Multi-Layer Mesh With Welding Spots - High-Quality Wire Mesh Discs for Industrial Applications

At Anping County Ansheng Wire Meshes Product Co., Ltd., we specialize in manufacturing advanced wire mesh products that meet the rigorous demands of modern industrial applications. Our Multi-Layer Mesh With Welding Spots is engineered to deliver exceptional durability, precision, and efficiency across a wide range of industries. Whether you're working on metal surface preparation, automotive manufacturing, or construction, our wire mesh discs are designed to provide superior performance and long-term value.

Understanding the Multi-Layer Mesh With Welding Spots

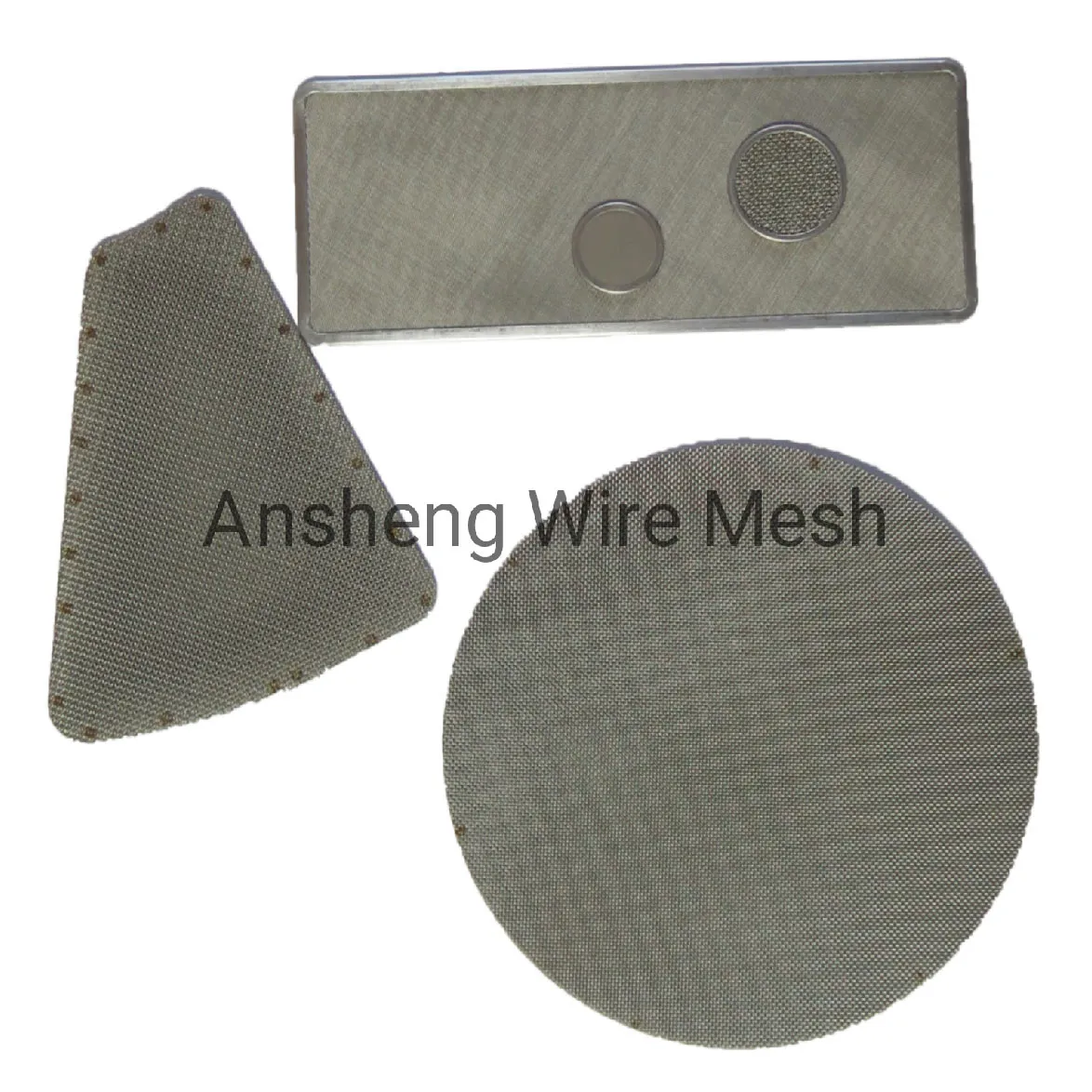

The Multi-Layer Mesh With Welding Spots is a specialized wire mesh disc that combines multiple layers of fine mesh with strategically placed welding points to enhance structural integrity and performance. This design ensures even distribution of force during grinding and polishing tasks, reducing the risk of material deformation and improving surface finish quality. The welding spots act as reinforcement points, preventing the mesh from tearing or warping under high-pressure applications.

Available in multiple sizes, including 125mm mesh sanding discs, 150mm mesh sanding discs, and 225mm mesh sanding discs, our products cater to diverse industrial needs. The multi-layer construction allows for efficient dust removal and heat dissipation, making them ideal for high-speed grinding operations.

Key Advantages of Multi-Layer Mesh With Welding Spots

1. Enhanced Durability

The welding spots on our wire mesh discs are designed to withstand extreme conditions. Unlike traditional single-layer mesh discs, the multi-layer structure provides additional support, minimizing wear and tear during prolonged use. This makes our products a cost-effective solution for industries that require high-volume grinding and polishing tasks.

2. Superior Surface Finish

Our mesh sanding discs 125mm and other variants are crafted to deliver a consistent and smooth surface finish. The precise mesh pattern ensures uniform contact with the workpiece, reducing the likelihood of scratches or uneven textures. This is particularly beneficial for applications where surface quality is critical, such as automotive refinishing or metal fabrication.

3. Versatile Applications

The Multi-Layer Mesh With Welding Spots is compatible with a wide range of tools and machinery, including angle grinders, die grinders, and bench grinders. Its adaptability allows it to be used in various industries, from metalworking and construction to woodworking and automotive repair. Whether you're removing rust, paint, or preparing surfaces for coating, our discs offer reliable performance across multiple applications.

Technical Specifications

- Material: High-quality carbon steel or stainless steel, depending on the application requirements.

- Mesh Count: Available in 60-120 grit options for fine to coarse grinding.

- Dimensions: Standard sizes include 125mm, 150mm, and 225mm, with custom options available.

- Welding Spots: Strategically placed to reinforce the mesh structure and prevent distortion.

- Surface Finish: Smooth and even, ensuring optimal contact with the workpiece.

Industry Applications and Use Cases

Our Multi-Layer Mesh With Welding Spots is widely used in the following industries:

- Automotive Manufacturing: Ideal for removing paint, rust, and old coatings from vehicle bodies before repainting.

- Construction: Used for surface preparation of metal structures, ensuring proper adhesion of coatings and sealants.

- Industrial Maintenance: Efficiently removes scale, oxidation, and debris from machinery parts and equipment.

- Woodworking: Suitable for sanding and smoothing wood surfaces to achieve a professional finish.

Why Choose Anping County Ansheng Wire Meshes Product Co., Ltd.?

With over two decades of experience in the wire mesh industry, Anping County Ansheng Wire Meshes Product Co., Ltd. has established itself as a trusted supplier of high-quality industrial products. Our commitment to innovation and customer satisfaction ensures that every product meets the highest standards of quality and performance.

Advanced Manufacturing Technology

We employ state-of-the-art machinery and rigorous quality control processes to ensure consistency and reliability. Our wire mesh discs are produced using precision engineering techniques, resulting in products that deliver exceptional performance and longevity.

Comprehensive Customer Support

We offer tailored solutions to meet the specific needs of our clients. From product customization to technical support, our team is dedicated to providing a seamless experience. Contact us today to discuss your requirements and receive expert guidance on selecting the right mesh discs for your applications.

How to Use Our Mesh Sanding Discs

Using our mesh sanding discs is straightforward. Simply attach the disc to your grinding tool, ensuring it is securely fastened. Adjust the tool's speed based on the material being worked on, and apply even pressure while moving the disc in a circular motion. For best results, replace the disc when it shows signs of wear or reduced efficiency.

Environmental and Safety Compliance

All our products are manufactured to meet international safety and environmental standards. The Multi-Layer Mesh With Welding Spots is designed to minimize dust generation during use, reducing the risk of respiratory hazards. Additionally, our packaging is eco-friendly, ensuring safe transportation and storage without compromising product integrity.

Ordering and Delivery

Our wire mesh discs are available in bulk quantities to accommodate large-scale production needs. We offer flexible packaging options and reliable shipping services to ensure timely delivery. For more information on pricing and availability, visit our company website or contact our sales team directly.

Customer Testimonials

"The Multi-Layer Mesh With Welding Spots has significantly improved our surface preparation process. The discs last longer and provide a much smoother finish compared to other products we've used." – John D., Automotive Workshop Manager

"As a construction contractor, we rely on these mesh sanding discs for our metalwork projects. Their durability and performance have exceeded our expectations." – Emily R., Construction Supervisor

Frequently Asked Questions (FAQ)

Q: What materials are the mesh sanding discs made from?

A: Our wire mesh discs are made from high-quality carbon steel or stainless steel, depending on the specific application requirements.

Q: Can the discs be customized for specific sizes or grits?

A: Yes, we offer custom manufacturing options to meet your unique specifications. Contact our sales team for more details.

Q: Are the discs compatible with all grinding tools?

A: Our products are designed to fit standard grinding tools, but we recommend checking the tool's specifications before use.

Q: What safety precautions should I take when using the discs?

A: Always wear appropriate personal protective equipment, including safety glasses and gloves. Ensure the tool is properly secured and operated in a well-ventilated area.

Conclusion

The Multi-Layer Mesh With Welding Spots from Anping County Ansheng Wire Meshes Product Co., Ltd. is a reliable solution for industrial grinding and polishing needs. With its advanced design, superior durability, and versatility, our wire mesh discs are an excellent choice for businesses seeking to enhance efficiency and reduce costs. Discover the difference of high-quality mesh sanding discs today.

Visit Our Company Website for more information or to place an order.

Post time: Jul . 21, 2025 02:40