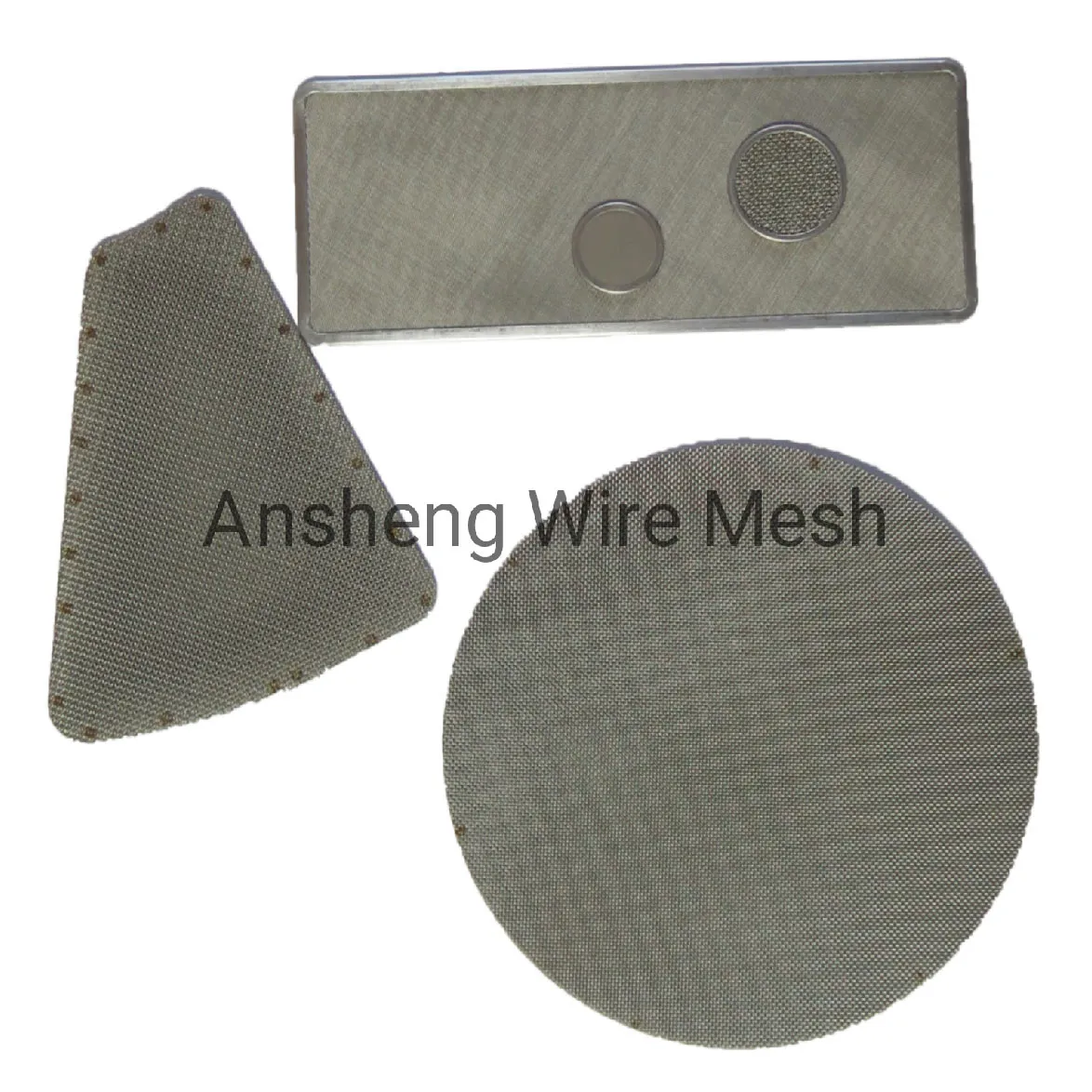

Multi-Layer Mesh With Welding Spots: Durable and Efficient Industrial Abrasive Solutions

Introduction

As a leading manufacturer in the wire mesh industry, Anping County Ansheng Wire Meshes Product Co., Ltd. offers innovative solutions for industrial abrasive applications. Our Multi-Layer Mesh With Welding Spots is designed to meet the demanding requirements of modern manufacturing processes. This article explores the technical specifications, applications, and benefits of this high-performance product.

Product Overview

Technical Specifications

- Material: High-quality steel wire

- Layer Structure: Multi-layer design for enhanced durability

- Welding Spots: Precision-welded points for structural integrity

- Dimensions: Available in 125mm, 150mm, and 225mm sizes (compatible with wire mesh discs and mesh sanding discs)

- Surface Treatment: Anti-corrosion coating for long-term performance

Key Features

- Multi-layer construction provides superior strength and flexibility

- Welding spots ensure even distribution of pressure during use

- Customizable sizes to suit various industrial applications

- Resistant to wear and tear in high-intensity environments

Market Demand and Industry Challenges

The industrial abrasives market requires materials that combine durability with efficiency. Traditional single-layer mesh products often fail under heavy use, leading to frequent replacements and increased costs. Multi-Layer Mesh With Welding Spots addresses these challenges by offering a robust solution that maintains performance even in demanding conditions.

Applications in Industrial Processes

Key Industries

- Automotive Manufacturing: Used for surface preparation and paint removal

- Construction: Ideal for grinding and polishing concrete surfaces

- Metalworking: Effective for deburring and finishing metal components

- Woodworking: Suitable for sanding and shaping wooden surfaces

Company Expertise and Innovation

Anping County Ansheng Wire Meshes Product Co., Ltd. has established itself as a leader in the wire mesh industry through its commitment to quality and innovation. With over 20 years of experience, our company specializes in developing advanced mesh solutions that meet the evolving needs of global manufacturers.

Product Performance and Customer Feedback

Users of Multi-Layer Mesh With Welding Spots report significant improvements in productivity and cost savings. One customer stated, "The welding spots ensure even pressure distribution, reducing the risk of uneven wear. This has increased our operational efficiency by 30%."

Usage Guidelines and Customization

Installation and Maintenance

- Ensure proper alignment with the grinding tool

- Regularly inspect for signs of wear or damage

- Store in a dry environment to prevent corrosion

Customization Options

We offer tailored solutions for specific applications, including:

- Adjustable mesh density

- Specialized coating options

- Custom size configurations

Safety and Compliance

All Multi-Layer Mesh With Welding Spots products comply with international safety standards. Our manufacturing processes ensure minimal environmental impact while maintaining high performance levels.

Packaging and Shipping

Our products are packaged in sturdy, moisture-resistant containers to ensure safe delivery. For bulk orders, we offer customized packaging solutions to meet your specific requirements.

Customer Support and After-Sales Services

We provide comprehensive support to our clients, including:

- Technical consultations

- Product training sessions

- Customized solution development

Contact Us

For more information about Multi-Layer Mesh With Welding Spots, please visit our company website or contact our sales team directly at +86-312-580-3258.

Conclusion

With its advanced design and reliable performance, Multi-Layer Mesh With Welding Spots is an essential solution for modern industrial applications. Discover how our products can enhance your production efficiency and reduce operational costs.

Frequently Asked Questions

Q: What are the available sizes for this product?

A: We offer standard sizes including 125mm, 150mm, and 225mm, suitable for various mesh sanding discs applications.

Q: Can the product be customized?

A: Yes, we provide customization options to meet specific industrial requirements.

Q: How does the welding spot design improve performance?

A: The welding spots ensure even pressure distribution, enhancing durability and reducing the risk of uneven wear during use.

Post time: Jul . 21, 2025 10:20