless Steel Wire.

- ISO 9227: Corrosion tests in artificial atmospheres — Salt spray tests (and ASTM B117 equivalent).

Post time: Oct . 10, 2025 09:45