Multi-Layer Mesh With Welding Spots: Durable and Efficient Solution for Industrial Applications

As a leading manufacturer of industrial wire mesh products, Anping County Ansheng Wire Meshes Product Co., Ltd. offers the Multi-Layer Mesh With Welding Spots – a cutting-edge solution designed to meet the demanding requirements of modern industrial applications. This product combines advanced engineering with premium materials to deliver unmatched durability, precision, and efficiency. Explore how this innovative mesh technology can transform your production processes.

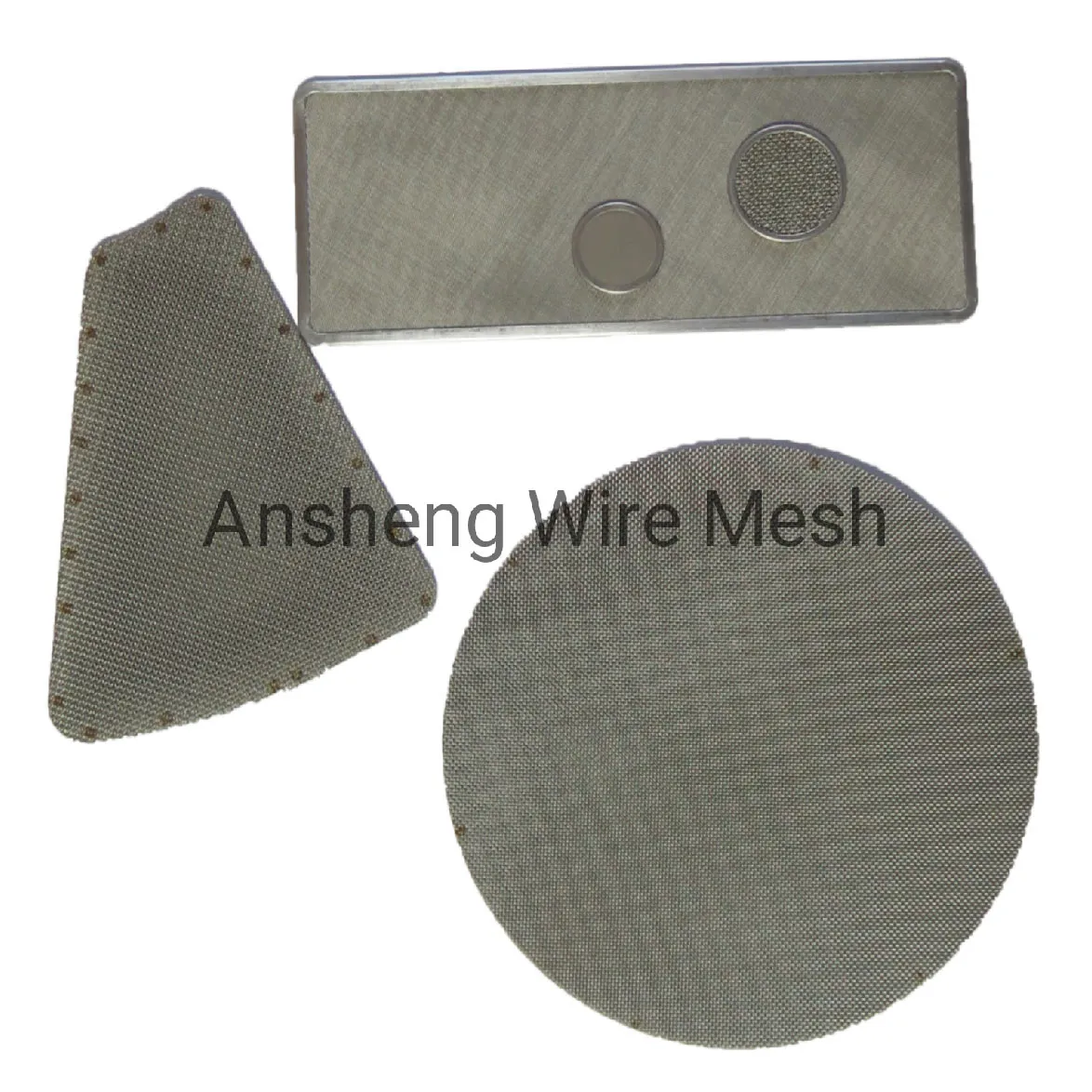

Product Overview: Multi-Layer Mesh With Welding Spots

The Multi-Layer Mesh With Welding Spots is engineered to provide exceptional strength and stability in high-stress environments. This product features a layered construction with strategically placed welding points that enhance structural integrity while maintaining flexibility. It is available in multiple sizes, including 125mm, 150mm, and 225mm mesh sanding discs, catering to a wide range of industrial needs.

Key Features and Technical Specifications

- Multi-Layer Construction: The mesh is composed of multiple layers, ensuring enhanced load-bearing capacity and resistance to deformation.

- Welding Spots: Reinforced welding points provide superior stability, preventing slippage or separation under heavy use.

- Material Quality: Crafted from high-grade wire mesh discs, the product ensures long-term performance and corrosion resistance.

- Size Variants: Available in 125mm, 150mm, and 225mm dimensions to suit specific application requirements.

- Surface Finish: Smooth and even texture for consistent performance in sanding, filtering, and other industrial processes.

Industrial Applications and Market Demand

The Multi-Layer Mesh With Welding Spots is widely used across various industries, including:

- Construction: Ideal for scaffolding, reinforcing structures, and providing stable support in high-load scenarios.

- Manufacturing: Used in sanding, polishing, and surface preparation for metal, wood, and composite materials.

- Automotive: Ensures precision in parts cleaning and surface treatment processes.

- Painting and Coating: Provides an even surface for optimal paint adhesion and finish quality.

The demand for durable, high-performance mesh products has surged in recent years due to the need for cost-effective and long-lasting solutions. Traditional materials often fail to meet the rigorous demands of modern industrial environments, leading to frequent replacements and increased operational costs. Our Multi-Layer Mesh With Welding Spots addresses these challenges by offering a robust alternative that reduces downtime and maintenance expenses.

Company Background and Technical Expertise

Anping County Ansheng Wire Meshes Product Co., Ltd. has been a trusted name in the wire mesh industry for over a decade. Specializing in the production of high-quality mesh products, the company leverages advanced manufacturing technologies and rigorous quality control to ensure every product meets international standards. With a focus on innovation, Anping County Ansheng has developed proprietary techniques to enhance the performance of its mesh solutions, including the Multi-Layer Mesh With Welding Spots.

Our technical team continuously invests in research and development to stay ahead of industry trends. By integrating eco-friendly materials and energy-efficient production methods, we not only deliver superior products but also contribute to sustainable industrial practices.

Product Advantages and Customer Benefits

The Multi-Layer Mesh With Welding Spots offers several key advantages that make it a preferred choice for businesses:

- Enhanced Durability: The multi-layer design and reinforced welding points ensure the mesh withstands heavy use without compromising performance.

- Cost Efficiency: By reducing the frequency of replacements, the product helps businesses lower long-term operational costs.

- Improved Safety: The stable structure minimizes the risk of accidents caused by mesh deformation or breakage.

- Customization Options: We offer tailored solutions to meet the unique requirements of different industries and applications.

Customers have reported significant improvements in productivity and cost savings after adopting our mesh products. One client in the automotive sector noted, "The Multi-Layer Mesh With Welding Spots has drastically reduced our maintenance costs and improved the consistency of our surface preparation processes."

Usage Guidelines and Implementation Strategies

To maximize the benefits of the Multi-Layer Mesh With Welding Spots, it is essential to follow proper usage guidelines:

- Installation: Ensure the mesh is securely fastened to prevent movement during operation. Use compatible hardware for optimal performance.

- Maintenance: Regularly inspect the mesh for signs of wear and replace it as needed to maintain safety and efficiency.

- Customization: Our team can provide tailored recommendations based on your specific application requirements. Contact us for detailed assistance.

For businesses seeking to integrate this product into their workflows, we offer comprehensive implementation support, including technical consultations and on-site training.

Quality Assurance and Environmental Compliance

All Multi-Layer Mesh With Welding Spots products undergo rigorous quality testing to ensure compliance with international standards. They are manufactured using materials that meet RoHS and REACH regulations, ensuring safety for both users and the environment.

We are committed to sustainable practices, and our production processes are designed to minimize waste and energy consumption. By choosing our products, you contribute to a greener industrial future.

Packaging and Shipping Solutions

The Multi-Layer Mesh With Welding Spots is packaged in durable, moisture-resistant containers to protect the product during transportation. For bulk orders, we offer customized packaging options to suit your logistics needs. Our efficient shipping network ensures timely delivery to customers worldwide.

Comprehensive Customer Support

At Anping County Ansheng Wire Meshes Product Co., Ltd., we prioritize customer satisfaction. Our dedicated support team provides:

- Technical Consultation: Expert advice on product selection, application, and troubleshooting.

- On-Site Training: Hands-on guidance to ensure seamless integration of the mesh into your operations.

- After-Sales Service: Prompt assistance with repairs, replacements, and product improvements.

For any inquiries, contact us at +86 139 3202 1555 or visit our official website for more information.

Conclusion and Call to Action

The Multi-Layer Mesh With Welding Spots from Anping County Ansheng Wire Meshes Product Co., Ltd. is a reliable and cost-effective solution for modern industrial challenges. By choosing our product, you gain access to high-quality mesh technology that enhances productivity and reduces long-term costs. Discover the difference today by visiting our product page.

Frequently Asked Questions (FAQ)

Q1: What industries can benefit from the Multi-Layer Mesh With Welding Spots?

A: This product is ideal for construction, manufacturing, automotive, and painting industries, where durability and precision are critical.

Q2: Can the mesh be customized for specific applications?

A: Yes, we offer tailored solutions to meet the unique requirements of different industries and projects.

Q3: How does the welding spot design improve performance?

A: The welding spots enhance structural stability, preventing deformation and ensuring consistent performance under heavy use.

Q4: What certifications does the product have?

A: Our products comply with RoHS and REACH standards, ensuring safety and environmental responsibility.

Q5: How can I place an order or request a sample?

A: Contact us at +86 139 3202 1555 or visit our website to learn more about ordering options.

Post time: Jul . 20, 2025 23:00